In the graphite processing industry, dust pollution poses a severe threat to equipment lifespan and production safety. This article delves into how the dry vacuum graphite machining center DC6060G achieves precise dust control through its full-sealed hood design and high-efficiency dust collection system, which not only protects the machine tool's electronic components from corrosion but also helps enterprises transform towards green manufacturing.

Graphite dust is a common by - product in the graphite processing process. The fine particles can easily penetrate into the internal components of the equipment, causing corrosion and damage to electronic elements. According to industry statistics, in graphite processing workshops without effective dust control, the failure rate of equipment can be as high as 40% due to dust - related issues, which seriously affects the stability of production and increases maintenance costs.

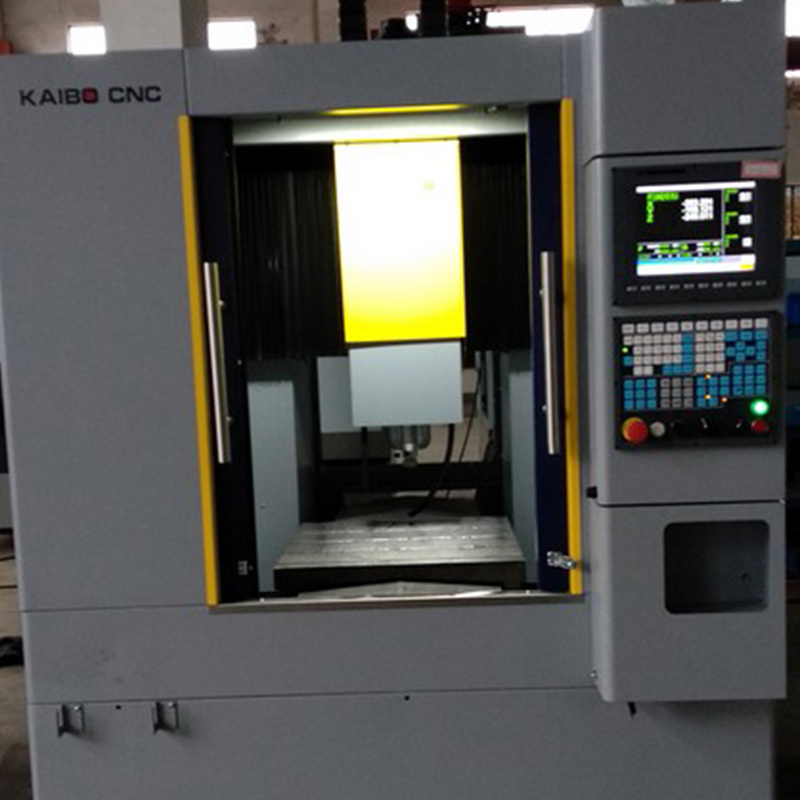

The DC6060G model features an innovative structural design. Its full - sealed hood provides a physical barrier that prevents dust from spreading into the surrounding environment. The hood is made of high - strength materials with excellent sealing performance. At the same time, the efficient dust collection system is closely integrated with the hood. The dust collection device can quickly absorb the generated dust at the source, with an absorption efficiency of up to 95%. This synergy between the full - sealed hood and the dust collection device ensures that the graphite dust is precisely controlled within the machining area.

To ensure the long - term stable operation of the DC6060G, a comprehensive daily maintenance process is essential. Firstly, the sealing performance of the full - sealed hood should be checked at least once a week. Any signs of wear or damage should be repaired immediately. Secondly, the dust collection module needs to be cleaned every two weeks to maintain its high - efficiency operation. In addition, the workshop environment should be well - managed, with a relative humidity of 40% - 60% and a temperature of 20 - 25°C to prevent the agglomeration of graphite dust.

"Since using the DC6060G, our equipment failure rate has dropped significantly. The lifespan of our machines has been extended by more than 30%. This not only saves us a lot of maintenance costs but also improves our production efficiency." - A European graphite processing enterprise

In the context of the national "dual carbon" goal, the dust control technology of the DC6060G is of great significance for enterprises. By reducing dust emissions, enterprises can achieve green manufacturing, which is in line with the global trend of environmental protection. Moreover, this technology can help enterprises meet international environmental regulations, providing export compliance guarantees. It also enhances the enterprise's international competitiveness by improving production efficiency and product quality.

Ready to take your graphite processing to the next level with green manufacturing? Click here to learn more about the DC6060G!