In the graphite machining industry, machine tools often face significant challenges from graphite dust and metal chips. These contaminants can cause corrosion and damage to machine parts and electronic components, leading to frequent breakdowns, increased maintenance costs, and reduced production efficiency. According to industry statistics, machines in graphite processing environments without proper protection can experience a 30% increase in downtime and a 20% reduction in overall productivity.

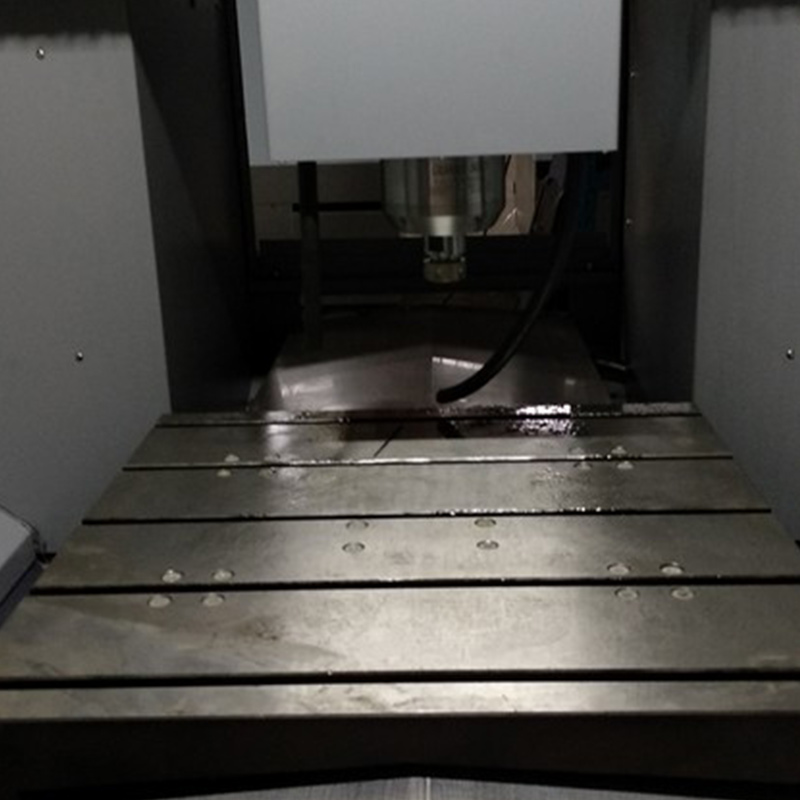

The Dry Vacuum Graphite Machining Center DC6060G is designed based on the CNC milling machine DC6060A, specifically engineered to address the issues of dust and chip contamination. This state - of - the - art machine offers exceptional protection, ensuring smooth and efficient production processes.

One of the key features of the DC6060G is its full - sealed enclosure design. This design effectively prevents graphite dust and metal chips from entering the machine, protecting critical components such as machine parts and electronic elements from corrosion and pollution. With this advanced protection, the machine can operate continuously for up to 800 hours without major breakdowns, significantly reducing the downtime by up to 70% compared to non - protected machines. This means that production efficiency can be increased by approximately 35%, allowing businesses to meet their production targets more effectively.

In addition to the full - sealed enclosure, the DC6060G is equipped with a high - performance dust vacuum system. This system works by creating a powerful suction force that captures and removes graphite dust during the machining process. By keeping the working environment clean, it ensures the machining accuracy can be maintained within a tolerance of ±0.01mm, which is crucial for producing high - quality graphite products. The dust collection efficiency of this system can reach up to 95%, effectively preventing dust from accumulating on the workpiece and tools, thus improving the overall product quality.

When compared with other similar products in the market, the DC6060G stands out for its superior protection performance. While some competing machines may offer only partial protection or have less efficient dust collection systems, the DC6060G's full - sealed enclosure and high - efficiency vacuum system provide comprehensive and reliable protection. This results in lower maintenance costs, longer machine lifespan, and higher production yields. For example, in a side - by - side comparison, the DC6060G reduced maintenance costs by 40% compared to a leading competitor over a one - year period.

Many customers have already benefited from the DC6060G. For instance, a graphite manufacturing company in Germany reported a 50% increase in production capacity after installing the DC6060G. The reduced downtime and improved product quality allowed them to take on more orders and expand their business. Another customer in Japan was able to reduce their scrap rate from 10% to 2% thanks to the precise machining and dust control provided by the DC6060G.

Ready to revolutionize your graphite machining operations? Contact us today to learn more about the Dry Vacuum Graphite Machining Center DC6060G or to request a free trial!