Graphite machining is a crucial process in various industries, but it comes with a significant challenge: dust and metal shavings pollution. These pollutants not only pose a threat to the health of workers but also can cause damage to the machinery, leading to increased maintenance costs and reduced production efficiency. According to industry statistics, nearly 70% of graphite machining workshops suffer from varying degrees of dust pollution, and the average annual maintenance cost due to dust and metal shavings can reach up to $10,000 per machine.

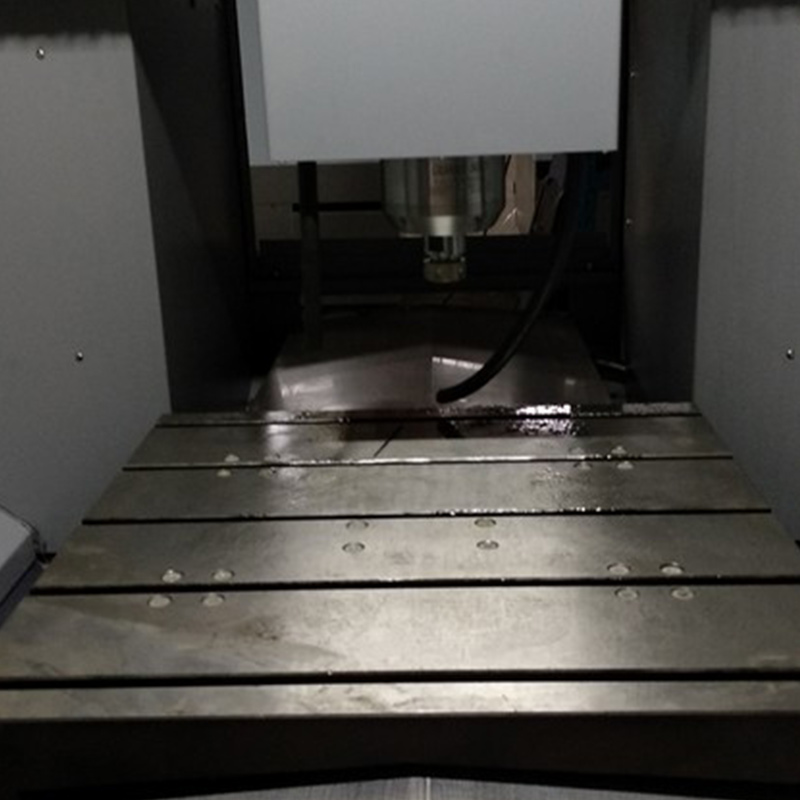

In response to these challenges, the Dry Vacuum Graphite Machining Center DC6060G emerges as a game - changer. This state - of - the - art machine is specifically designed to address the dust and metal shavings issues in graphite machining.

One of the key features of the DC6060G is its all - sealed enclosure design. Unlike ordinary machining centers, which often have open or semi - open structures, the DC6060G's enclosure effectively prevents dust and metal shavings from escaping into the working environment. This design reduces the dust concentration in the workshop by up to 90%, creating a safer and cleaner working environment for the operators.

Complementing the all - sealed enclosure is the high - efficiency dust collection system. The DC6060G is equipped with a powerful vacuum cleaner that can collect dust and metal shavings at a rate of up to 80 cubic meters per minute. In contrast, most ordinary machining centers have a collection rate of only 20 - 30 cubic meters per minute. This means that the DC6060G can quickly and effectively remove dust and metal shavings from the machining area, ensuring the smooth operation of the machine and reducing the frequency of maintenance.

Let's take a look at a real - world example. A graphite machining factory in Germany was facing severe dust and metal shavings problems. The dust in the workshop was so thick that it affected the visibility and the health of the workers. After installing the Dry Vacuum Graphite Machining Center DC6060G, the situation improved significantly. The dust concentration in the workshop dropped from 15 mg/m³ to less than 1 mg/m³, well below the national safety standard. The production efficiency also increased by 30% due to reduced machine downtime for maintenance.

In conclusion, the Dry Vacuum Graphite Machining Center DC6060G offers unparalleled advantages in dust and metal shavings control in the graphite machining industry. Its innovative design and high - performance features make it a reliable choice for graphite machining factories around the world. If you are looking for a solution to your graphite machining pollution problems, don't miss out on the DC6060G.

Contact us today to learn more about how the Dry Vacuum Graphite Machining Center DC6060G can transform your graphite machining operations!