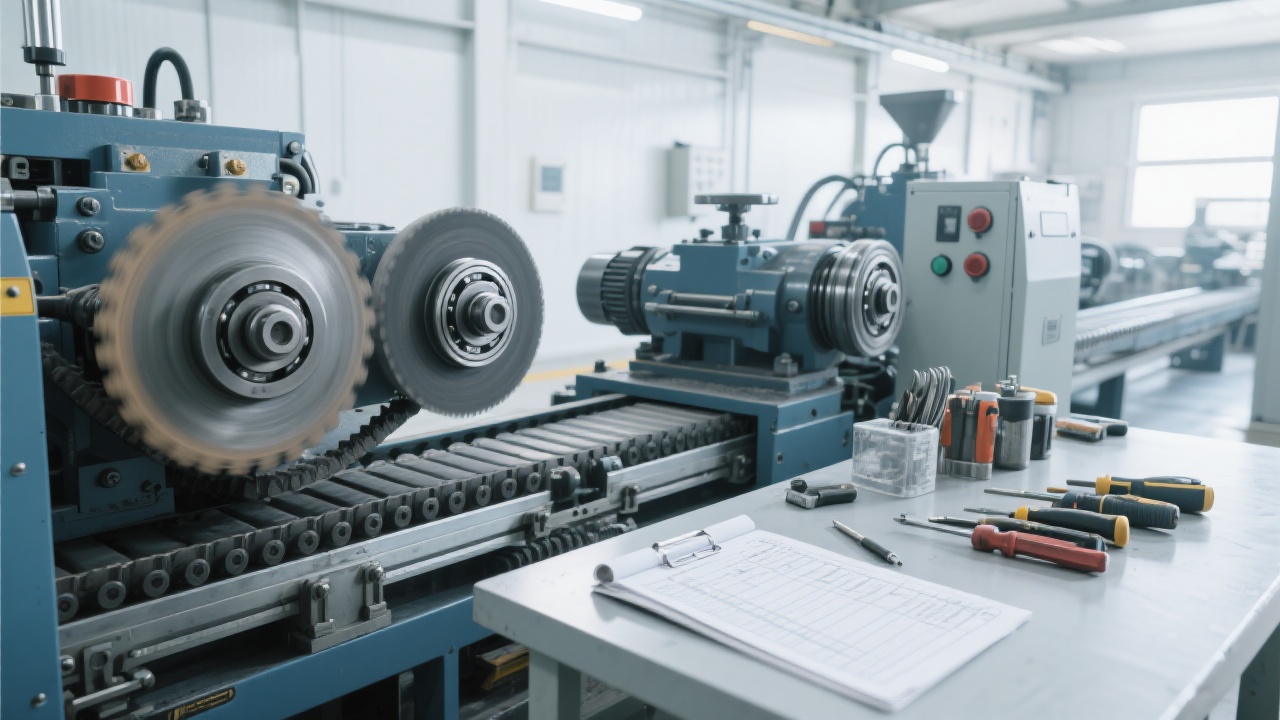

Graphite dust is a common by - product in graphite processing. It can cause significant damage to graphite processing equipment. When graphite dust accumulates on electronic components, it can lead to corrosion. The conductive nature of graphite dust may cause short - circuits in electronic circuits, increasing the risk of equipment failure. Moreover, graphite dust can also adhere to the surface of machine parts, affecting the smooth movement of parts and reducing the machining accuracy. For example, a small amount of graphite dust on the guide rails can cause uneven wear, which directly impacts the precision of workpiece machining.

