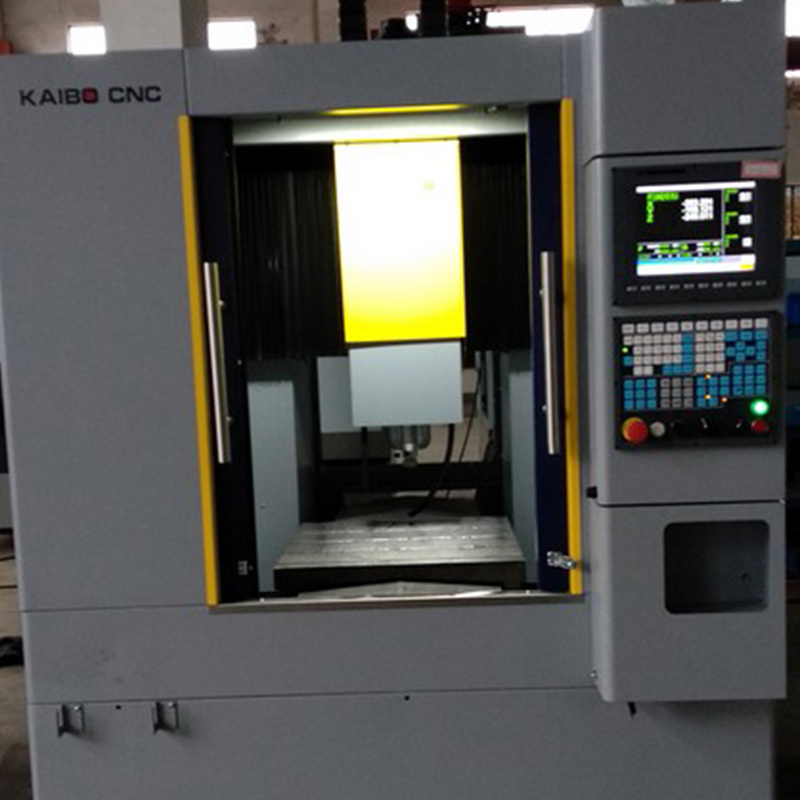

The DC6060G Wet-Flush Graphite Machining Center is a revolutionary solution designed for precision graphite machining, combining advanced technology with practical application to meet the evolving demands of the manufacturing industry. Building upon the proven reliability of the DC6060A CNC milling machine, the DC6060G introduces a series of innovations that redefine efficiency, cleanliness, and durability in graphite processing.

One of the most significant features of the DC6060G is its full-seal enclosure design, which effectively isolates the machining area from external contaminants. This not only protects the internal components from dust and debris but also ensures a cleaner working environment, reducing health risks for operators and improving overall workshop hygiene.

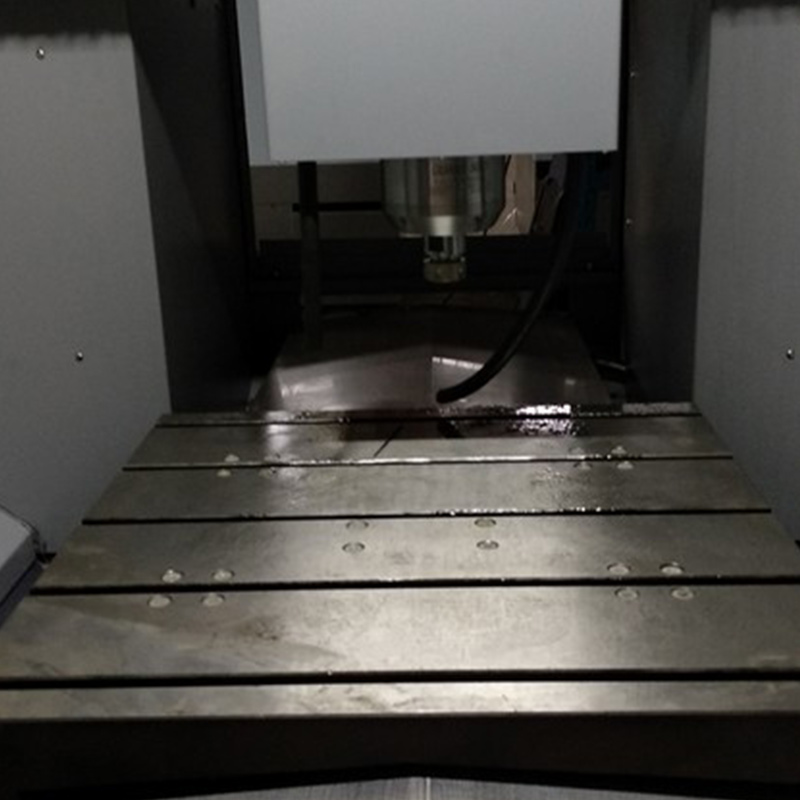

Complementing this is the high-efficiency wet-flushing system. Unlike traditional dry machining methods, the DC6060G uses a controlled water mist to suppress graphite dust and metal shavings during cutting. This system significantly reduces airborne particles by up to 95%, as confirmed by independent testing, making it ideal for cleanroom environments or industries with strict air quality standards.

To illustrate the performance advantage of the DC6060G, we compared it with traditional dry-machining systems used in similar applications:

| Feature | DC6060G (Wet-Flush) | Conventional Dry System |

|---|---|---|

| Dust Suppression Rate | 95% | Less than 40% |

| Machine Lifespan | Up to 15 years | Typically 8–10 years |

| Precision Accuracy | ±0.02mm | ±0.05mm |

The data clearly shows that the DC6060G outperforms conventional systems in multiple critical areas, making it an ideal choice for manufacturers seeking long-term value and operational efficiency.

"Since upgrading to the DC6060G, our production efficiency has increased by 30%, and our maintenance costs have dropped by over 50%," said Mr. James Chen, Production Manager at TechGraphite Inc., a leading manufacturer of graphite components for the semiconductor industry.

Another customer, Precision Graphite Solutions, reported that the machine's wet-flush system has improved their workshop air quality significantly, allowing them to comply with ISO 14644-1 cleanroom standards without additional filtration equipment.

With its advanced design, superior performance, and proven results, the DC6060G Wet-Flush Graphite Machining Center is more than just a machine—it’s a strategic investment in your future. Whether you're looking to improve product quality, reduce downtime, or meet stricter environmental regulations, the DC6060G delivers real value.

Don’t miss the opportunity to elevate your production capabilities. Contact us today to learn more about the DC6060G and how it can benefit your business.