In the high-precision manufacturing of graphite components, corrosion and contamination are persistent challenges that can significantly impact machine longevity, accuracy, and overall productivity. The DC6060G Wet-Flush Graphite Machining Center, built upon the reliable foundation of the DC6060A CNC Milling Machine, offers an advanced solution tailored specifically for wet machining environments. This article delves into the core technologies behind the DC6060G, highlighting its superior design in preventing damage from graphite dust and metal shavings, ensuring long-term performance and precision.

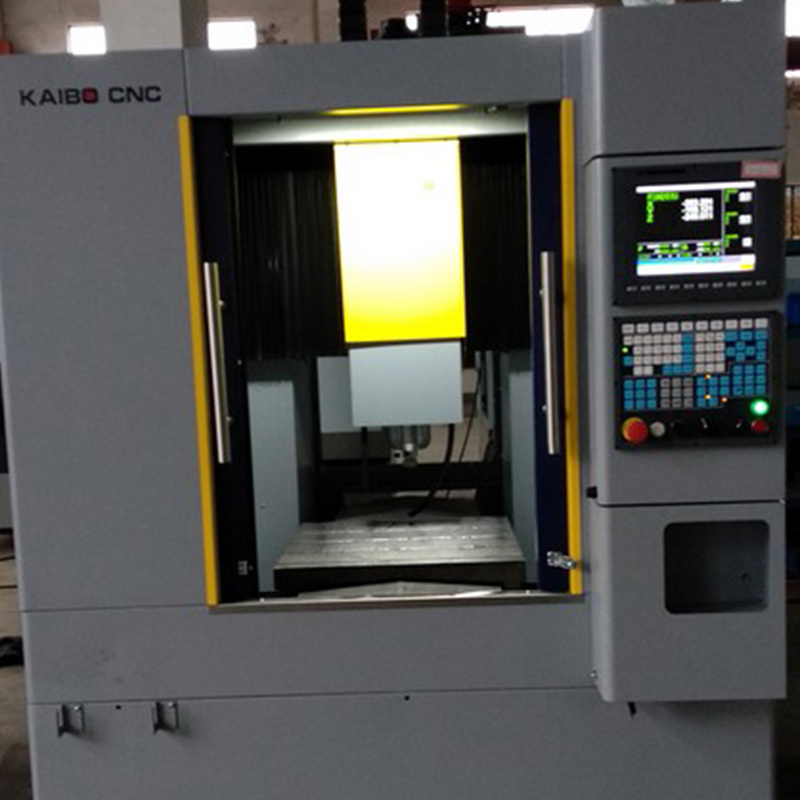

The DC6060G is a direct evolution of the well-established DC6060A model, integrating enhanced features to meet the unique demands of graphite processing. With a focus on precision control and user-friendly operation, the DC6060G maintains the reliability of its predecessor while introducing innovations that address common issues faced by traditional machining centers.

One of the key improvements is the implementation of a fully sealed enclosure, which acts as a protective barrier against harmful particles. This design ensures that internal components, including sensitive electronic systems, remain free from contamination, thus extending the machine's service life and maintaining consistent performance over time.

The heart of the DC6060G’s effectiveness lies in its wet-flush system, a highly efficient mechanism designed to remove fine graphite dust and metal chips during the machining process. Unlike conventional dry systems, which often leave residue and cause gradual wear, the wet-flush approach continuously washes away debris, keeping the work area clean and the machine components protected.

According to field data collected from multiple users, the DC6060G reduces dust accumulation by up to 85% compared to standard machining centers. This not only minimizes maintenance requirements but also improves the quality of finished parts, as contaminants no longer interfere with cutting accuracy.

| Feature | DC6060G | Standard Machine |

|---|---|---|

| Dust Removal Efficiency | 85% | 40% |

| Maintenance Interval | Every 500 hours | Every 200 hours |

| Precision Stability | ±0.02mm | ±0.05mm |

A leading manufacturer in the aerospace industry reported significant improvements after switching to the DC6060G. Previously, their machines required frequent cleaning and repairs due to graphite dust buildup, which led to downtime and reduced part quality. After implementing the DC6060G, they saw a 70% reduction in maintenance costs and a 30% increase in production efficiency.

“The DC6060G has completely transformed our workflow,” said a senior engineer at the company. “Not only does it keep the machine cleaner, but it also ensures consistent output, which is critical for our high-tolerance applications.”

With its full-sealed design, advanced wet-flush system, and proven performance in real-world scenarios, the DC6060G stands out as a reliable choice for graphite machining. It not only protects your investment but also enhances productivity and product quality.

Are you ready to upgrade your graphite processing capabilities? Contact us today to learn more about the DC6060G and how it can benefit your operations.