In the graphite machining industry, machine tools often face severe challenges from graphite dust and metal chips. These fine particles can infiltrate machine components, causing abrasion, corrosion, and even system failures. According to industry research, nearly 70% of machine tool malfunctions in graphite machining environments are related to dust and chip contamination. This not only leads to frequent maintenance and replacement of parts but also significantly reduces production efficiency, increasing overall production costs.

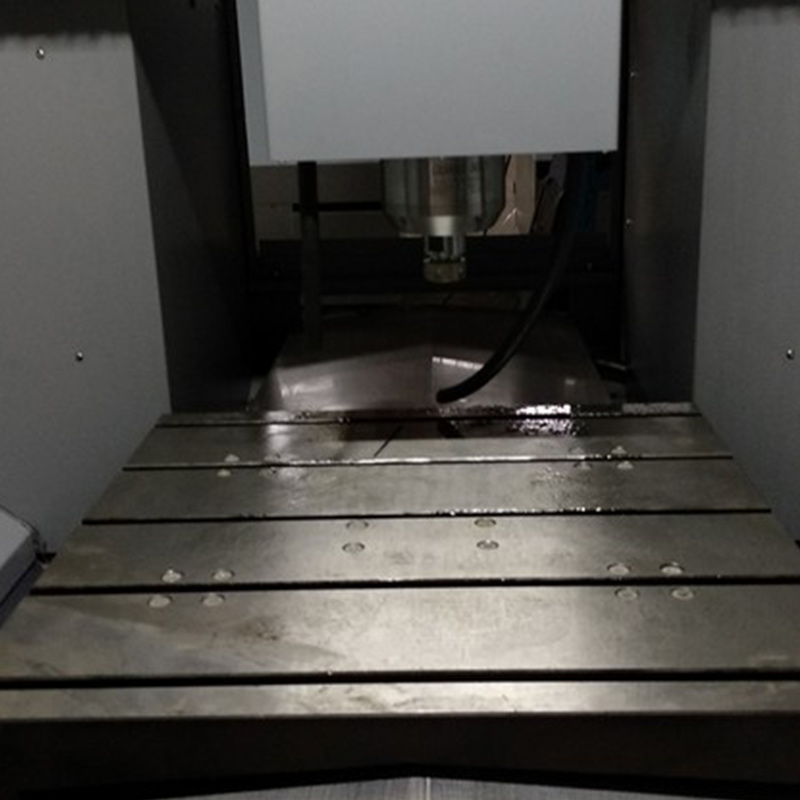

To address these issues, [Company Name] has developed the DC6060G dry vacuum graphite machining center. This innovative product is designed based on the numerical control milling machine DC6060A, with a focus on enhancing protection and dust removal capabilities.

The DC6060G features a full-sealed enclosure design, which effectively prevents graphite dust and metal chips from entering the machine. This design is not only beneficial for the internal components of the machine but also for the working environment. By isolating the machining area, the risk of dust exposure to operators is greatly reduced, improving workplace safety.

In practical applications, the full-sealed enclosure design has been proven to significantly improve production efficiency. A customer in the automotive parts manufacturing industry reported that after using the DC6060G, the machine's maintenance frequency decreased by 50%, and the production efficiency increased by 30%. This is mainly because the machine can operate continuously without being affected by dust and chips, reducing downtime for maintenance and cleaning.

The DC6060G is equipped with a high-performance dust collection device. Its working principle is based on the principle of vacuum suction. During the machining process, the dust collection device generates a strong suction force, quickly sucking the graphite dust and metal chips into the dust collection box. This not only keeps the machining area clean but also reduces the risk of dust explosion.

According to customer feedback, the dust collection efficiency of the DC6060G can reach up to 95%. A customer in the electronics manufacturing industry mentioned that the air quality in the workshop has been significantly improved after using the DC6060G, and the health of operators has also been better protected.

Compared with similar products in the market, the DC6060G has obvious advantages. In terms of protection performance, most similar products only have partial enclosures, which cannot effectively prevent dust and chips from entering the machine. In contrast, the full-sealed enclosure design of the DC6060G provides comprehensive protection.

In terms of dust collection efficiency, the dust collection device of the DC6060G can achieve a higher suction force and collection rate. Some similar products may have a dust collection efficiency of only about 80%, while the DC6060G can reach 95%.

Here are some success stories from customers who have used the DC6060G:

If you are looking for a high-performance graphite machining center that can effectively solve the problems of dust and chip contamination, the DC6060G is your ideal choice. Don't miss this opportunity to improve your production efficiency and product quality.

Contact us today to learn more about the DC6060G and apply for a free trial!