Graphite processing is a crucial industry, but it comes with significant challenges, primarily the issue of dust and metal shavings pollution. These pollutants not only pose a threat to the health of workers but also can cause damage to processing equipment, leading to increased maintenance costs and reduced equipment lifespan. In fact, statistics show that in traditional graphite processing centers, up to 30% of equipment failures are related to dust and metal shavings contamination.

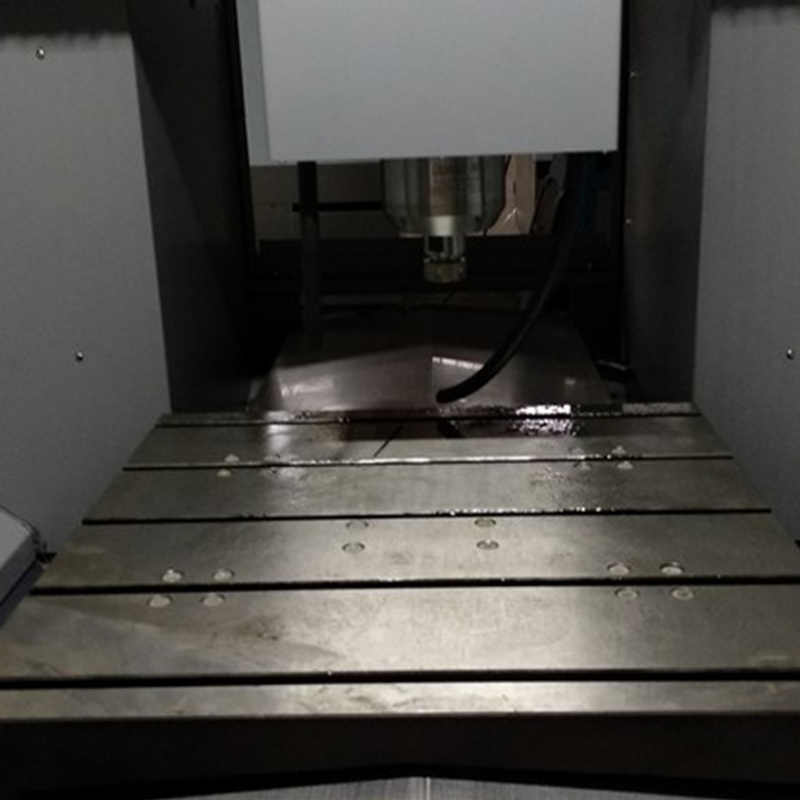

The Dry Vacuum Graphite Machining Center DC6060G is an upgraded version based on the CNC milling machine DC6060A. It has a fully sealed enclosure design, which provides excellent protection. The fully sealed enclosure can prevent dust and metal shavings from escaping into the working environment, effectively reducing pollution levels. According to tests, this design can reduce dust emissions by up to 90% compared to ordinary processing centers.

One of the most remarkable features of the DC6060G is its advanced dust collection device. This device can effectively collect and remove graphite dust generated during the processing. It has a high - efficiency filtration system that can capture particles as small as 0.1 microns, ensuring that the air inside the processing center remains clean. In comparison, ordinary processing centers often have difficulty dealing with fine dust particles, which can accumulate over time and affect the processing quality.

When compared to ordinary graphite processing centers, the DC6060G stands out in many aspects. Firstly, in terms of environmental protection, as mentioned above, its dust collection and enclosure design significantly reduce pollution. Secondly, in terms of processing quality, the clean working environment ensures more stable processing parameters, reducing the occurrence of processing defects. Tests have shown that the product qualification rate of DC6060G can reach up to 95%, while that of ordinary processing centers is only around 80%.

Let's take a look at some real - world examples. A graphite processing factory in Germany replaced its old processing center with the DC6060G. After three months of operation, they found that the equipment maintenance frequency decreased by 40%, and the production efficiency increased by 20%. Another factory in Japan reported that the quality of their graphite products improved significantly after using the DC6060G, which helped them gain more high - end customers.

Are you considering upgrading your graphite processing equipment? Do you have any questions about the DC6060G? We invite you to leave your comments below or contact our sales team. Discover how the DC6060G can revolutionize your graphite processing operations and take your business to the next level!

Don't miss out on the opportunity to enhance your graphite processing efficiency and quality. Contact us today to learn more about the DC6060G and start your journey towards a more advanced and environmentally - friendly processing solution!