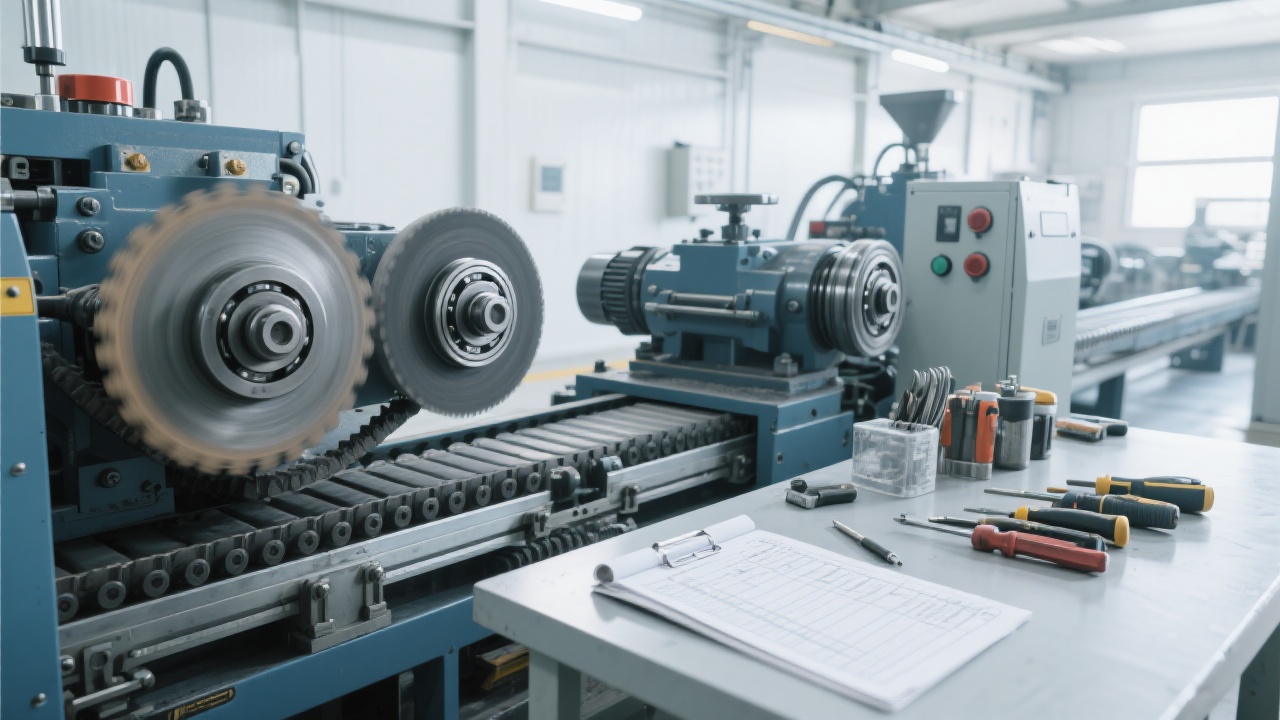

In the field of graphite machining, especially in the new energy battery and mold manufacturing industries, the problem of burrs in graphite milling has always been a headache for engineers. The high brittleness of graphite and the mismatch of processing parameters are the main culprits for this common issue. Let's delve into the root causes and explore effective solutions.

Graphite is a highly brittle material. During the milling process, its inherent brittleness makes it prone to cracking and chipping, resulting in burrs on the machined surface. The high - speed cutting process exacerbates these problems, as the sudden force exerted on the graphite can cause it to break irregularly.

When it comes to graphite milling, tool selection is crucial. PCD (Polycrystalline Diamond) tools have significant advantages. PCD tools offer high hardness, excellent wear resistance, and sharp cutting edges. They can cut through graphite with less force, reducing the likelihood of burrs and chipping. In comparison, traditional carbide tools may wear out quickly and are more likely to cause surface damage due to their relatively lower hardness.

The feed rate plays a vital role in graphite milling. An improper feed rate can lead to excessive cutting force, which in turn causes burrs and poor surface finish. Generally, a lower feed rate is recommended for graphite milling. For example, when using a PCD tool with a diameter of 6mm, a feed rate of 0.05 - 0.1mm/tooth can significantly improve the surface quality. Table 1 below shows the relationship between feed rate and surface roughness:

| Feed Rate (mm/tooth) | Surface Roughness (μm) | |

|---|---|---|

| 0.05 | 1.2 | |

| 0.1 | 2.0 |

A wet flush system is a game - changer in graphite milling. It can effectively reduce cutting heat and remove graphite dust. During the cutting process, a large amount of heat is generated, which can cause thermal expansion of the graphite and the tool, leading to dimensional inaccuracies and more burrs. The wet flush system uses a coolant to flush the cutting area, taking away the heat and graphite dust. For instance, using a water - based coolant with a flow rate of 10 - 20L/min can keep the cutting area clean and cool, reducing the occurrence of burrs and chipping.

Here are some typical process parameters and practical tips for graphite milling:

By following these parameters and tips, engineers can quickly identify and solve processing anomalies.

Our wet flush system, combined with a fully - sealed design, can significantly enhance the stability of the machine tool. This not only improves the processing quality but also extends the service life of the equipment. With better stability, you can achieve higher - precision graphite machining, reducing waste and improving production efficiency.

If you are an engineer in the new energy battery or mold manufacturing industry, and you are looking to improve graphite machining quality and efficiency, don't miss out on our advanced wet flush system and machine tool solutions. Click here to learn more!