Key Insight: Dust contamination from graphite machining is a primary factor affecting CNC machine tool accuracy and operational longevity. Implementing industry-leading full-seal designs combined with advanced vacuum dust extraction delivers superior protection and maintenance efficiency.

Graphite dust, due to its fine particulate size and abrasive nature, poses a significant threat to both electronic components and mechanical parts within CNC machine tools. The corrosive behavior accelerates actuator wear, degrades sensor precision, and contaminates lubrication systems, ultimately leading to unexpected downtime and costly repairs.

Studies indicate that unmitigated graphite dust exposure can reduce machine lifespan by up to 30%, with maintenance costs increasing by approximately 25%. Therefore, effective dust control is not just a safety measure but a strategic approach to maximizing production stability and reducing total cost of ownership (TCO).

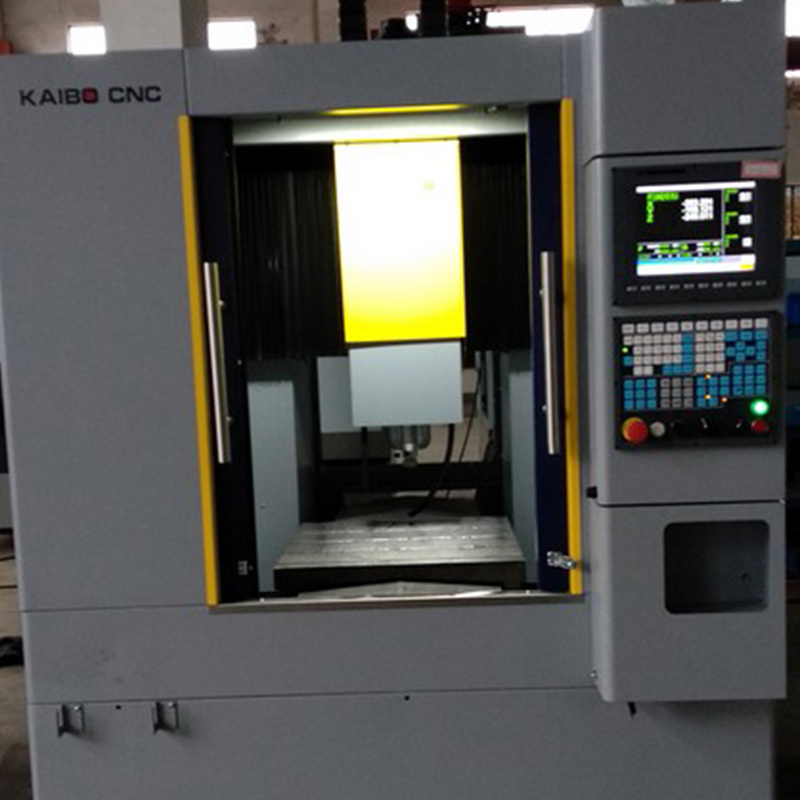

The DC6060G machining center integrates an industry-leading full-seal enclosure, specifically engineered to isolate the machine’s sensitive internal components from graphite dust intrusion. This design relies on multiple layers of sealing around the spindle, tool changer, and control cabinets, minimizing dust ingress by over 95% compared to conventional open-structure machines.

This full sealing technology not only safeguards mechanical precision but also significantly reduces the frequency of dust-related shutdowns, enhancing production uptime by an estimated 15-20%. Additionally, operators benefit from a cleaner and safer working environment conducive to green intelligent manufacturing initiatives.

Complementing the full-seal structure, DC6060G employs a dry vacuum dust extraction system featuring a high-efficiency multi-stage filtration unit. This system actively captures graphite particles right at the source, using a strategically positioned nozzle assembly and variable-speed vacuum pumps that adjust extraction rates based on machining load.

Compared to traditional hood-and-broom or wet scrubber methods, this vacuum system reduces airborne particulate matter (PM2.5) concentrations by up to 90%. It also eliminates water contamination risks common in wet systems, thereby reducing maintenance workload and promoting continuous operation without environmental hazards.

To maintain peak dust control performance, adherence to a structured daily maintenance routine is imperative. The following steps outline a recommended maintenance schedule based on factory best practices:

| Maintenance Task | Frequency | Details |

|---|---|---|

| Seal Integrity Inspection | Daily | Visual and tactile checks for abrasion or gaps in sealing elements, especially after shift changes. |

| Filter Cartridge Replacement | Monthly or after 200 operating hours | Replace high-efficiency particulate air (HEPA) filters according to dust load to maintain vacuum airflow. |

| Vacuum System Cleaning | Weekly | Clear dust buildup in vacuum ducts and check pump function to prevent performance degradation. |

| Workshop Environment Management | Continuously | Maintain positive air pressure and humidity levels between 40-60% to minimize dust suspension. |

A leading graphite tooling manufacturer incorporated the DC6060G dry vacuum machining centers into their production line in 2022. Within the first year, documented machine uptime increased from 82% to 96%, while unscheduled maintenance related to dust contamination fell by nearly 70%.

Operators reported substantially improved machining accuracy and reduced tool wear rates, translating into annual cost savings exceeding $120,000. The manufacturer emphasizes that commitment to a disciplined maintenance regimen combined with the machine's full-seal and dust extraction technologies was critical to these results.

For manufacturing leaders committed to operational excellence, the DC6060G machining center—featuring industry-leading full sealing and vacuum dust control—represents a strategic asset that significantly lowers downtime and maintenance rates while promoting a healthier work environment.