As the shoe mold manufacturing industry continues to evolve, the demand for higher precision and efficiency is ever - increasing. Five - axis CNC milling machines have emerged as a game - changer in this field. In this guide, we'll walk you through the operation of the DC6060A five - axis last CNC milling machine, a powerful tool that can significantly enhance your shoe mold production.

Traditional shoe mold manufacturing methods often face challenges such as low precision and inefficiency. With the complexity of modern shoe designs, especially the need for precise and complex curved surfaces, five - axis CNC milling machines have become indispensable. They can handle intricate geometries with ease, reducing the time and cost associated with manual labor. In fact, studies show that using a five - axis CNC milling machine can increase production efficiency by up to 40% compared to traditional methods.

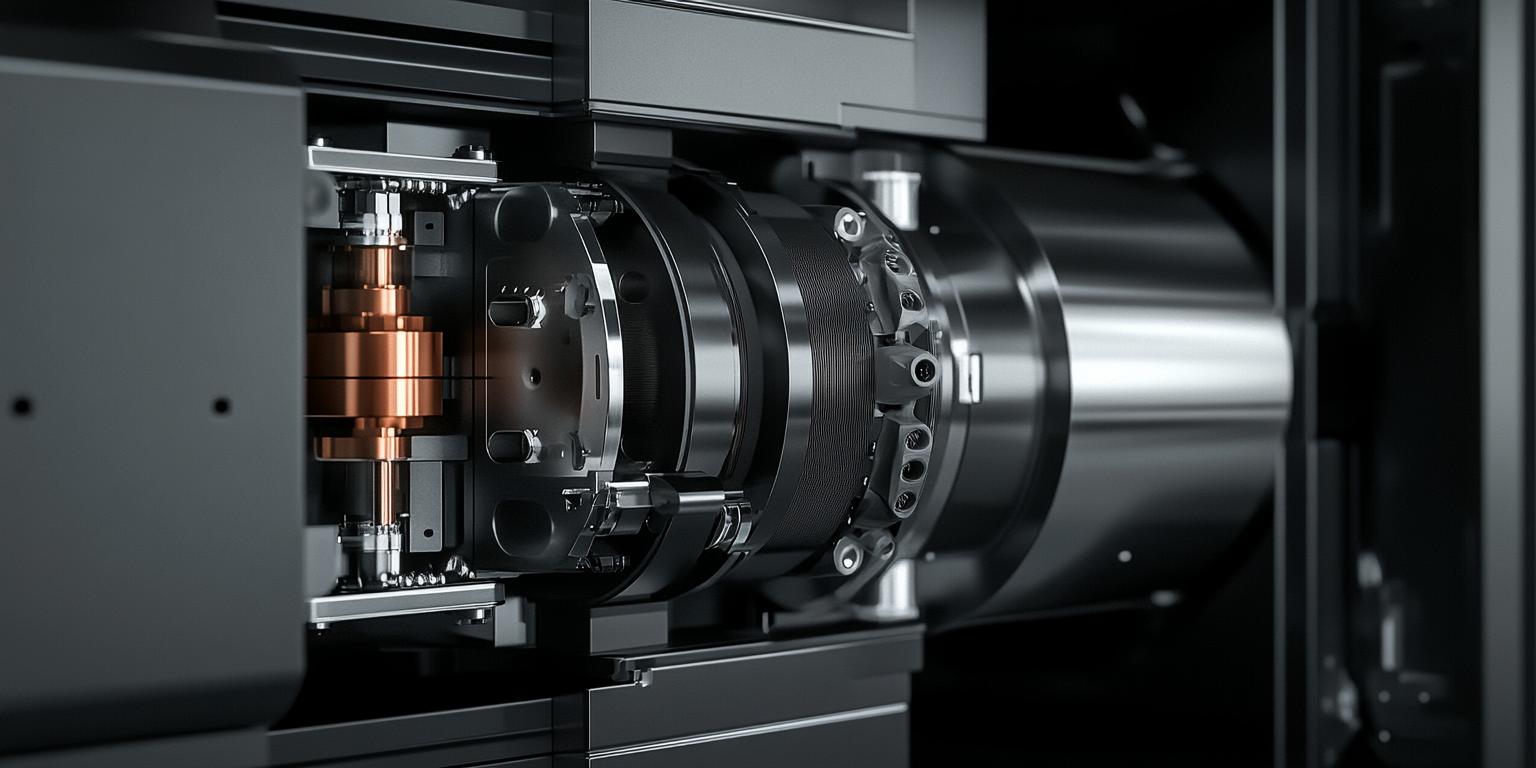

The DC6060A is equipped with a state - of - the - art rotary table. This design allows for multi - angle machining, enabling you to create complex shoe mold shapes without re - clamping the workpiece. It can rotate smoothly and accurately, with a positioning accuracy of up to ±0.005 degrees, ensuring high - precision machining.

The machine's multi - axis linkage system is another highlight. It can synchronize the movement of multiple axes, such as the X, Y, Z, A, and C axes, to achieve seamless machining of complex surfaces. The multi - axis linkage precision is within ±0.01mm, which is crucial for creating shoe molds that fit the foot perfectly.

| Step | Description |

|---|---|

| Workpiece Loading | Secure the shoe mold blank on the rotary table using appropriate fixtures. Make sure it is firmly fixed to prevent any movement during machining. |

| Tool Selection | Choose the right cutting tools based on the material of the shoe mold blank and the required machining accuracy. For example, carbide end mills are often used for high - speed machining of hard materials. |

| Tool Path Setting | Use CAD/CAM software to generate the tool path. Consider factors such as cutting speed, feed rate, and depth of cut to ensure efficient and accurate machining. |

Vibration can be caused by improper tool installation, unbalanced workpieces, or machine instability. To correct this, check and tighten the toolholder, balance the workpiece, and adjust the machine's leveling.

Long - term machining can generate heat, leading to thermal deformation of the machine and the workpiece. Use coolant to control the temperature and allow the machine to cool down periodically.

Positioning deviation may occur due to inaccurate fixture installation or errors in the CNC program. Double - check the fixture alignment and verify the CNC program to correct this issue.

Regular maintenance is essential for the long - term stability of the DC6060A. This includes cleaning the machine, lubricating moving parts, and checking electrical connections. Parameter optimization, such as adjusting the cutting parameters based on the actual machining situation, can also improve the machining quality and extend the machine's service life. By following a strict maintenance schedule, you can reduce the machine's downtime by up to 30%.

Many shoe mold manufacturers have benefited from using the DC6060A. For example, a factory in Italy increased its shoe mold production yield from 80% to 95% after implementing the operation methods described in this guide. They also reduced the production time per mold by 25%, resulting in significant cost savings and increased competitiveness in the market.

Industry experts believe that "The DC6060A five - axis last CNC milling machine is a revolutionary tool in the shoe mold manufacturing industry, offering unparalleled precision and efficiency."