In the graphite processing industry, machine tools are constantly under the threat of graphite dust and metal chips. These tiny particles can infiltrate into the internal components of the machine, causing wear and tear, and ultimately leading to frequent breakdowns and reduced production efficiency. The Dry Vacuum Graphite Machining Center DC6060G emerges as a revolutionary solution to address these issues.

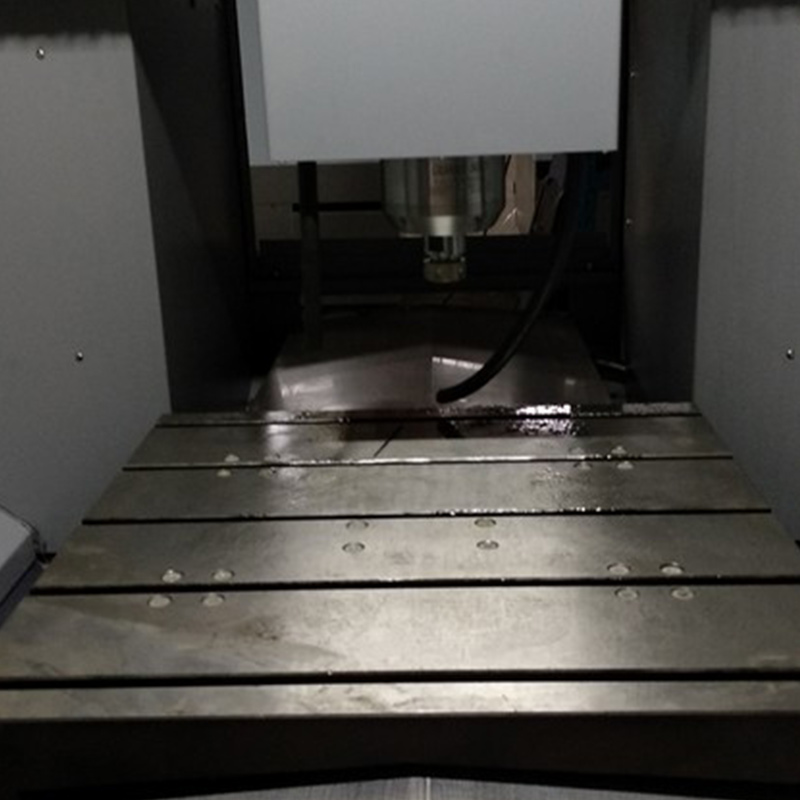

This machining center is designed based on the CNC milling machine DC6060A. Its most prominent feature is the fully - sealed cover design, which is like a solid armor for the machine. This armor - like cover effectively blocks the intrusion of graphite dust and metal chips. According to industry statistics, traditional graphite processing machines without such a sealed design may experience breakdowns every 200 - 300 working hours due to dust and chip intrusion. In contrast, the DC6060G can operate continuously for more than 1000 working hours without major breakdowns caused by these factors. This significant reduction in breakdowns directly translates into a 30% - 40% increase in production efficiency, as less time is wasted on machine maintenance and repair.

The dust - suction device of the DC6060G is another key component of its high - efficiency protection solution. The working principle of this device is based on a powerful vacuum system. During the machining process, it can quickly suck away the graphite dust generated, preventing it from accumulating on the workpiece and the machine surface. A customer feedback survey shows that with the use of the DC6060G's dust - suction device, the surface roughness of the machined graphite products can be controlled within 0.8 - 1.2 micrometers, which is significantly better than the 1.5 - 2.0 micrometers achieved by similar machines without such an advanced dust - suction system. This improvement in surface quality directly ensures the accuracy of the machining and the overall quality of the products.

When compared with other similar graphite machining centers in the market, the DC6060G's protection advantages are obvious. Most competing products only offer partial protection against dust and chips, and their dust - suction systems are less efficient. For example, some similar products can only clean about 60% - 70% of the dust generated during machining, while the DC6060G can achieve a dust - cleaning rate of over 95%. This high - efficiency protection not only extends the service life of the machine but also ensures more stable and accurate machining performance.

One of our customers, a graphite component manufacturing company, was facing frequent machine breakdowns and low - quality product issues before using the DC6060G. After adopting this machining center, they saw a remarkable change. Their production efficiency increased by 35%, and the reject rate of their products decreased from 8% to 2%. This not only saved them a large amount of production costs but also improved their market competitiveness.

In conclusion, the Dry Vacuum Graphite Machining Center DC6060G provides a comprehensive and high - efficiency protection solution for the graphite processing industry. If you are looking for a reliable and efficient graphite machining center, don't miss this opportunity. Contact us now for more information and apply for a free trial!