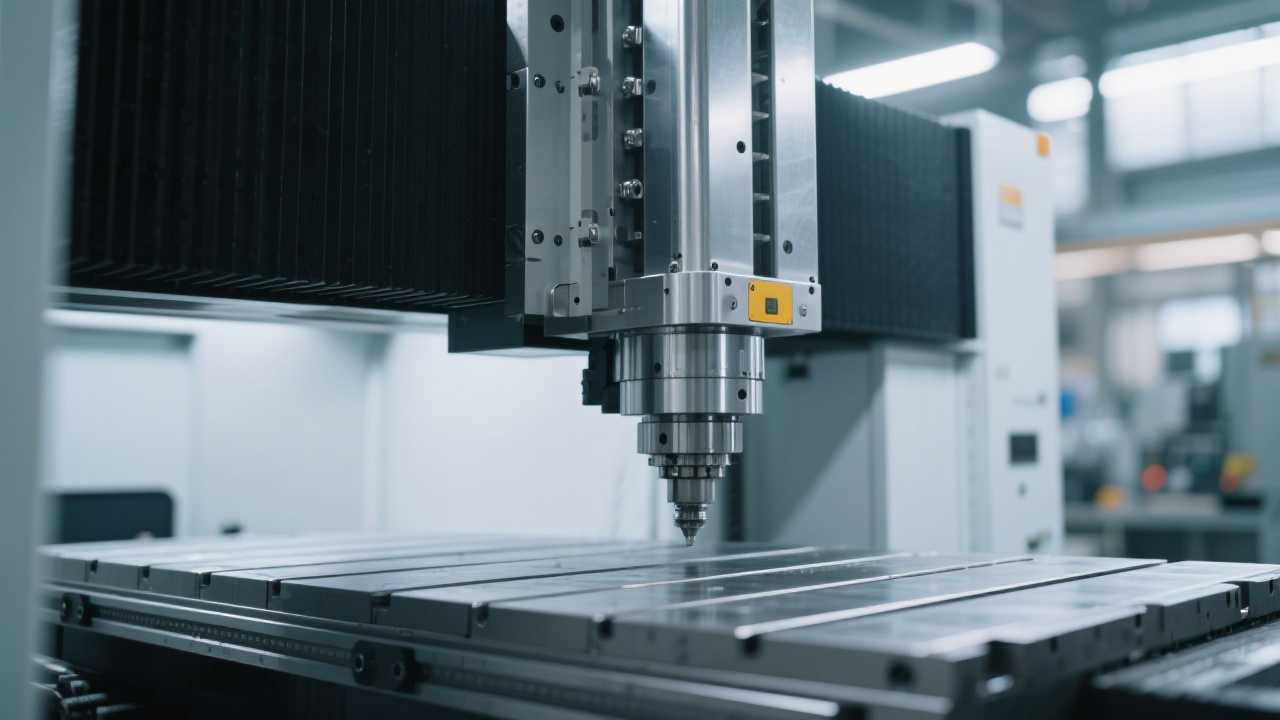

In demanding graphite machining environments, the conflicting demands of dust prevention and heat dissipation pose significant challenges for equipment longevity and operational reliability. The DC6060G wet washing graphite machining center exemplifies how an intelligently engineered fully sealed enclosure can harmonize these requirements through sophisticated material selection, advanced sealing techniques, and optimized airflow design. This article delves into the underlying principles enabling this balance and highlights real-world benefits observed in high-purity manufacturing sectors such as lithium battery electrode fabrication and aerospace component production.

Graphite processing inherently generates fine particulate matter, rendering dust ingress a critical risk factor for precision machine components. Traditional opening or ventilated designs facilitate heat dissipation but expose components to abrasive dust, accelerating wear and triggering unplanned downtimes. Conversely, fully sealed enclosures safeguard against contamination but challenge conventional cooling methods, risking thermal accumulation that degrades system performance.

The DC6060G's enclosure employs high-performance polymer composite materials notable for their thermal stability, durability, and chemical resistance. These materials form a robust barrier that withstands acidic cooling fluids used in wet washing processes while minimizing thermal conductivity to protect sensitive internal electronics.

Dynamic sealing interfaces incorporate multi-layered elastomer gaskets engineered for continuous motion compatibility without sacrificing tightness. This approach prevents dust ingress during mechanical articulation and ensures long-term sealing integrity under thermal cycling. The careful balance between gasket compressibility and mechanical resilience is vital to maintain the enclosure’s “breathability” analog, much like a precision-calibrated respiratory membrane in living organisms.

Heat dissipation is achieved via a controlled ventilation network embedded within the sealed shell. Strategically designed internal baffles generate directed airflow pathways, ensuring turbulent boundary layers are minimized over heat-sensitive components. The enclosure incorporates high-capacity heat exchangers interfaced with closed-loop temperature sensors, enabling dynamic adjustment of fan speed and coolant flow based on thermal loads.

This “smart” cooling system emulates a biologically inspired thermoregulation mechanism — akin to how mammals maintain homeostasis through sweat and adjusted blood flow — enabling the DC6060G to sustain optimal operating temperatures without compromising dust protection.

Empirical data from prominent lithium battery electrode manufacturers reveal the DC6060G’s design achievements: the device has lowered equipment fault rates by approximately 30% and reduced maintenance downtimes by 40% compared to conventional open-frame alternatives over 12 months of continuous operation. Such improvements directly translate to enhanced production continuity, lower operational expenditure, and prolonged asset life cycles.

| Metric | DC6060G Fully Sealed System | Traditional Open System | Improvement |

|---|---|---|---|

| Fault Rate (%) | 2.3 | 3.3 | -30.3% |

| Maintenance Downtime (hrs/year) | 120 | 200 | -40% |

Beyond graphite machining, the principles embedded in the DC6060G’s enclosure design resonate strongly within aerospace manufacturing and other domains where particulate contamination and thermal management coexist as critical hurdles. The proven enhancement in equipment durability and process consistency positions this technology as a pivotal element in achieving industry 4.0 targets for automation and quality assurance.

By conceptualizing the sealed enclosure as the "respiratory system" of the machining center, engineers can appreciate the nuanced trade-offs between maintaining an impermeable dust barrier and enabling essential thermal ‘breathing’—a paradigm that informs future advancements in smart machining system design.