In the graphite processing industry, traditional machine tools often face severe dust pollution problems. Graphite dust is not only harmful to the health of operators but also has a significant negative impact on the service life of machine tools. According to relevant research, in a common graphite processing workshop without effective dust - control measures, the failure rate of machine tools can be as high as 30% due to dust intrusion, and the annual maintenance cost of machine tools can increase by about 25%. These problems seriously affect the production efficiency and economic benefits of enterprises.

The wet graphite machining center DC6060G is based on the numerical control milling machine DC6060A for optimized design. The designers carefully analyzed the structural characteristics and performance requirements of the original model, and made a series of targeted improvements. For example, in terms of the mechanical structure, the rigidity of the machine tool has been increased by 20%, which can better withstand the cutting force during high - speed machining of graphite, ensuring the stability of machining accuracy. At the same time, the movement accuracy of the machine tool has been improved, and the positioning accuracy can reach ± 0.005mm, which can meet the high - precision machining requirements of graphite products.

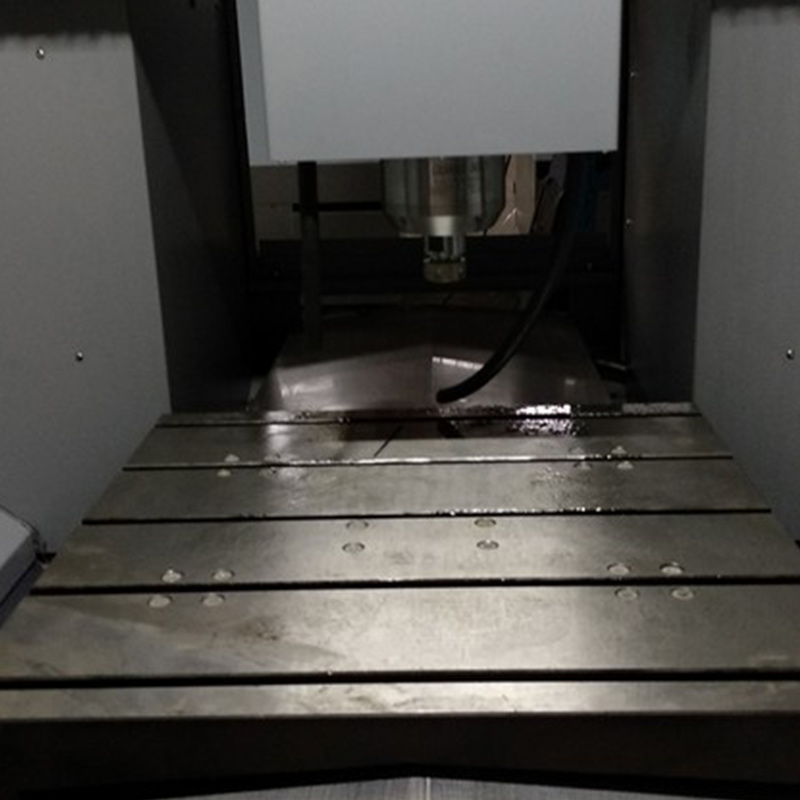

The full - sealed enclosure of the DC6060G is one of its core innovations. This enclosure completely isolates the machining area from the external environment, effectively preventing graphite dust from escaping into the workshop. Made of high - strength and transparent materials, it allows operators to clearly observe the machining process while ensuring sealing. In addition, the full - sealed enclosure also has good sound - insulation performance, which can reduce the noise generated during the operation of the machine tool by about 15 decibels, creating a more comfortable working environment for operators.

The wet - flush system is another highlight of the DC6060G. During the machining process, a certain pressure of water is sprayed into the machining area through nozzles. This water can not only effectively wash away graphite dust but also cool the cutting tool, reducing the wear of the cutting tool. The wet - flush system can reduce the temperature of the cutting tool by about 150°C during high - speed machining, which can increase the service life of the cutting tool by about 40%. At the same time, the flushed graphite dust is collected and treated together with water, which greatly reduces the dust content in the air of the workshop. Tests have shown that in a workshop using the DC6060G, the dust concentration can be reduced to less than 10mg/m³, far lower than the national standard.

Many customers have already experienced the excellent performance of the DC6060G. For example, a well - known graphite product manufacturing enterprise in Europe introduced several DC6060G machining centers. After using them for half a year, the failure rate of the machine tools decreased from 30% to less than 5%, and the annual maintenance cost decreased by about 30%. The production efficiency has also been significantly improved, and the output of graphite products has increased by about 20%. These real - world cases fully demonstrate the reliability and high efficiency of the DC6060G in actual production.

The wet graphite machining center DC6060G effectively solves the dust pollution problem in traditional graphite machining through its innovative design, improves the machining efficiency and service life of machine tools, and helps customers achieve efficient, clean, and sustainable production goals. If you are also troubled by the problems in graphite machining, why not choose the DC6060G? Click here to learn more about the product details and take the first step towards high - quality graphite processing!