Why the Dry Vacuum Graphite Machining Center DC6060G Is the Top Choice for Graphite Processing Enterprises

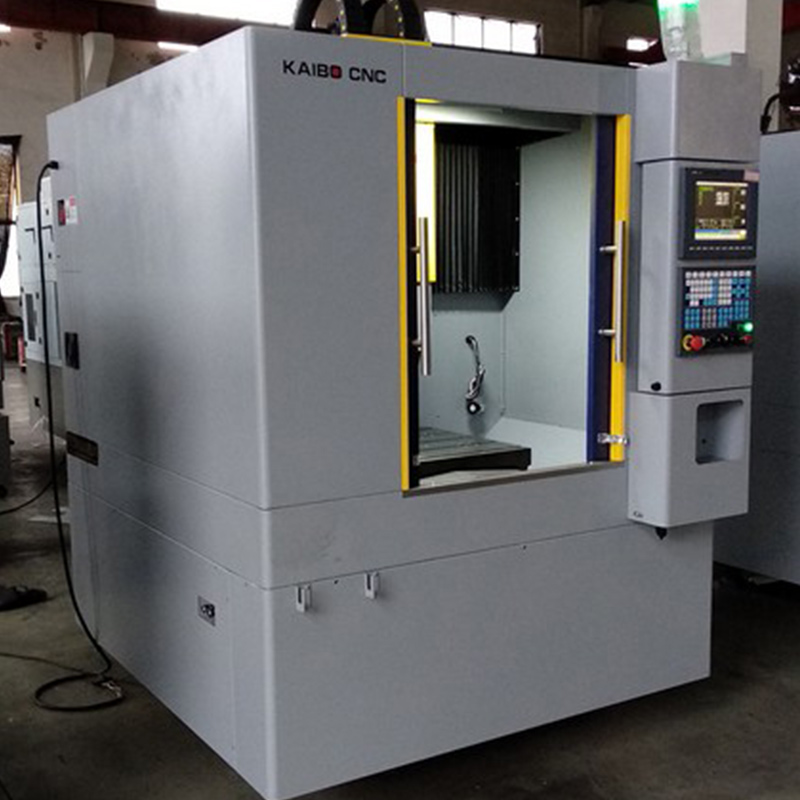

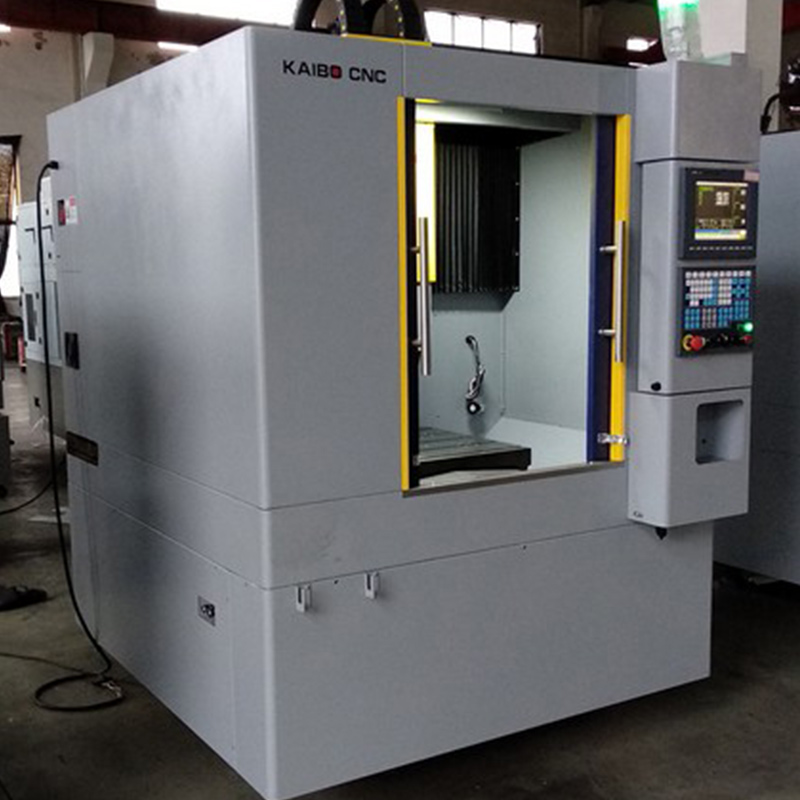

In the graphite processing industry, dust and metal debris contamination have long posed significant challenges. The Dry Vacuum Graphite Machining Center DC6060G emerges as a leading solution, tailored to address these pain points effectively. Built on the proven CNC milling platform DC6060A, this machining center features a fully sealed enclosure design that protects critical machine components and electronic parts from harmful graphite dust ingress. Additionally, it integrates a high-efficiency dust extraction system to collect and remove graphite particles, ensuring a cleaner and safer operating environment. This article delves into the unique design elements and functional advantages that set the DC6060G apart from conventional machining centers. Supported by real-world customer case studies, the discussion highlights how this advanced equipment optimizes graphite processing workflows while minimizing contamination risks. An interactive segment concludes the piece, inviting readers to engage and share insights, underscoring why the DC6060G is the ideal choice for graphite processing enterprises seeking robust, dust-mitigation solutions.

Addressing Graphite Machining Challenges: Why the DC6060G is Your Top Choice

The graphite machining industry has long grappled with a critical issue: managing hazardous dust and metal debris generated during processing. These contaminants not only jeopardize operator health but also compromise the longevity and precision of equipment. Enter the Dry Vacuum Graphite Machining Center DC6060G—a game-changer engineered specifically to tackle these concerns and elevate manufacturing standards worldwide.

