In the evolving landscape of shoe mold manufacturing, the integration of environmentally friendly new materials has introduced a set of complex challenges. These materials, while promising in terms of sustainability, demand a higher level of precision and adaptability in the manufacturing process. Traditional CNC milling machines, once the mainstay of the industry, are now struggling to keep up with the intricate requirements of processing these advanced materials.

Let's first delve into the pain points brought about by the introduction of eco - friendly materials in shoe mold manufacturing. The unique physical and chemical properties of these materials often result in uneven cutting forces during machining, leading to issues such as surface roughness and dimensional inaccuracies. Moreover, the complex geometries required for modern shoe designs, especially those with curved and irregular surfaces, pose a significant challenge for conventional three - axis CNC machines.

Currently, the mainstream CNC equipment in the market has limitations when it comes to processing complex structural components. Most of these machines lack the flexibility to handle multi - angle and multi - surface machining in a single setup. This not only increases the processing time but also introduces potential errors during the re - positioning of the workpiece. As a result, manufacturers are facing longer production cycles and higher costs, which ultimately affect their competitiveness in the market.

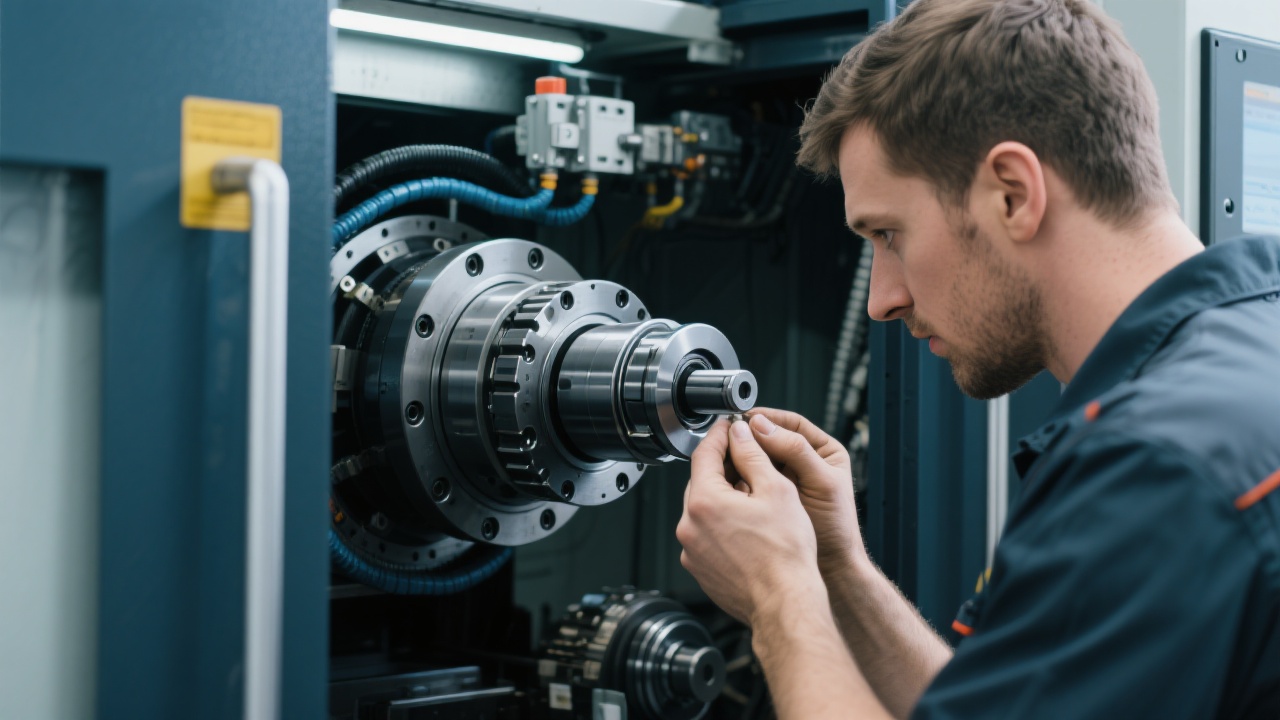

Enter the five - axis shoe last CNC milling machine DC6060A, a revolutionary solution designed to address these challenges. This machine is equipped with a state - of the - art intelligent control system that enables seamless integration from design to manufacturing. The five - axis联动 control technology allows the machine to move along five different axes simultaneously, providing unparalleled flexibility in machining complex geometries. With this technology, the DC6060A can achieve a level of precision that was previously unattainable with traditional machines.

One of the key innovations of the DC6060A is its customized rotary table. This feature allows for continuous and precise rotation of the workpiece, enabling the machine to access all sides of the part without the need for re - clamping. This not only reduces the setup time but also improves the overall accuracy of the machining process. According to our data, the DC6060A can help enterprises improve efficiency by over 30% compared to traditional machines.

Take a well - known brand shoe factory as an example. After implementing the DC6060A, their mass - production cycle was shortened by 30%. This significant reduction in production time allowed them to respond more quickly to market demands and gain a competitive edge.

The synergy between the DC6060A and CAD/CAM software is another area of great potential. By integrating with these software tools, the machine can directly import design models and generate optimized machining programs. This creates a digital design closed - loop, where changes in the design can be quickly translated into manufacturing instructions. As the trend of digitalization in the manufacturing industry continues to grow, this integration will become increasingly important for shoe mold manufacturers.

In addition to its current capabilities, the DC6060A is designed with a focus on continuous iteration. It is built to meet and adapt to the updates of international standards such as ISO and the requirements of emerging materials. This ensures that the machine remains relevant and competitive in the long run, providing a future - proof solution for shoe mold manufacturers.

If you are a decision - maker in the shoe mold manufacturing industry and are looking for a reliable solution to upgrade your production technology, we invite you to download our "White Paper on CNC Machining for Shoe Molds". This comprehensive guide will provide you with in - depth insights into the latest technologies and solutions in the field, helping you make an informed decision for your business.