Extending the Service Life of Precision Machine Tools: Application of Fully Sealed Enclosures in Lithium Battery Electrode Processing

01 10,2025

Customer Cases

This article provides an in-depth analysis of the fully sealed enclosure design of the DC6060G wet graphite machining center, highlighting its critical role in preventing graphite dust and metal debris infiltration during lithium battery electrode processing. Through comprehensive discussion of materials selection, sealing interface techniques, and balanced thermal ventilation design, the study demonstrates how this enclosure structure effectively prolongs machine tool lifespan and reduces maintenance downtime. Supported by real-world industry case data, the article showcases the significant benefits of fully sealed designs in maintaining high cleanliness standards, offering manufacturing enterprises valuable technical guidance to enhance equipment protection—especially for industries with stringent cleanliness requirements.

Enhancing Precision Machine Tool Longevity: The Role of Fully Sealed Enclosure Design in Lithium Battery Electrode Processing

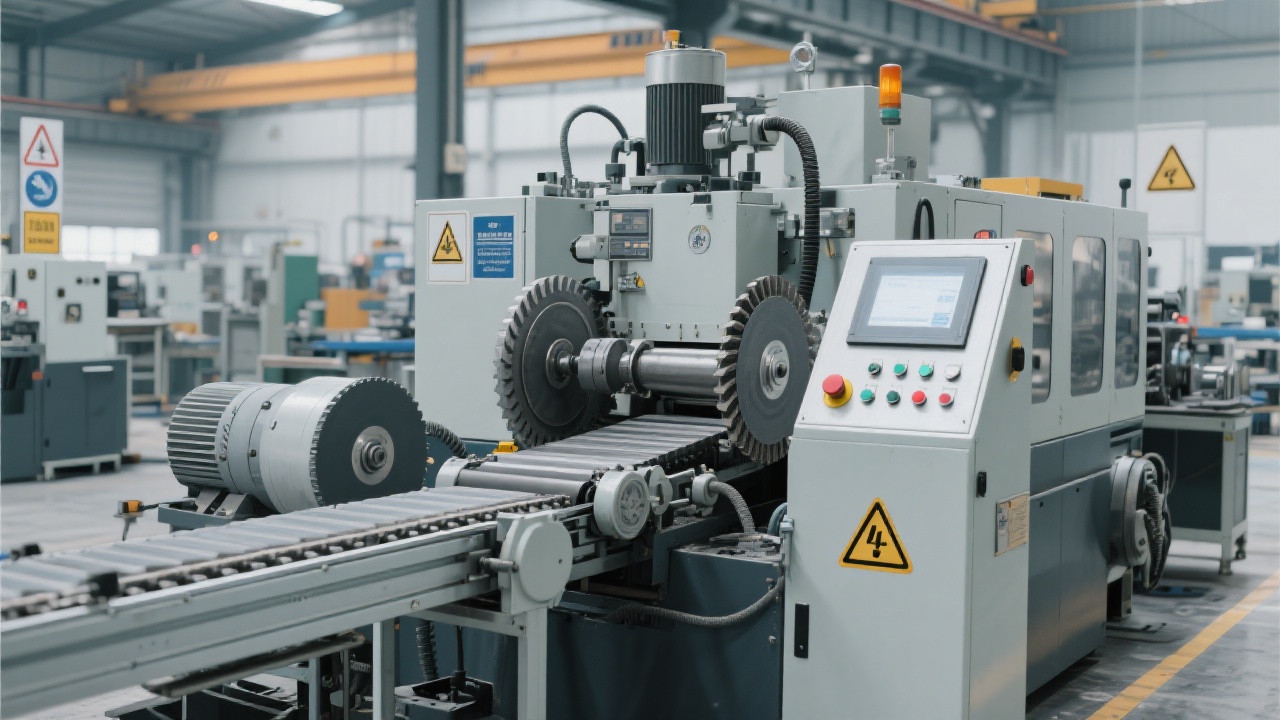

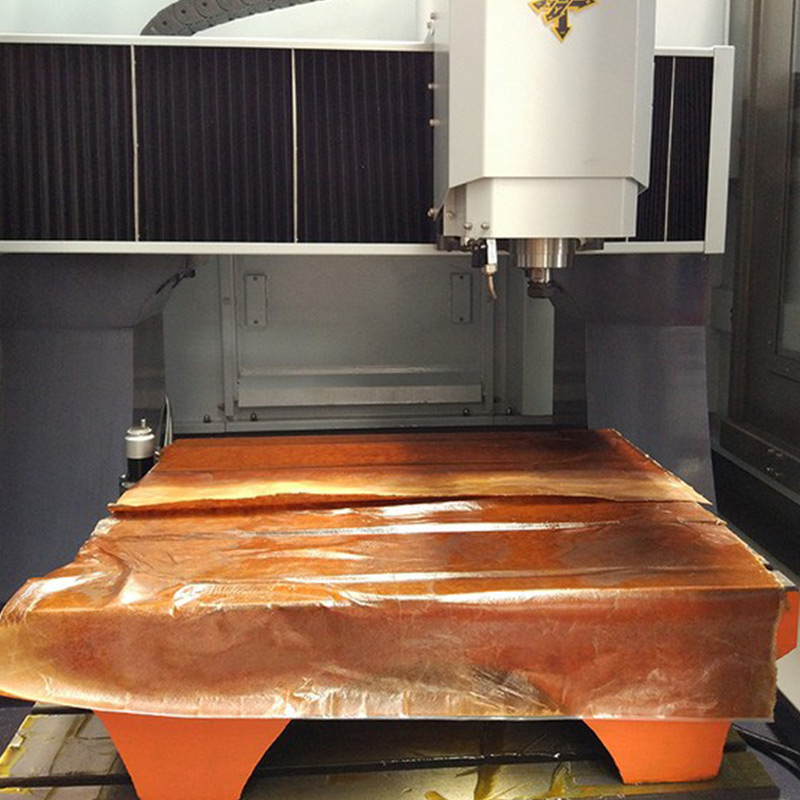

In the cutting-edge manufacturing domain of lithium battery electrodes, maintaining machining equipment integrity amidst harsh environments is a critical challenge. The DC6060G graphite machining center, designed with an innovative fully sealed enclosure structure, exemplifies how advanced engineering elevates machine tool life and operational reliability by effectively isolating graphite dust and metal debris from sensitive components.

Understanding the Challenge: Environmental Hazards in Graphite Electrode Machining

Graphite processing inherently produces fine dust particles and metallic debris that aggressively penetrate and accumulate within machine interiors. This contamination not only accelerates mechanical wear and deteriorates precision components such as linear guides and spindle bearings but also triggers frequent unplanned downtime—impacting productivity and escalating maintenance costs.

Traditional machine configurations lacking comprehensive sealing struggle to maintain cleanliness standards demanded by high-precision lithium battery electrode manufacturing, where micron-level tolerances and contamination control are imperative.