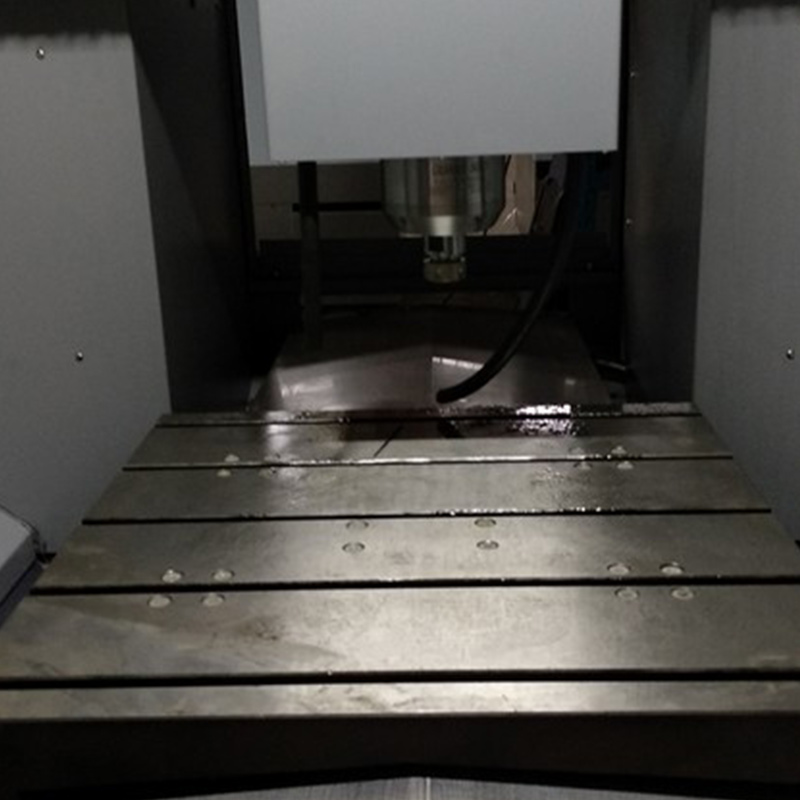

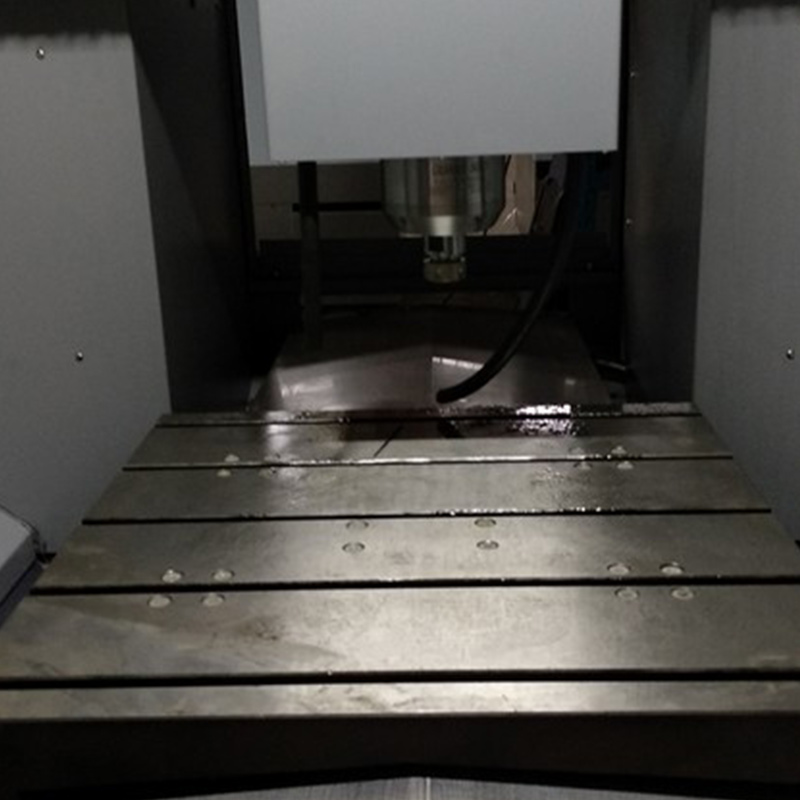

Innovative Full-Sealed Enclosure Design: Keeping Contamination at Bay

Unlike conventional graphite machining centers, which often expose crucial electronic components and mechanical parts to dust infiltration, the DC6060G incorporates a full-sealed enclosure design. This design forms a protective barrier around the machine’s vital systems, effectively shielding them from graphite dust and metal shavings. By preventing contamination, this approach significantly reduces maintenance frequency and downtime.

Industry tests reveal that machines without sealing experience up to 30% faster wear on electronic circuits due to graphite deposition. The DC6060G's sealing mitigates this risk, potentially extending the machine lifespan by over 40% compared to typical setups.

State-of-the-Art Dust Extraction System:Cleaner, Safer Work Environment

Complementing the seal, the DC6060G is fitted with an advanced vacuum-based dust collection system that actively captures graphite powder as it’s generated during milling. This mechanism not only keeps the work area clean but also significantly cuts down airborne particulate concentration—which are notorious for causing respiratory issues among operators.

| Feature |

DC6060G |

Standard Graphite Machining Centers |

| Dust Containment |

Full-sealed enclosure |

Open or partial enclosure |

| Dust Extraction |

Integrated vacuum suction system |

Limited or no dust extraction |

| Equipment Longevity |

Up to 40% longer |

Standard lifespan |

| Operator Safety |

Reduced airborne dust levels |

Higher health risk |

Real-World Success: Client Case Studies

Several leading graphite machining enterprises have integrated the DC6060G into their production lines with remarkable results:

- Precision Improvement: A European graphite component manufacturer reported a 25% increase in dimensional accuracy, attributing this to the machine's stable environment and contamination-free operations.

- Maintenance Reduction: A North American processing plant reduced their machine maintenance time by 35%, largely thanks to the sealed design minimizing dust-induced electrical and mechanical failures.

- Operator Health: A Japanese firm noted a significant decrease in airborne particulate counts in their workshops, improving health conditions and compliance with stricter occupational safety standards.

Take the Next Step: Join the Discussion

Ready to eliminate dust-related challenges in your graphite machining operations? How do your current processes compare with solutions like the DC6060G? We invite professionals, engineers, and decision-makers to share their experiences and ask questions in our interactive forum.

Your input is valuable. Together, we can push the boundaries of efficiency & safety in graphite machining.