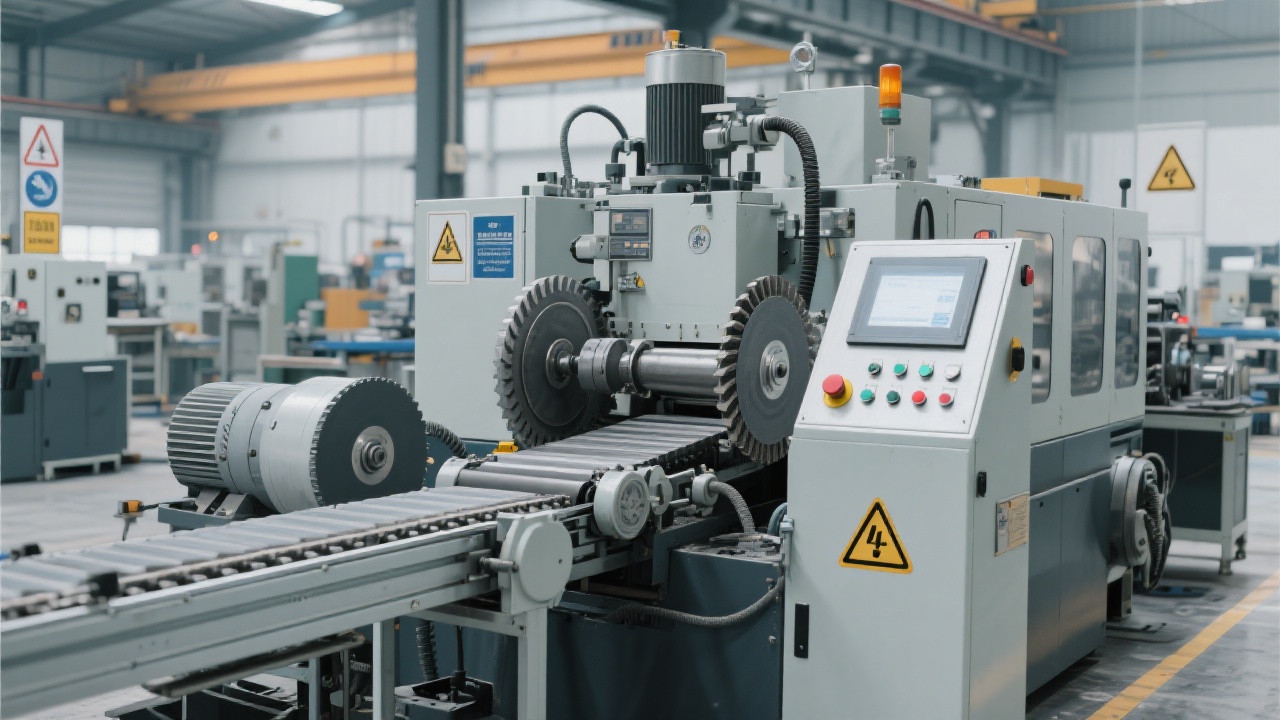

The fully sealed enclosure of the dry vacuum graphite machining center DC6060G is designed to isolate graphite dust effectively. Its design principle is based on the concept of creating a closed space to prevent dust from escaping. By using high - quality sealing materials and a reasonable structure, the fully sealed enclosure can achieve dust isolation and environmental purification. This not only protects the equipment inside but also improves the overall air quality in the workshop. For instance, it can reduce the concentration of graphite dust in the air by up to 90%, creating a healthier working environment for operators.

The dust collection device is a crucial part of graphite processing equipment. Its working process starts with the suction of graphite dust by the fan into the dust collection system. Then, the dust is filtered through the filter element, and clean air is discharged. For daily maintenance, you need to pay attention to several key points. First, replace the filter element regularly. A clogged filter element can reduce the dust collection efficiency. It is recommended to replace the filter element every 3 - 6 months depending on the usage frequency. Second, clean the pipes to prevent dust blockage. You should check and clean the pipes at least once a month. Third, inspect the fan to ensure its normal operation. Check the fan blades for damage and the motor for overheating every 2 - 3 months.

To ensure the long - term leak - free operation of the equipment, it is necessary to detect the sealing performance regularly. The detection standard should meet the requirements of relevant industry regulations. For example, the leakage rate should be less than 1%. The frequency of detection should be at least once a quarter. By regularly detecting the sealing performance, you can identify potential problems in time and take corrective measures, which can significantly reduce the risk of dust leakage and protect the equipment and the working environment.

In addition to equipment maintenance, environmental hygiene management is also essential. You can use cleaning tools such as vacuum cleaners to clean the workshop floor and equipment surfaces regularly. At the same time, establish a waste management system to properly handle graphite dust waste. By coordinating equipment maintenance and environmental hygiene management, you can improve the overall cleanliness of the workshop, which is beneficial to the long - term operation of the equipment and the health of operators.

A new energy enterprise applied the above - mentioned maintenance methods to its graphite processing equipment. After implementation, the equipment failure rate decreased by 40%. This shows that by following a systematic maintenance guide, enterprises can effectively solve common pain points, reduce equipment downtime costs, improve equipment stability, and ensure high - precision machining. The data clearly demonstrates the effectiveness of these maintenance measures in the real - world industrial environment.

Are you looking to enhance the performance and lifespan of your graphite processing equipment? Click here to learn more about our comprehensive graphite processing equipment maintenance solutions!