In the graphite processing industry, ordinary CNC milling machines often face the pain points of graphite dust and metal chip pollution. These pollutants can cause serious corrosion and contamination to machine parts and electronic components, shortening the service life of the machine and affecting the health of operators. In response to these problems, the dry vacuum graphite machining center DC6060G has emerged as an upgraded model of the CNC milling machine.

The DC6060G is designed based on the CNC milling machine DC6060A. The R & D team aimed to solve the pollution problems faced by ordinary CNC milling machines. Their goal was to create a machine that could not only improve the machining accuracy and efficiency but also effectively protect the machine and the working environment. After in - depth research and continuous improvement, the DC6060G was finally developed.

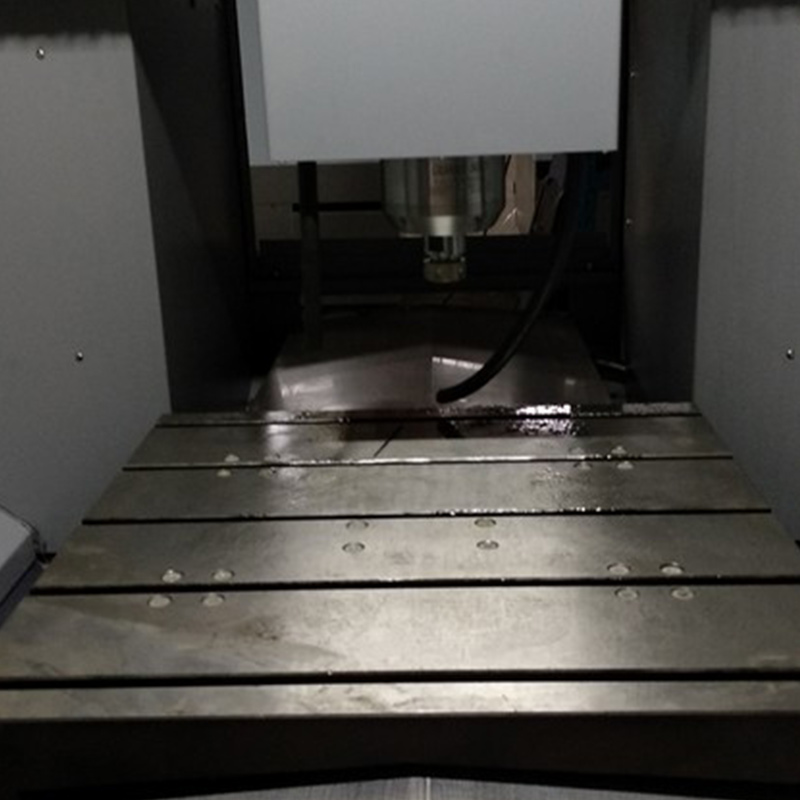

Full - Sealed Cover Design: The internal full - sealed cover design of the DC6060G is a significant upgrade. In ordinary CNC milling machines, graphite dust and metal chips can easily enter the internal parts of the machine, causing corrosion and wear. However, the full - sealed cover of the DC6060G can effectively block these pollutants. The principle is that the cover forms a closed space around the machining area, preventing dust and chips from spreading. This design has a crucial impact on extending the machine's service life. According to our data, the service life of the DC6060G can be extended by about 30% compared with ordinary CNC milling machines.

Dust Collection Device: The DC6060G is equipped with a high - efficiency dust collection device. This device works by generating a strong suction force to collect graphite dust during the machining process. Compared with ordinary CNC milling machines, which often have poor dust - removal capabilities, the dust collection efficiency of the DC6060G can reach more than 95%. This not only improves the working environment but also reduces the risk of respiratory diseases for operators. For example, in a graphite processing workshop, after using the DC6060G, the dust concentration in the air decreased from 10 mg/m³ to less than 1 mg/m³.

After using the DC6060G, the machine failure rate has been significantly reduced. In a large - scale graphite processing factory, the machine failure rate of ordinary CNC milling machines was about 15% per year, while after replacing with the DC6060G, the failure rate dropped to less than 5%. In terms of operator health, the incidence of respiratory diseases among operators decreased by 60%.

One of our customers, a medium - sized graphite processing enterprise, used to face frequent machine breakdowns and high employee absenteeism due to health problems. After purchasing the DC6060G, the production efficiency increased by 20%, and the cost of machine maintenance decreased by 30%. The enterprise also received praise from relevant environmental protection departments for improving the workshop environment.

If you are currently in the consideration stage of purchasing a graphite machining center, the dry vacuum graphite machining center DC6060G is definitely worth your in - depth understanding. Its significant upgrade advantages can bring you higher production efficiency, lower maintenance costs, and a better working environment. For more product information, please contact us via the following methods: