In the highly specialized field of graphite machining, controlling dust-induced corrosion and contamination remains a persistent challenge for manufacturers. The wet-flush graphite machining center DC6060G, developed as an enhanced version of the DC6060A CNC milling machine, stands as a cutting-edge solution designed specifically to address these industry pain points. Its innovative features, including a full-sealed enclosure and a sophisticated wet flushing system, redefine operational efficiency and machine longevity in graphite processing.

Graphite dust, fine and pervasive, infiltrates every nook inside conventional machining centers, causing accelerated wear and corrosion of mechanical parts and sensitive electronic components. Traditional dry machining equipment often requires frequent maintenance and replacement of parts due to high contamination levels, resulting in costly downtime and inconsistent production quality. This industry-wide problem demands not only a reactive but proactive engineering approach.

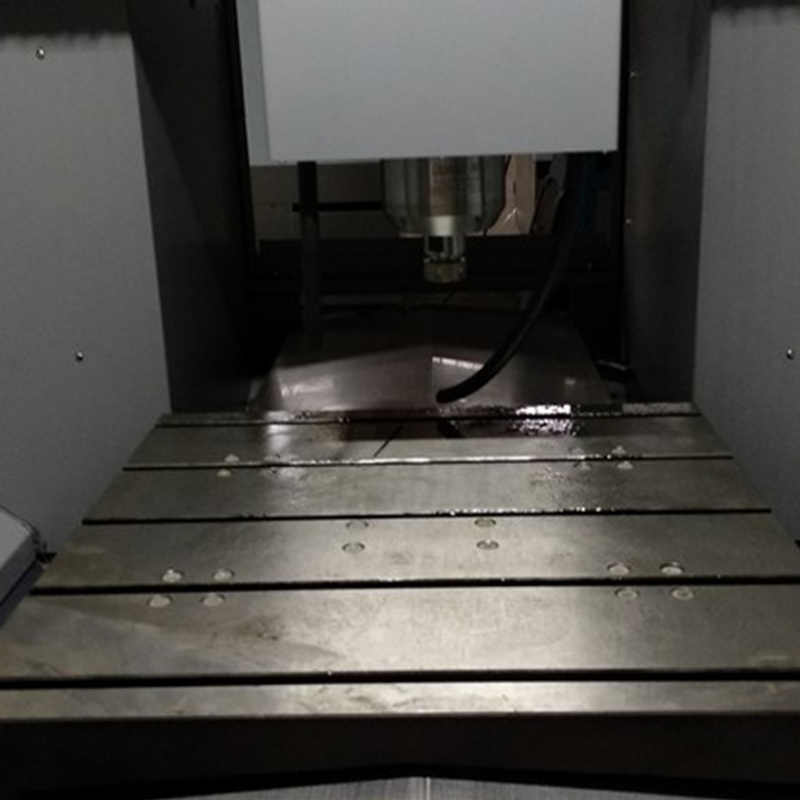

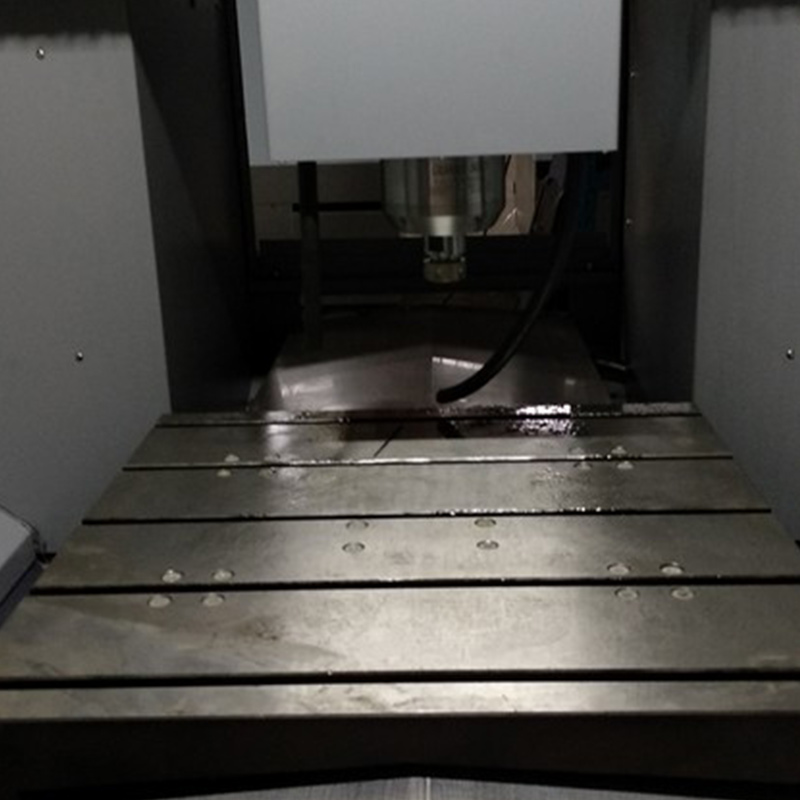

The DC6060G emerges from the trusted DC6060A CNC milling platform, optimized specifically for graphite processing. Structural reinforcements coupled with corrosion-resistant materials extend the operational lifespan significantly. Most notably, the machine incorporates a fully sealed enclosure that isolates sensitive components from graphite dust exposure.

| Feature | Benefit |

|---|---|

| Full-Sealed Enclosure | Prevents graphite dust infiltration, protecting mechanical and electronic parts |

| Wet Flushing System | Effectively washes away graphite particles during machining |

| Enhanced Cooling & Lubrication | Improves tool life and processing precision |

The DC6060G's integrated wet flushing system is engineered to directly counteract graphite dust accumulation by continuously washing machining zones with coolant. This process significantly reduces airborne dust and residues remaining on machine surfaces. The flushing liquid simultaneously cools cutting tools, enhancing their durability and machining accuracy.

This innovative approach has led to a reported 30% reduction in tool replacement frequency and a 25% improvement in average machine uptime among users, according to recent industry feedback.

A leading electronics materials manufacturer in Germany integrated the DC6060G into their graphite electrode production line. Within six months, they observed:

These results translated into a measurable uplift in their operational efficiency and output stability, validating the DC6060G’s technical merits.

Compared with traditional dry graphite machining centers, the DC6060G offers:

1. Comprehensive dust protection mechanisms ensuring longer equipment lifecycle.

2. Enhanced environmental and operator safety through significant dust reduction.

3. Elevated machining accuracy and throughput due to the cooling and cleaning effect of wet flushing.

4. Proven reliability and customer satisfaction backed by successful global deployments.

In industries where precision and durability define success, the DC6060G represents a transformative upgrade for graphite machining operations.