Integrated Design and Installation Guide for Wet Washing Systems in CNC Machine Tools (with Practical Case Study)

12 10,2025

Tutorial Guide

How can wet washing systems effectively address dust pollution in graphite machining? This article thoroughly analyzes the working principles of wet washing systems, focusing on key technologies such as spray methods, water pressure regulation, and filtration-recycling processes. Through a practical case study of the DC6060G CNC machine tool, it demonstrates the system’s deep integration within a high-precision graphite machining environment. A comparative review of dry dust removal versus wet washing highlights the superior benefits of wet systems in equipment protection and operator health, ultimately supporting enhanced production stability and safety.

Integrating Wet Flushing Systems in CNC Machines for Effective Graphite Dust Control

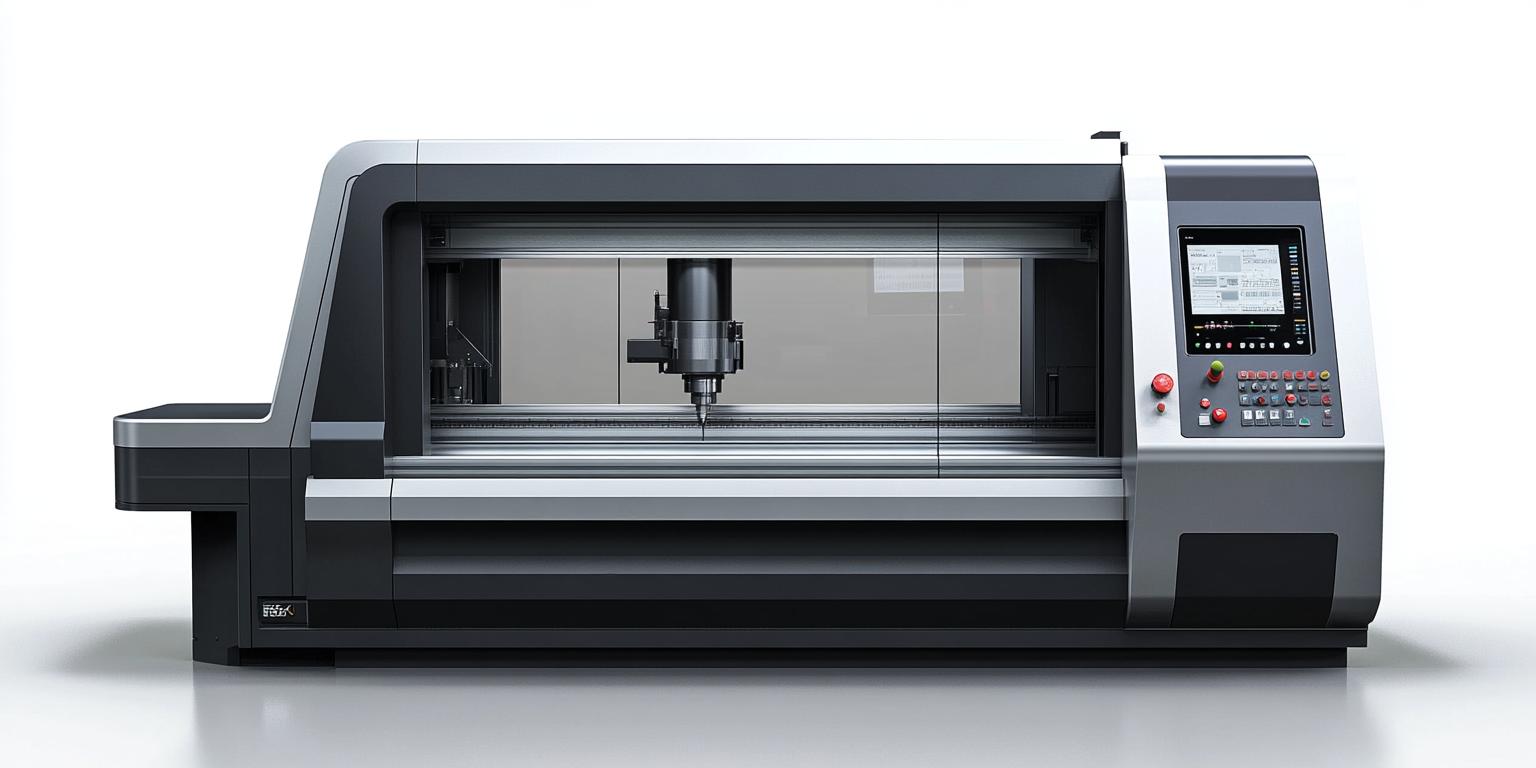

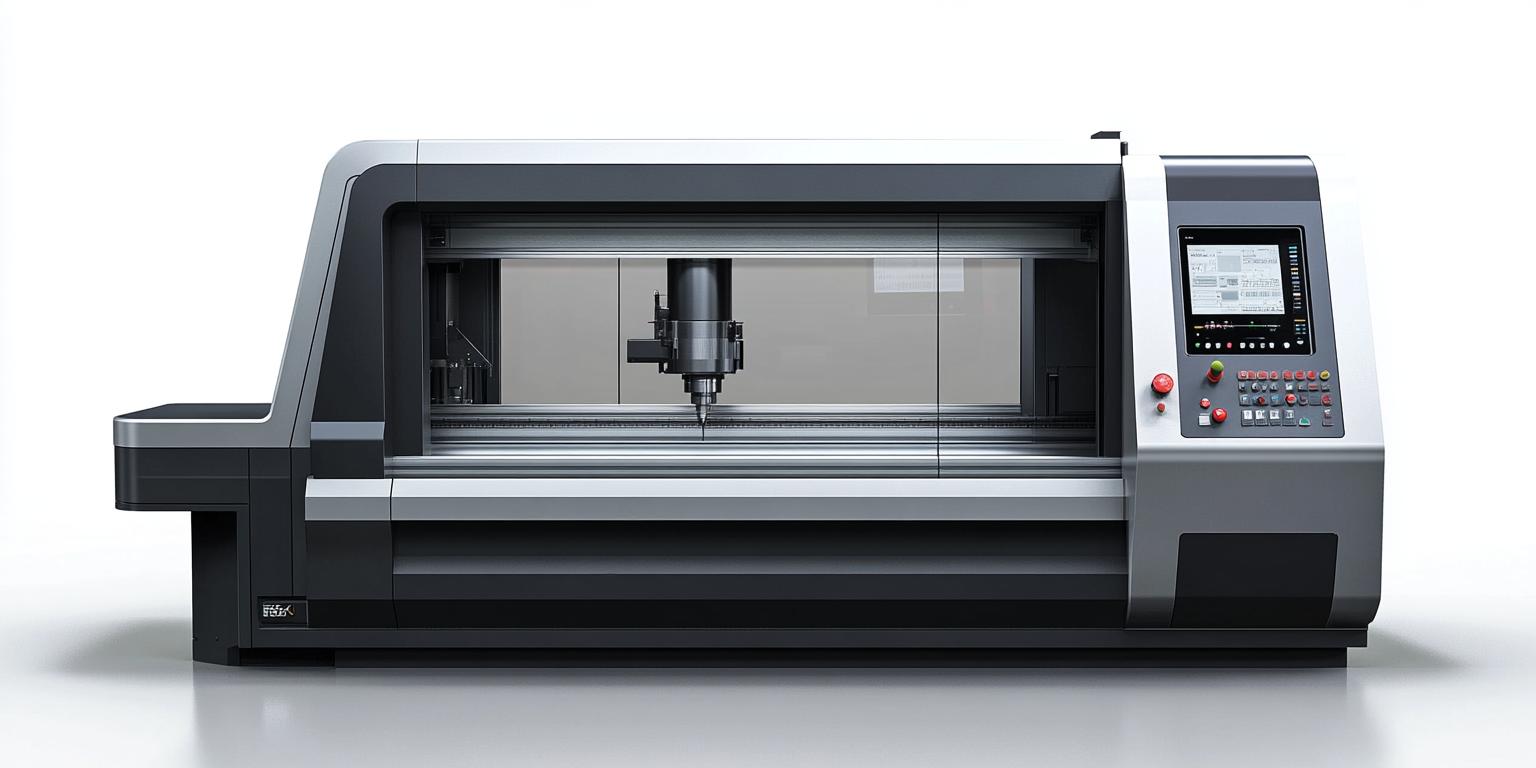

In the precision machining industry, especially in graphite processing, dust generation represents a critical challenge impacting both equipment longevity and worker health. Traditional dry dust extraction methods often fall short in preventing airborne contamination and ensuring machine protection. This guide explores the wet flushing system’s integration with CNC machining centers, focusing on how it innovatively mitigates dust hazards through optimized design and real-world applications, including the DC6060G model.

Understanding Dust Hazards in Graphite Machining

