In the specialized field of graphite machining, airborne graphite dust poses significant challenges to manufacturing equipment. This dust not only accelerates wear and tear on sensitive machine components but also creates potential safety hazards and compromises machining precision. Understanding the formation, physical and chemical properties of graphite dust, alongside advanced mitigation technologies, is paramount for industrial operations aiming to optimize equipment longevity and reduce operational costs.

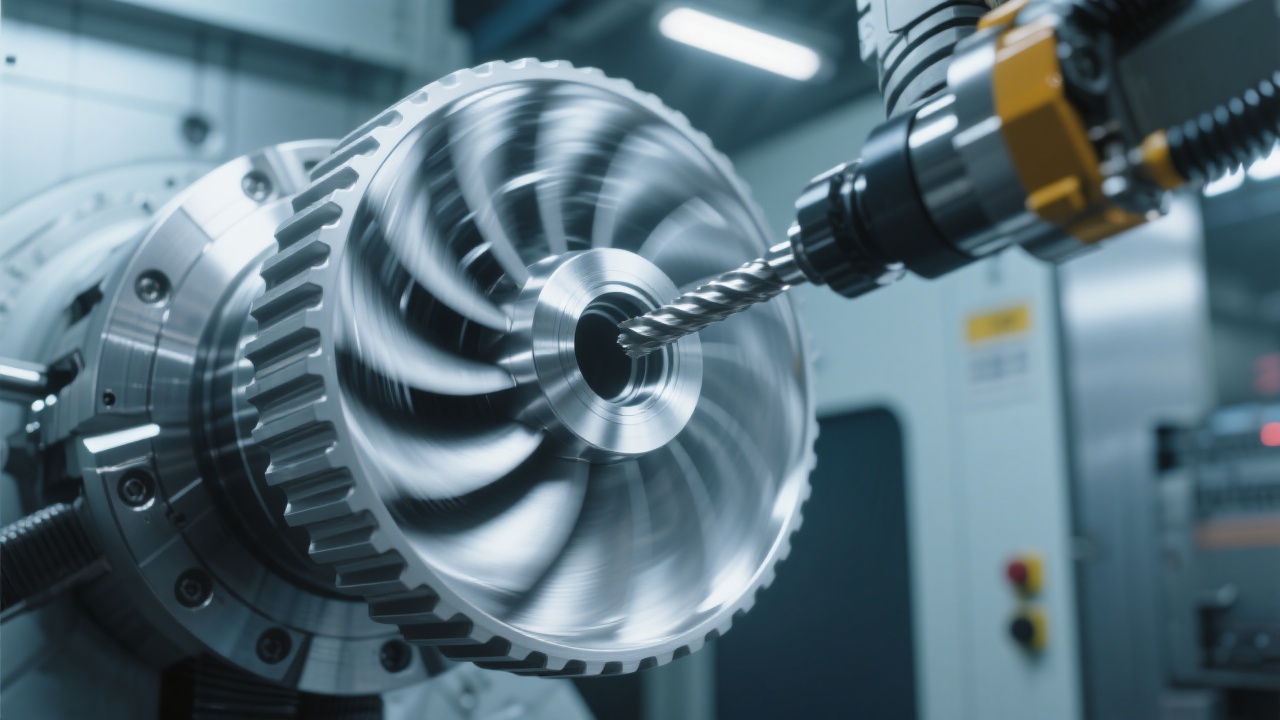

Graphite machining inherently generates fine particulate matter primarily through mechanical abrasion during shaping, cutting, and drilling processes. These particles typically range between 0.1 to 10 micrometers in diameter—classified as respirable dust—and exhibit strong electrical conductivity and chemical inertness. However, when these particles become airborne, their interaction with moisture and lubricants in machine environments can trigger electrochemical corrosion, affecting nearby components adversely.

The critical components at risk from graphite dust include electronic circuits, linear guide rails, and ball screws. Dust deposition leads to abrasive wear and contaminant accumulation, which disrupts lubrication films essential for smooth motion. Furthermore, microscopic graphite particles conduct electricity and may cause unexpected short circuits in electronic assemblies. Chemical interactions due to dust-induced corrosion reduce component accuracy, resulting in decreased machining precision—industry reports indicate a potential accuracy drop of up to 15% within 6 months of uncontrolled exposure.

Traditional CNC machines with semi-open or open frameworks fail to adequately prevent graphite dust ingress, resulting in frequent maintenance and higher downtime. Open structures allow dust to settle extensively on vulnerable parts, increasing cleaning frequency and operational costs. According to a benchmark study, equipment employing conventional setups experienced a 30% higher maintenance frequency compared to fully enclosed systems.

The dry vacuum graphite machining center model DC6060G exemplifies a breakthrough in powder control technology. It features a full-sealed enclosure combined with a high-efficiency vacuum dust extraction system. This synergy achieves near 100% containment of airborne graphite particles at the source. The full-sealed hood design effectively isolates critical components from dust exposure, while the vacuum system continuously evacuates generated dust, reducing particulate accumulation on guides and screws.

Operational data from industrial end-users illustrate the DC6060G’s efficacy: a 40% reduction in unexpected equipment stoppages and a 25% decrease in overall maintenance time within the first year of deployment. These improvements translate directly into cost savings and enhanced production stability, reinforcing the value of integrating advanced dust control solutions.

| Maintenance Task | Recommended Frequency | Impact on Equipment Health |

|---|---|---|

| Sealing Integrity Inspection | Monthly | Prevents dust infiltration, extends component life by 15-20% |

| Vacuum Filter Cleaning and Replacement | Bi-weekly cleaning; quarterly filter replacement | Ensures sustained dust extraction efficiency above 95% |

| Workshop Ambient Air Monitoring | Quarterly | Minimizes secondary dust contamination risk |

Consistent adherence to these maintenance protocols helps maintain high processing accuracy and reduce corrective downtime. Feedback from multiple industries corroborates that disciplined cleaning and sealing inspections reduce equipment wear rates by up to 25%, subsequently lowering total cost of ownership.

Beyond equipment protection, controlling graphite dust aligns with environmental compliance and workplace safety mandates. The DC6060G’s design significantly minimizes particulate emissions, contributing to cleaner production environments. As industries adopt greener manufacturing practices, technologies offering dust containment and reduced lubricant waste showcase competitive advantages.

Innovative solutions like DC6060G empower enterprises to not only extend their machinery lifespan but also enhance product precision and operational efficiency, while keeping environmental impact in check.