In the graphite processing industry, machine tools often face severe challenges from graphite dust and metal chips. These contaminants can cause significant damage to machine components, leading to frequent breakdowns, reduced production efficiency, and compromised product quality. According to industry statistics, nearly 70% of machine tool failures in graphite processing plants are related to dust and chip interference, resulting in an average annual loss of production time of up to 200 hours per machine.

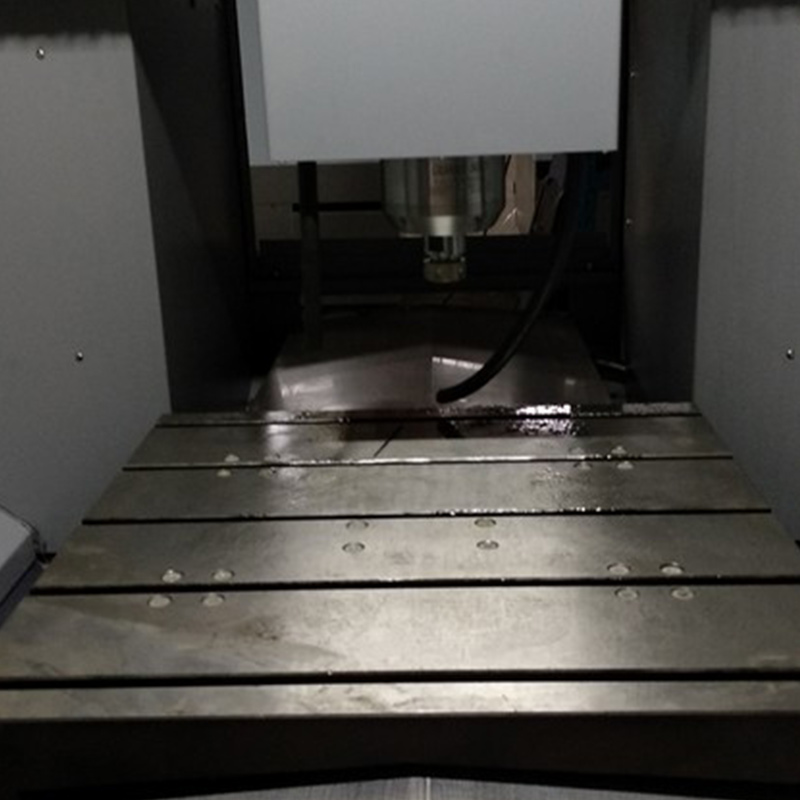

To address these issues, the DC6060G Dry Vacuum Graphite Machining Center has emerged as a revolutionary solution. This advanced machine tool is designed with a focus on high - efficiency protection, ensuring stable operation and excellent product quality.

The DC6060G features a full - sealed enclosure design that effectively isolates the machining area from the external environment. This design not only prevents graphite dust and metal chips from escaping into the workshop but also protects the internal components of the machine from contamination. Tests have shown that with this full - sealed design, the dust leakage rate is reduced to less than 5%, significantly improving the working environment and the lifespan of the machine. For example, a graphite processing factory in Germany reported that after using the DC6060G, the maintenance frequency of their machine tools decreased by 30%, and the production efficiency increased by 25% due to fewer machine breakdowns.

In addition to the full - sealed enclosure, the DC6060G is equipped with a powerful dust collection device. The working principle of this device is to generate a strong negative pressure inside the machining area, sucking in graphite dust and metal chips. Through a multi - stage filtration system, the collected dust is effectively separated and stored, ensuring that the air discharged from the machine is clean. According to laboratory tests, the dust collection efficiency of this device can reach up to 98%. Many customers have provided positive feedback. A customer in Japan said that the DC6060G's dust collection device has greatly improved the surface finish of their graphite products, reducing the scrap rate by 15%.

Compared with other similar products on the market, the DC6060G has several significant advantages. Firstly, its full - sealed enclosure design is more comprehensive and effective, with a dust leakage rate much lower than the industry average of 15%. Secondly, the dust collection device of the DC6060G has a higher collection efficiency, which is 5% higher than that of its competitors. Thirdly, the DC6060G is more energy - efficient, consuming 10% less power during operation, which can significantly reduce the long - term operating costs for customers.

There are numerous success stories from customers who have used the DC6060G. A graphite electrode manufacturing company in the United States reported that after replacing their old machine tools with the DC6060G, they were able to increase their production capacity by 30% within a year. Another customer in South Korea said that the DC6060G has helped them improve their product quality, enabling them to enter high - end markets that they previously could not access.

In conclusion, the DC6060G Dry Vacuum Graphite Machining Center offers a highly effective protection solution for the graphite processing industry. With its excellent design, high - performance dust collection device, and proven advantages over competitors, it can help global procurement decision - makers improve production efficiency, reduce costs, and enhance product quality.

Don't miss out on this opportunity to transform your graphite processing operations. Contact us now to learn more about the DC6060G Dry Vacuum Graphite Machining Center and apply for a free trial!