Graphite machining produces fine particulate matter that poses severe risks: respiratory issues to operators, abrasive wear on machine components, and contamination of sensitive processes. Conventional dry dust extraction captures only 65-80% of emitted dust under optimal conditions and often disperses finer particles back into the workspace. This inefficiency can reduce overall production stability by up to 15% due to increased maintenance and downtime.

Core Technologies Behind Wet Flushing Systems

Wet flushing systems effectively address graphite dust by suppressing particulates at the source using water-based removal techniques. The three primary technical pillars include:

- Spray Structure Design: High-efficiency nozzles with adjustable spray angles create comprehensive wetting coverage over the cutting zone, drastically reducing dust liberation.

- Intelligent Water Pressure Regulation: An automated control system dynamically optimizes water flow between 1.2 and 2.5 bars to balance effective flushing while minimizing water consumption.

- Closed-loop Filtration & Recycling: Collected slurry passes through multi-stage filtration units (mesh sizes down to 10 microns) before water is recirculated, promoting sustainability and reducing operational costs by up to 30% compared to single-use systems.

Expert Insight: According to the International Machine Tool Association (IMTA), integrating wet flushing at the machine tool interface is key to achieving sub-micron dust control, a standard progressively required in global manufacturing for environmental compliance.

Real-World Integration: DC6060G CNC Machine Case Study

The DC6060G CNC machining center exemplifies the seamless integration of wet flushing tailored for high-precision graphite applications. By embedding a fully sealed flushing manifold within its enclosure, the system ensures near-zero dust escape and consistent cooling, sustaining machining accuracy within ±0.005 mm.

