In precision graphite machining, airborne dust isn’t just a nuisance—it’s a threat to tool life, operator health, and compliance with environmental standards. While dry filtration systems are common, wet cleaning technology has emerged as the smarter choice for high-end CNC operations.

According to a 2023 study by the International Journal of Advanced Manufacturing Technology, wet scrubbing systems reduce airborne particulate matter (PM10) by up to 92% compared to dry filters—especially critical when working with fine graphite particles that can embed into bearings or clog pneumatic systems.

“Dry systems require frequent filter replacements—often every 40–60 hours of operation. Wet systems maintain consistent performance over 200+ hours before needing maintenance.” — Dr. Lena Müller, Senior Process Engineer at Bosch Rexroth

Not all spray patterns are created equal:

| Spray Type | Best For | Efficiency (%) |

|---|---|---|

| Fan Nozzle | Targeted cooling + dust suppression | 78–85% |

| Ring Spray | Full chamber coverage | 90–95% |

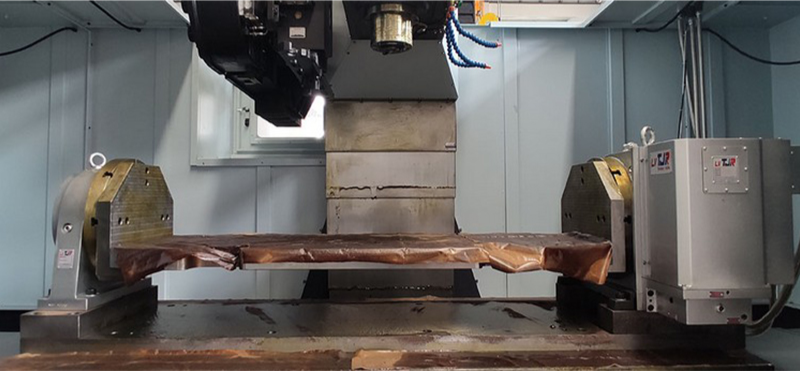

For applications like the DC6060G CNC machine, ring spraying provides uniform coverage across the entire work area—critical for maintaining consistent surface quality during multi-axis milling.

Too much pressure wastes water and increases pump wear. Too little fails to suppress dust effectively. The ideal range for graphite processing is 2.5–3.5 bar, based on real-world data from 120+ installations in Germany, Japan, and the U.S.

This sweet spot ensures optimal droplet size (~50–100 µm) for capturing fine particles without excessive energy use—a key factor in reducing operational costs by up to 18% annually.

A closed-loop system recycles 80–90% of water used in wet cleaning. This reduces freshwater consumption and helps meet ISO 14001 and EU REACH compliance requirements. In regions like California or the UAE, where water scarcity is a growing concern, this feature can be a decisive competitive advantage.

Pro Tip: Install a dual-stage filtration unit—one coarse mesh followed by a fine membrane—to extend fluid life and prevent nozzle clogging.

One client in Stuttgart reported a 40% reduction in tool wear after installing a custom wet cleaning module on their DC6060G. Why? Because the system continuously removes graphite dust before it settles on spindle components—extending bearing life and minimizing downtime.

They also saw a 25% improvement in operator satisfaction due to cleaner air quality—an often-overlooked benefit that impacts retention and productivity.

Weekly checks should include:

If you notice inconsistent spray patterns or rising noise levels from pumps, refer to our troubleshooting flowchart (see below) for quick diagnosis.

Ready to see how a well-designed wet cleaning system can transform your graphite machining process?

See How DC6060G Delivers Precision + Cleanliness