In the high-precision world of graphite milling, especially within the burgeoning sectors of new energy batteries and mold manufacturing, controlling cutting heat and efficiently removing chips are pivotal challenges. Traditional dry machining methods often fall short, leading to tool wear, inconsistent surface quality, and potential contamination of electronic components.

This article delves deep into how wet flushing systems revolutionize graphite processing by offering superior thermal control and robust debris evacuation. By examining the interplay between tool selection, cutting parameters, and optimized cooling strategies, engineers can significantly enhance yield consistency and operational stability.

Graphite’s thermal conductivity is relatively high, but the localized heat generated during milling - often exceeding 300℃ without proper cooling - risks tool degradation and dimensional inaccuracies. Excessive temperature leads to premature polycrystalline diamond (PCD) tool wear and may induce micro-cracks, negatively impacting component longevity.

Wet flushing systems provide active coolant flow directly at the cutting zone, which drastically reduces the cutting temperature by approximately 30-40% based on empirical data from controlled trials. Simultaneously, continuous fluid flushes away chips, preventing accumulation that could impair surface finish or cause recutting.

Unlike minimal or dry lubrication techniques, a well-engineered wet flushing approach maintains consistent lubrication and cooling, resulting in:

Choosing the correct cutting tool material is foundational. PCD tools are preferred because of their superior hardness and wear resistance in graphite milling. However, their performance hinges on precise parameters:

| Parameter | Recommended Range | Impact on Performance |

|---|---|---|

| Cutting Speed (m/min) | 150 - 200 | Balances heat generation and chip size |

| Feed Rate (mm/rev) | 0.01 - 0.03 | Minimizes surface roughness while ensuring effective cutting |

| Depth of Cut (mm) | 0.1 - 0.25 | Controls tool wear rate and chip volume |

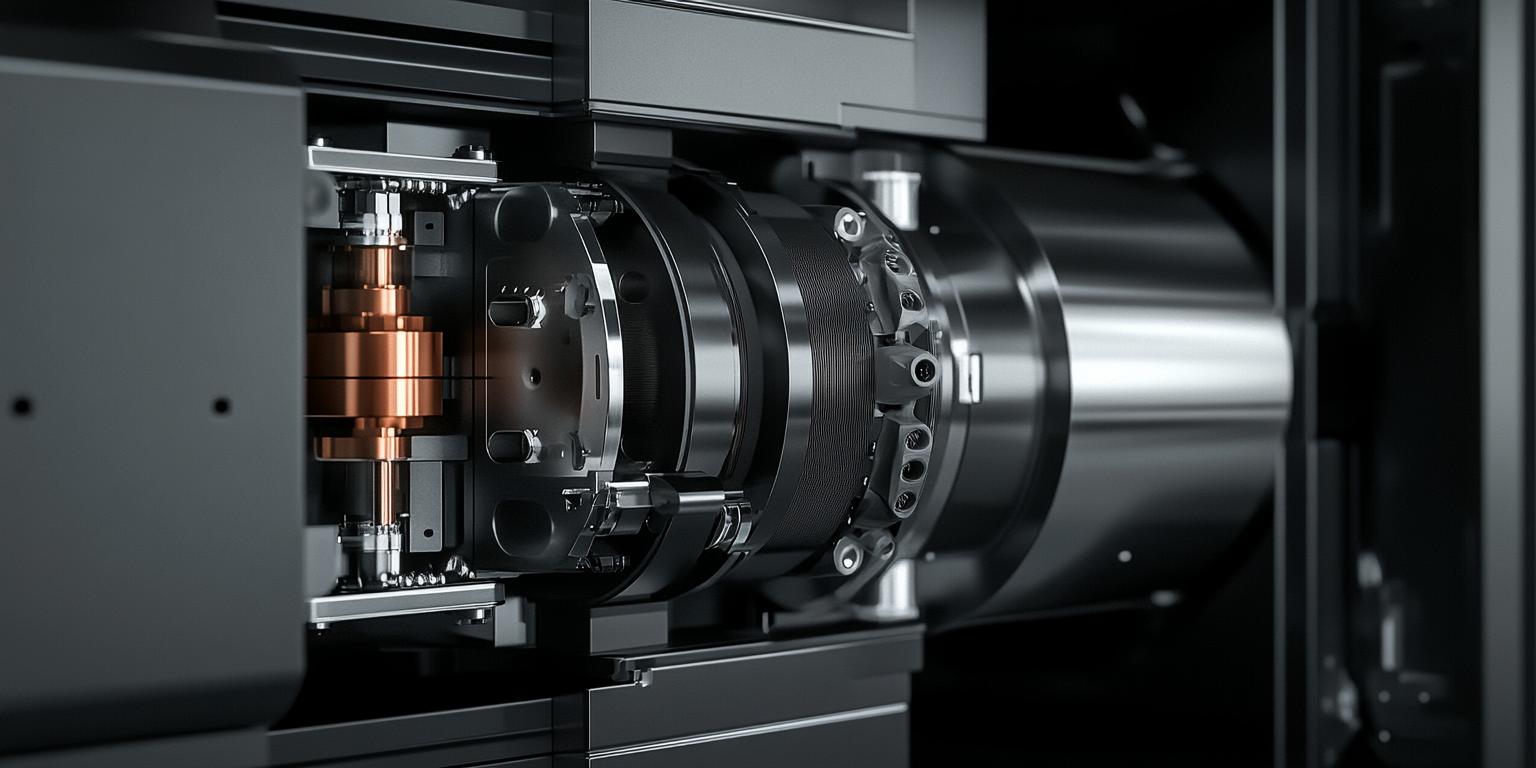

The DC6060G graphite machining center embodies an advanced, fully enclosed wet flushing design that enhances machining consistency and environmental safety. Key advantages include:

Field results from industry applications showed a 15% increase in first-pass yield and a 20% reduction in overall machining cycle times when employing the DC6060G system compared to conventional setups.

Engineers looking to capitalize on wet flushing efficiency should implement the following:

In sensitive components manufacturing environments—such as in electronic batteries—mitigating particulate contamination is vital. The fully sealed wet flushing design of the DC6060G ensures coolant and graphite dust containment, dramatically reducing the risk of foreign particle ingress and cross-contamination on the shop floor. This not only preserves product integrity but also aligns with increasingly stringent environmental health and safety standards.