This tight integration avoids the pitfalls common with retrofit installs, such as leakage and inefficient water use. Operators report a 40% reduction in dust-related maintenance and a 25% improvement in surface finish quality over a production cycle of 600 hours.

Wet Flushing vs. Dry Dust Extraction: Comparative Analysis

| Aspect |

Dry Extraction |

Wet Flushing |

| Dust Capture Efficiency |

65-80% |

>95% |

| Machine Component Wear |

Moderate to High |

Significantly Reduced |

| Worker Health Impact |

Risk of inhalation exposure |

Dramatic reduction in airborne particulates |

| Water Usage |

N/A |

Optimized with recycling |

Practical Maintenance and Troubleshooting Tips

To maintain optimal performance of the wet flushing system:

- Inspect and clean spray nozzles weekly to prevent clogging.

- Monitor water pressure sensors; alerts trigger recalibration if deviations exceed 10% from setpoints.

- Replace filtration cartridges every 500 operational hours or when flow rate decreases by 15%.

- Check seals and gaskets quarterly to ensure full enclosure integrity and dust containment.

Common Fault: Inconsistent spray pressure often signals partial obstruction or pump wear, which can be quickly diagnosed to avoid machining interruptions.

As manufacturing demands escalate for cleaner, safer environments without compromising machining precision, wet flushing systems stand out as an indispensable solution. The DC6060G model’s sophisticated integration offers manufacturers a reliable pathway to elevate both product quality and workplace safety, supported by measurable data and real operational benefits.