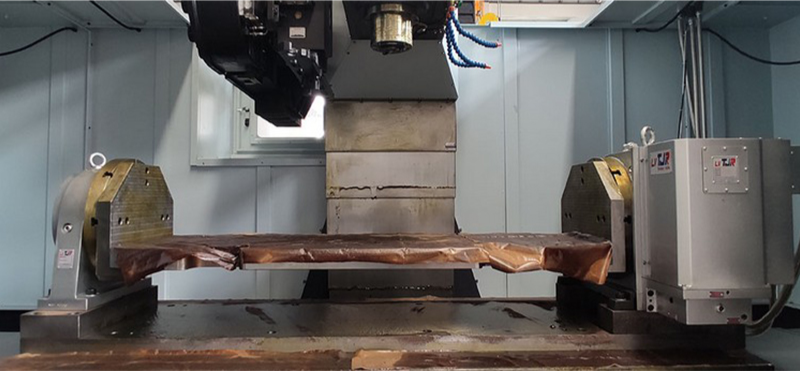

In the field of graphite processing, dust pollution has always been a significant challenge. It not only affects the service life of equipment but also poses a threat to the safety of operators. This article focuses on the effective control methods of dust pollution in graphite processing and introduces a high - efficiency CNC machine tool solution with an integrated wet flushing system.

The wet flushing system mainly consists of three key parts: the spray method design, water pressure adjustment mechanism, and filtration and recovery process. In the spray method design, different spray patterns are used according to the characteristics of graphite processing. For example, a fine - mist spray can effectively capture small dust particles, while a large - flow spray is suitable for quickly removing large dust accumulations. The water pressure adjustment mechanism is crucial for ensuring the effectiveness of the wet flushing. Generally, a water pressure of 2 - 5 MPa can meet most graphite processing requirements. By adjusting the water pressure, the system can adapt to different processing scenarios.

The filtration and recovery process is an important part of the wet flushing system. After the water captures the dust, it enters the filtration system. Through a multi - stage filtration process, the dust is separated from the water, and the filtered water can be recycled. This not only reduces water consumption but also minimizes environmental pollution. For example, in a large - scale graphite processing factory, the filtration and recovery system can recycle up to 80% of the water used in the wet flushing process.

Dry dust removal and wet flushing are two common methods for dust control in graphite processing. Dry dust removal systems, such as bag - type dust collectors, are relatively simple in structure and have a certain dust - removal effect. However, they are not very effective in capturing fine dust particles, and the dust accumulated in the system can easily cause corrosion to the equipment. In addition, dry dust removal systems have a higher risk of fire and explosion in the graphite processing environment.

In contrast, the wet flushing system has significant advantages. It can effectively capture fine dust particles, prevent dust from corroding the equipment, and reduce the risk of fire and explosion. According to relevant research, the dust - removal efficiency of the wet flushing system can reach over 95%, while the dry dust removal system is only about 80%.

| Dust Removal Method | Dust - Removal Efficiency | Equipment Corrosion Risk | Fire and Explosion Risk |

|---|---|---|---|

| Dry Dust Removal | About 80% | High | High |

| Wet Flushing | Over 95% | Low | Low |

In practical applications, the wet flushing system has been widely used in high - precision graphite processing environments. For example, in a certain graphite electrode manufacturing plant, after installing the wet flushing system, the service life of the CNC machine tool has been extended by 30%, and the frequency of equipment failures has been reduced by 40%. This shows that the wet flushing system can effectively improve the stability and safety of equipment operation.

To ensure the normal operation of the wet flushing system, regular maintenance is essential. This includes checking the spray nozzles for blockage, inspecting the water pressure adjustment mechanism, and cleaning the filtration system. In addition, the article also provides practical guidance on troubleshooting, such as how to deal with water leakage and low water pressure problems.

In conclusion, the wet flushing system integrated in the CNC machine tool is an effective solution for dust control in graphite processing. It not only has significant technical advantages but also has high practical value. If you are looking for a reliable solution for graphite processing dust control, click here to learn more about our integrated wet flushing system for CNC machine tools.