The increasing demand for precision and efficiency in graphite machining has accelerated the need for advanced, reliable CNC machining centers. The DC6060G Wet Flush Graphite Machining Center, engineered based on the well-regarded DC6060A CNC milling platform, stands out as a breakthrough solution designed specifically to tackle the unique challenges of graphite processing.

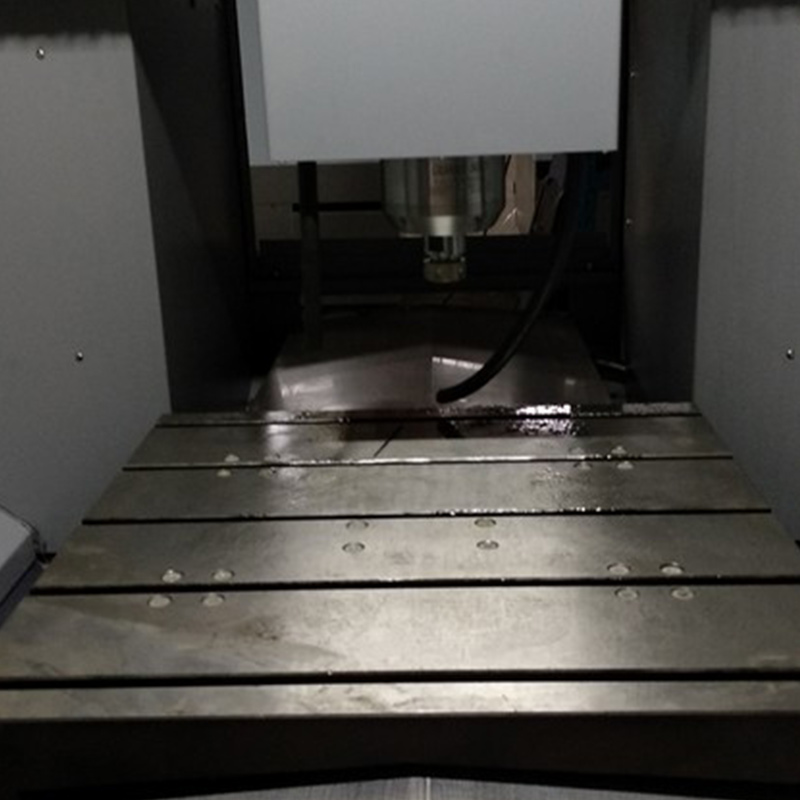

The DC6060G inherits its core structural sturdiness and precision elements from the trusted DC6060A milling machine, widely known for its robust frame and smooth axis motion control. This heritage ensures exceptional machine rigidity, which is critical for maintaining tight tolerances in graphite components highly sensitive to vibration and thermal variations.

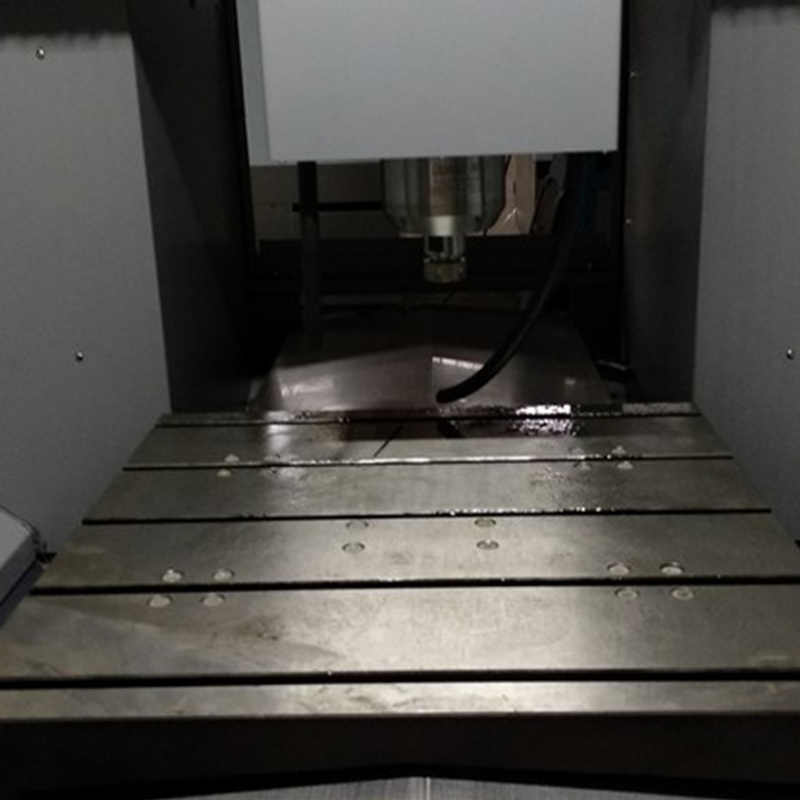

Building on this foundation, the DC6060G integrates a cutting-edge fully sealed enclosure combined with an advanced wet flushing system. These features are specially optimized to address the detrimental effects of graphite dust and metal chips during machining, traditionally responsible for contamination, corrosion, and reduced tool life.

| Feature | Benefit |

|---|---|

| Fully Sealed Enclosure | Prevents graphite dust infiltration, protecting internal components from corrosion and wear. |

| Efficient Wet Flush System | Consistently clears graphite debris and metal chips instantly, ensuring a contaminant-free machining zone. |

| Enhanced Cooling and Lubrication | Optimizes tool life and machining accuracy by maintaining proper thermal control. |

| Improved Workplace Safety | Reduces airborne dust, leading to better environmental compliance and operator health. |

In controlled comparative trials, the DC6060G exhibited a up to 30% reduction in tool wear versus traditional dry machining centers, attributed to its wet flush cooling capabilities. Additionally, dust accumulation inside the machine was reduced by over 85%, significantly lowering maintenance intervals and downtime.

Graphite part dimensional accuracy improved, regularly achieving tolerances within ±0.01 mm, thanks to the stable cutting environment maintained by the wet flushing system and sealed design. Such precision translates directly into fewer rejects and less rework, strongly impacting overall operational costs.

“Since integrating the DC6060G into our production line, we have observed a significant improvement in both machining quality and throughput. The full enclosure and wet flushing have eliminated dust-related issues, drastically improving our equipment uptime and operator comfort.”

– Production Manager, Precision Graphite Components Ltd.

The DC6060G is ideally suited for high-volume graphite machining applications such as electrodes for EDM machines, heat sinks, battery components, and semiconductors. Its advanced protection against particulate contamination and cooling efficacy makes it indispensable for manufacturers demanding high precision and minimal downtime.

We invite you to consider:

Engaging with our specialists can help uncover customized solutions that align with your operational goals.

For detailed technical specifications and personalized consultation, contact our experts today.