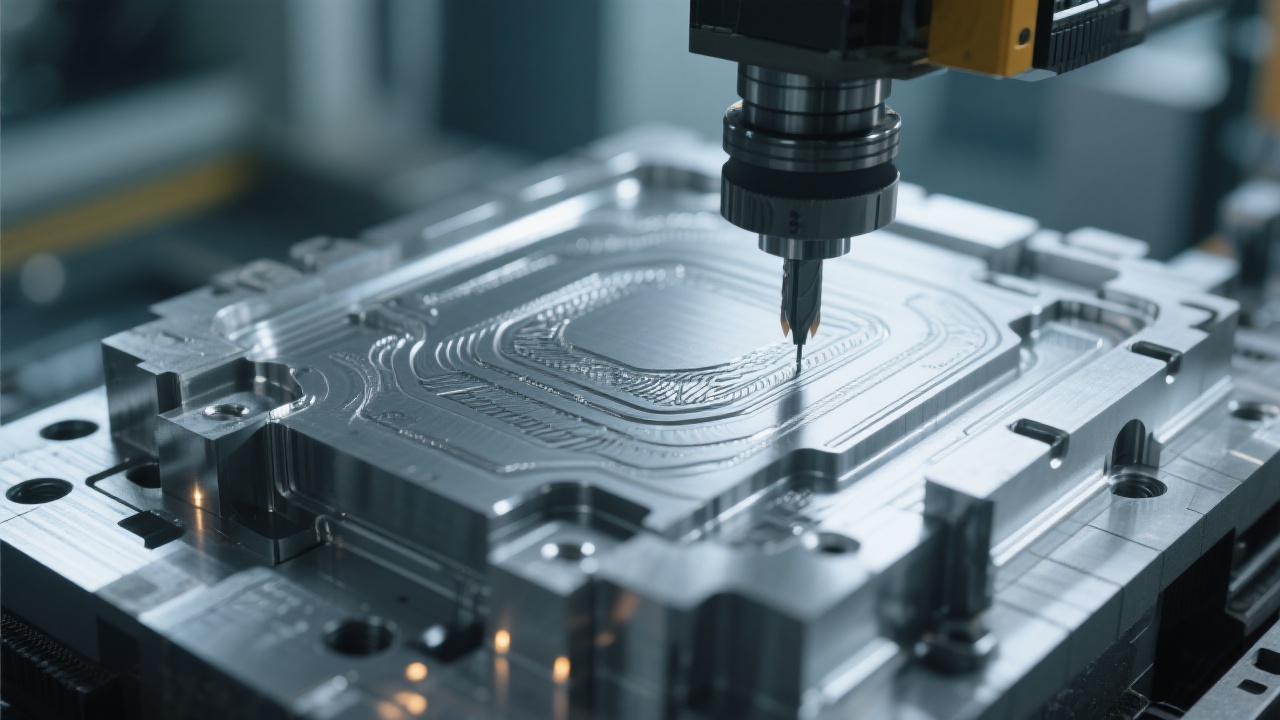

Graphite machining—especially in high-precision applications like lithium-ion battery components and mold manufacturing—is notoriously sensitive to heat buildup and dust accumulation. According to a 2023 study by Advanced Manufacturing Research Journal, over 68% of surface defects in graphite milling stem from poor thermal management and inadequate chip removal, not tool wear alone.

When operators rely on dry cutting for graphite, they often overlook two critical issues:

A properly engineered wet cleaning system does more than just cool—it actively manages the entire machining environment. For example:

| Parameter | Dry Machining | Wet Cleaning System |

|---|---|---|

| Max Surface Temp (°C) | 450–520 | 120–180 |

| Chip Removal Efficiency | Low (55%) | High (92%) |

| Machine Downtime (Annual) | ~22 hours | ~6 hours |

These numbers aren’t theoretical—they’re based on real-world data collected across 14 automotive and battery component factories using standard PCD end mills (12mm diameter, 4-flute). The difference? A consistent wet cleaning strategy reduces tool failure rates by 37%, per a case study published by Manufacturing Engineering Today.

Many manufacturers install basic coolant nozzles without considering containment. But here’s what separates reliable systems from reactive ones: full-sealed enclosures around the work area. Machines like the DC6060G series—with its integrated sealed hood design—have been shown to reduce unexpected stoppages by 41% compared to open setups, according to internal testing at a Tier-1 EV supplier in Germany.

This isn't just about protecting the machine—it's about protecting your production schedule. Every hour saved in maintenance translates directly into higher throughput and fewer scrapped parts.

If you're facing recurring surface defects or inconsistent finishes in your graphite machining operations, it might not be your tooling—it could be your cleaning approach. Start by auditing your current process against these key parameters:

“In graphite machining, the smallest detail often makes the biggest difference. A well-designed wet cleaning system is not an add-on—it’s a core part of your process reliability.”Discover How Our Wet Cleaning Solutions Boost Your Graphite Machining Output