In the graphite processing industry, dust generation and equipment wear are major challenges that affect both operational efficiency and worker safety. Traditional machining methods often fail to address these issues effectively, leading to increased maintenance costs, reduced machine lifespan, and compromised working environments. The DC6060G Wet Washing Graphite Machining Center offers a revolutionary solution with its advanced design and integrated wet washing system, addressing these long-standing problems with precision and reliability.

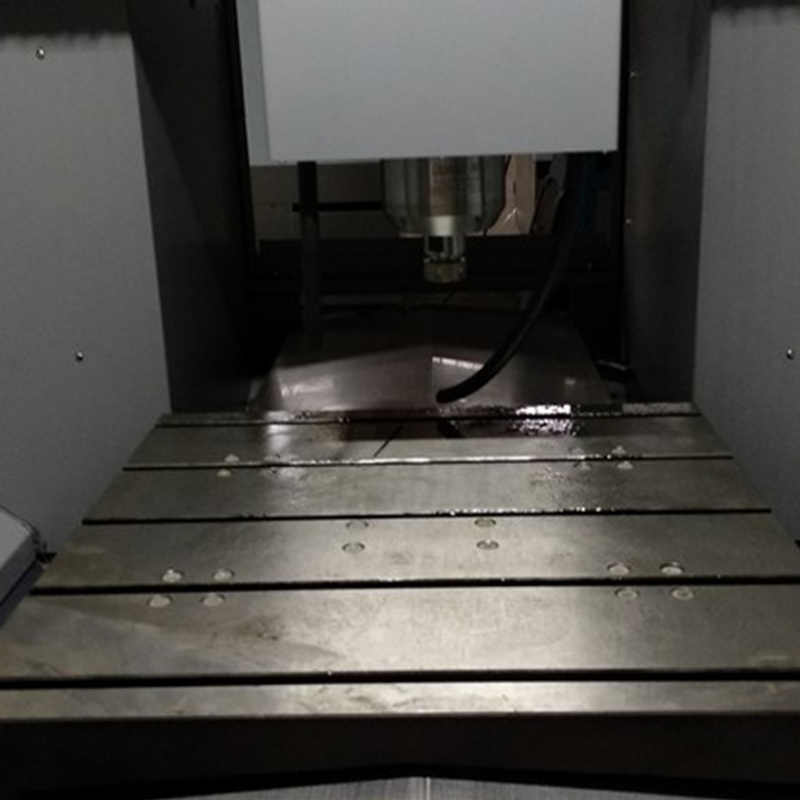

Designed specifically for high-precision graphite machining, the DC6060G integrates a series of optimized features that enhance performance and reduce environmental impact. Unlike conventional CNC milling machines, which often rely on dry cutting techniques, the DC6060G employs a wet washing system that minimizes airborne dust and prevents tool wear caused by fine particulate accumulation.

| Feature | Advantage |

|---|---|

| Wet Washing System | Reduces dust emissions by up to 90% |

| Full Sealing Enclosure | Prevents dust leakage and protects operators |

| High-Precision Control | Ensures consistent quality and reduces rework |

The full sealing enclosure is a critical component of the DC6060G’s design, ensuring that all machining processes take place within a controlled environment. This not only prevents dust from escaping into the workspace but also maintains stable internal conditions, improving machine accuracy and longevity. According to field data, the use of such enclosures can extend machine life by up to 30% compared to traditional setups.

Moreover, the sealing structure is designed with easy access points for maintenance and inspection, ensuring that operators can perform necessary checks without compromising the integrity of the system. This balance between protection and accessibility makes the DC6060G a preferred choice for industrial applications where both safety and efficiency are paramount.

The wet washing system in the DC6060G operates by continuously spraying a fine mist of water or coolant during the machining process. This method not only suppresses dust but also cools the cutting tools, reducing thermal stress and extending their service life. In addition, it helps to flush away debris immediately after cutting, maintaining a clean work area and minimizing downtime for manual cleaning.

According to a case study conducted at a leading graphite manufacturing facility, the implementation of the DC6060G resulted in a 25% increase in overall productivity and a 40% reduction in maintenance frequency. These improvements highlight the system's ability to deliver sustainable operational benefits over time.

A major electronics manufacturer in Southeast Asia recently adopted the DC6060G to improve their graphite electrode production process. Prior to this upgrade, the company faced frequent machine stoppages due to dust buildup and inconsistent product quality. After integrating the DC6060G, they reported a significant improvement in both output consistency and operator safety. The wet washing system proved to be a game-changer, allowing them to meet stringent quality standards while maintaining a clean and safe working environment.

With its combination of advanced dust management, precision control, and user-friendly design, the DC6060G stands out in the competitive landscape of graphite machining solutions. It addresses the core pain points of the industry—dust pollution, equipment degradation, and operational inefficiency—while offering a scalable and future-proof platform for manufacturers looking to optimize their production lines.

For companies seeking a reliable, high-performance machining solution, the DC6060G represents a smart investment that delivers measurable returns in terms of productivity, safety, and cost savings.