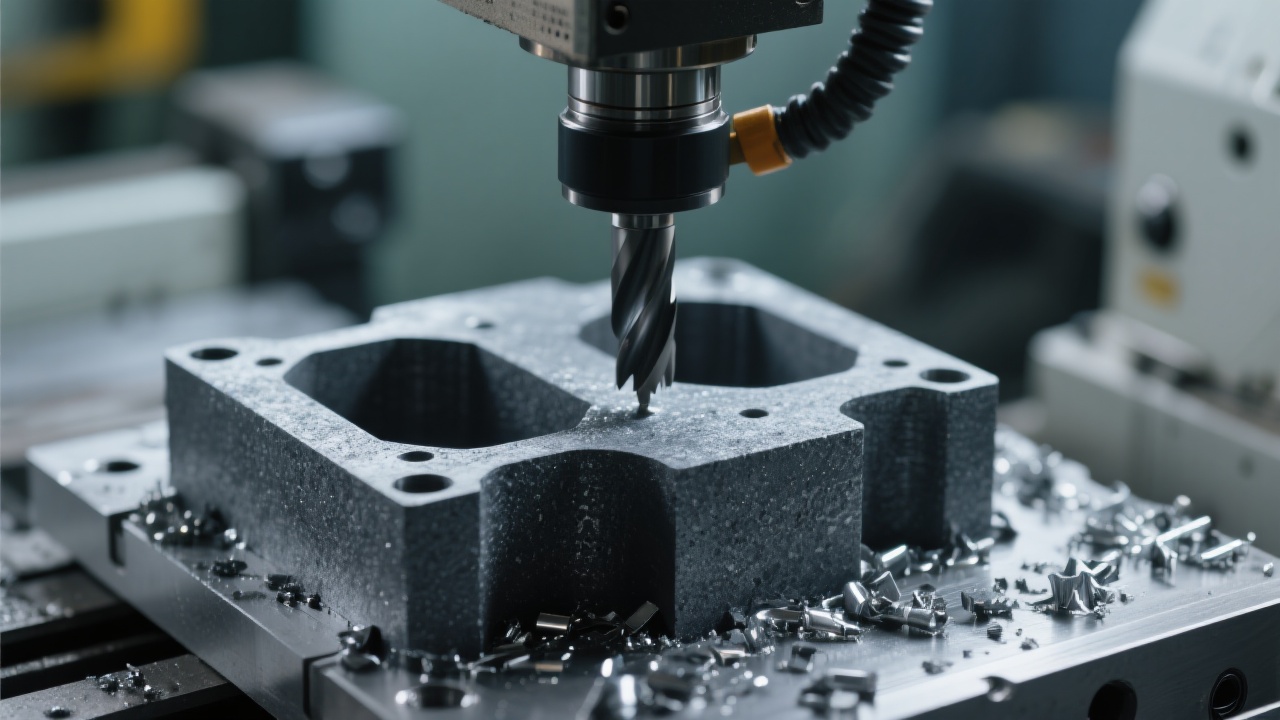

The graphite machining industry continually faces critical challenges stemming from metal shavings and dust infiltration, which significantly increase equipment downtime and maintenance costs. Conventional machine tools, often featuring open structures, succumb rapidly to abrasion and contamination. The DC6060G wet washing graphite machining center revolutionizes this by adopting a fully sealed enclosure design. Incorporating advanced materials, innovative sealing techniques, and optimized airflow cooling systems, this solution strikes a delicate balance between effective dust protection and thermal management, ensuring exceptional operational stability and longevity.

Graphite加工过程常伴随着大量细碎的金属屑与粉尘,这些微粒不仅影响加工精度,更逐渐侵蚀机械关键部件。普通开放式机床结构难以阻挡这些侵害,导致频繁的设备故障和长时间停机。尤其在高洁净度要求的制造场景中,如锂电池电极生产,该类问题直接反映为生产效率与产品质量的下降。

The DC6060G system’s innovation rests on three core technological modules, each meticulously engineered to address the graphite machining environment’s harshness:

| Technical Module | Key Features | Impact |

|---|---|---|

| Material Selection | High-performance polymer composite panels offering corrosion resistance, lightweight durability, and ease of maintenance | Extends enclosure lifetime; reduces part replacement needs by up to 40% |

| Interface Sealing Technology | Dynamic sealing systems integrated with anti-leakage adhesives, ensuring airtight joints across moving parts | Prevents dust ingress effectively, enhancing mean time between failures (MTBF) by approximately 30% |

| Thermal and Airflow Management | Intelligent temperature control with synchronized ventilation paths to maintain stable internal temperature and balanced pressure | Optimizes machine performance; avoids overheating without compromising sealing integrity |

Recent deployments of the DC6060G in leading lithium battery electrode factories reveal compelling improvements. Field data indicates:

An infographic provides a direct comparison between traditional open-structure machining centers and the fully sealed DC6060G, illustrating maintenance frequency and service life improvements.

The traditional open-structure machines often succumb to particulate contamination, leading to:

In contrast, the fully sealed DC6060G’s integrated sealing and thermal management lowers maintenance needs to quarterly cycles or longer, enhances component durability by more than 35%, and maintains optimal processing temperatures with reduced energy consumption.

The engineering approach prioritizes creating a controlled microenvironment through:

This holistic engineering ensures that equipment operates within ideal temperature ranges, significantly reducing thermal stress on sensitive components and preventing premature degradation.

For manufacturers in high-purity graphene and lithium battery domains, implementing such advanced protective architectures translates into quantifiable business value: