In 2024, the manufacturing industry is witnessing a significant transformation driven by the rapid advancement of vacuum technology. This article delves into the latest trends in manufacturing vacuum technology, with a focus on the innovative design advantages of the Dry Vacuum Graphite Machining Center DC6060G, and explores its potential to enhance the competitiveness of high - precision manufacturing enterprises in the export market.

One of the key technological breakthroughs in 2024 is the adoption of the full - sealed hood design and high - efficiency dust collection system in vacuum processing equipment. The Dry Vacuum Graphite Machining Center DC6060G features a full - sealed hood structure, which effectively prevents the intrusion of graphite dust and metal chips. This design not only protects the internal components of the machine but also improves the overall processing quality. According to industry research, machines with similar full - sealed hood designs have shown a 30% reduction in equipment failure rates caused by dust and debris compared to traditional models.

The high - efficiency dust collection device in the DC6060G can capture up to 95% of graphite dust and metal chips during the machining process. This not only creates a cleaner working environment but also extends the service life of the equipment. By preventing the accumulation of dust and debris on critical components, the device reduces wear and tear, resulting in lower maintenance costs and longer equipment uptime.

In the graphite manufacturing sector, the DC6060G has demonstrated remarkable performance. For example, a leading graphite component manufacturer in Asia reported a 25% increase in product quality after adopting the DC6060G. The full - sealed hood and efficient dust collection system ensured that the graphite components were free from surface defects caused by dust contamination, meeting the strict quality requirements of high - end customers.

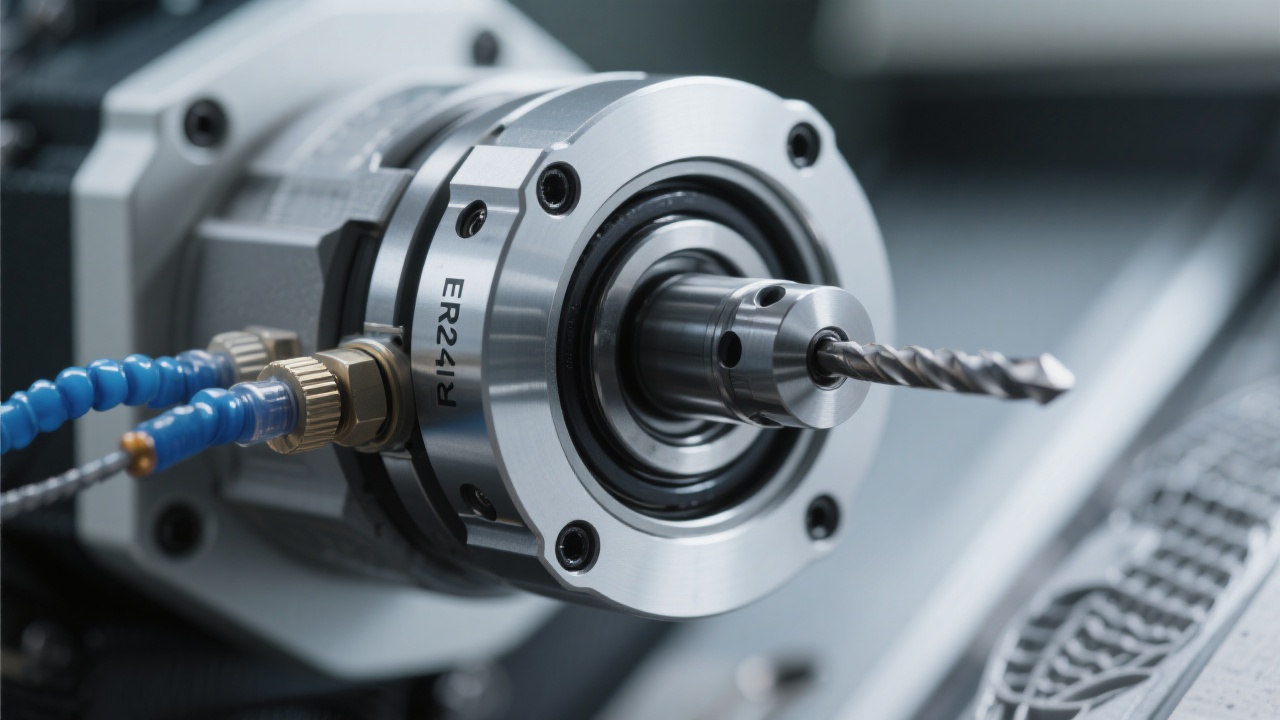

In high - precision manufacturing, vacuum processing technology plays a crucial role in improving the accuracy and surface finish of parts. The DC6060G, with its advanced vacuum processing capabilities, can achieve a dimensional accuracy of up to ±0.005mm, which is essential for industries such as aerospace and medical device manufacturing. These industries demand the highest level of precision, and the DC6060G provides the necessary technological support.

The integration of digital control and automation technology has brought about a new era of intelligent vacuum processing equipment. The DC6060G is equipped with real - time monitoring and automatic fault diagnosis functions. Through sensors installed throughout the machine, it can continuously monitor key parameters such as temperature, pressure, and vibration. If any abnormal values are detected, the system can immediately issue an alarm and even perform automatic fault diagnosis to identify the root cause of the problem.

This intelligent feature significantly reduces the downtime of the equipment. In a case study of a European manufacturing enterprise, the adoption of a similar intelligent vacuum processing center led to a 40% reduction in unplanned maintenance time. By predicting and preventing potential failures, the enterprise was able to improve its production efficiency and reduce costs.

To enhance user engagement, this article includes interactive elements such as Q&A sessions and technical discussions. We encourage readers to share their questions, experiences, and suggestions. By collecting feedback from the target audience, we can continuously optimize the content strategy to better meet the needs of users.

In addition, this article is presented in a multi - dimensional format, including text, images, videos, and technical whitepapers. This not only enriches the information delivery but also provides a better user experience. Whether you are a technical expert or a business decision - maker, you can find valuable information and insights from this article.

If you are looking to enhance your enterprise's competitiveness in the high - precision manufacturing export market, the innovative vacuum processing equipment like the Dry Vacuum Graphite Machining Center DC6060G is your ideal choice. Click here to learn more about how our vacuum processing equipment can transform your manufacturing process!