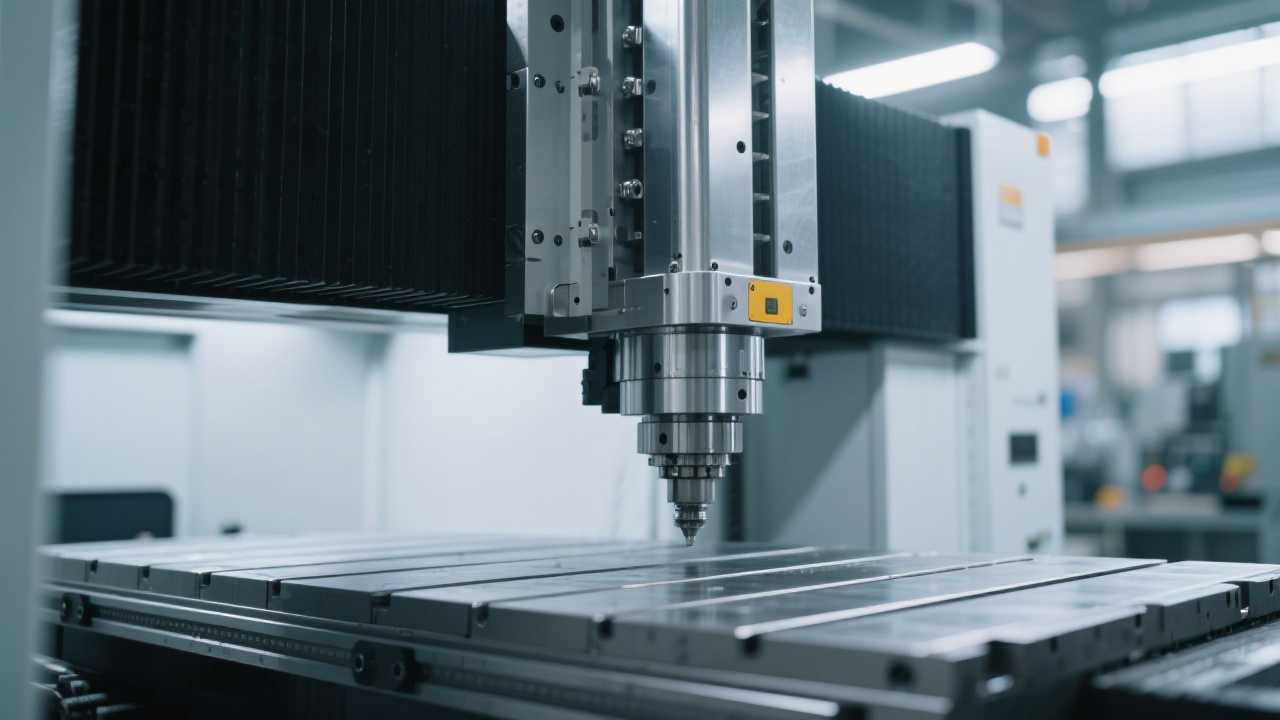

In the realm of graphite processing, the issue of dust and metal shavings infiltrating machine tools has long been a persistent challenge. This problem not only leads to frequent malfunctions but also significantly drives up maintenance costs. In this article, we will delve into the three engineering logics behind the fully sealed enclosure design of the wet - flushing graphite machining center DC6060G, which effectively addresses these issues.

Graphite processing generates a large amount of fine dust and metal shavings. Traditional machine tools are highly susceptible to dust pollution for several reasons. Firstly, their open or semi - open structures provide easy access for dust and shavings to enter the internal components of the machine. Secondly, the lack of effective sealing mechanisms at interfaces and joints allows these contaminants to penetrate, causing abrasion and damage to critical parts such as bearings, guides, and spindles. As a result, the Mean Time Between Failures (MTBF) of traditional machines is relatively short, often requiring frequent maintenance and part replacements.

The choice of polymer composite materials for the fully sealed enclosure is crucial. These materials are selected for their high strength, wear - resistance, and excellent dust - proof properties. They can effectively prevent dust and shavings from adhering to the surface of the enclosure and entering the machine. For example, some advanced polymer composites have a smooth surface that reduces the chance of dust accumulation, and they also have good chemical stability, which can resist corrosion from the coolant used in the wet - flushing process.

The dynamic sealing interface technology is another key aspect of the design. At the interfaces where moving parts meet the enclosure, such as the spindle and the worktable, special sealing processes are employed. These processes ensure that even during the dynamic operation of the machine, there are no gaps for dust and shavings to enter. For instance, the use of high - precision rubber seals and labyrinth - like sealing structures can effectively block the intrusion of contaminants while allowing smooth movement of the parts.

While ensuring dust and shavings prevention, the design also takes into account the heat dissipation requirements of the machine. A balanced system for heat dissipation and ventilation is implemented. This system uses a combination of fans, heat exchangers, and ventilation ducts to maintain an optimal operating temperature inside the machine. It can dissipate the heat generated by the spindle, motors, and other components during operation, preventing overheating while keeping the internal environment clean.

In the lithium - ion battery electrode production industry, the precision and cleanliness of the machining process are of utmost importance. A company that adopted the wet - flushing graphite machining center DC6060G with the fully sealed enclosure design has witnessed significant improvements. Before using this machine, their traditional machines had an MTBF of about 200 hours, and the maintenance frequency was once every 10 days. After switching to the new machine, the MTBF increased to over 500 hours, and the maintenance frequency decreased to once every 30 days. This not only reduced the downtime of the production line but also saved a large amount of maintenance costs.

| Indicator | Before Sealed Design | After Sealed Design |

|---|---|---|

| MTBF (hours) | 200 | Over 500 |

| Maintenance Frequency | Once every 10 days | Once every 30 days |

The fully sealed enclosure design is of great significance in industries such as aerospace composite materials and new - energy batteries. In the aerospace industry, the high - precision machining of composite materials requires a clean and stable environment. The dust - proof and shavings - proof design can ensure the accuracy and quality of the machined parts. In the new - energy battery industry, the production of high - quality battery electrodes also depends on the high - precision and clean machining process provided by this kind of machine.

If you are looking for a high - precision and dust - proof graphite processing solution, don't miss out on our High - Cleanliness Machining Center Protection White Paper. Download it now to get more in - depth technical information and make a wise decision for your business!