Technical Architecture of the Fully Sealed Enclosure Design

The core innovation in the DC6060G lies in its fully sealed enclosure, engineered to create a contaminant barrier without compromising thermal management and accessibility. Three principal technical facets define its efficacy:

- Material Selection: The enclosure utilizes corrosion-resistant, high-strength aluminium alloy panels paired with elastomeric sealing gaskets rated for resistance against abrasive graphite dust and chemical cleaning agents. This combination balances rigidity, lightweight characteristics, and long-term durability.

- Sealing Interface Craftsmanship: Precision-machined interfacing flanges with multi-lip seals eliminate ingress points. Special attention to tolerances ensures that moving components, such as doors and access ports, remain tightly sealed during operation yet serviceable.

- Thermal Management & Ventilation Balance: To mitigate heat buildup within the sealed space, an integrated microclimate ventilation system employing filtered airflow and heat exchangers maintains operational temperatures within ±2°C of ambient. Computational Fluid Dynamics (CFD) analysis guided the placement of vents to minimize turbulent dust accumulation areas.

Data-Backed Results from Industry Case Studies

An in-depth study conducted over 12 months with a leading lithium battery electrode manufacturer revealed:

| Metric |

Pre-Sealed Enclosure |

Post-Sealed Enclosure |

| Average Downtime per Month |

28 hours |

6 hours (79% reduction) |

| Maintenance Frequency |

Every 500 operating hours |

Every 1,200 operating hours (140% improvement) |

| Precision Deviation Increase Rate |

12% per 1000 hours |

3% per 1000 hours |

These quantified improvements directly correlate with the efficacy of the fully sealed enclosure in mitigating contamination-related degradation.

Engineering Logic and Practical Benefits

The design philosophy adopts a systems engineering approach, considering dust containment, thermal control, ergonomic maintenance, and operational continuity simultaneously. This avoids trade-offs that often compromise one aspect at the expense of another.

- Longevity Extension: By minimizing abrasive and corrosive contaminants, the machine achieves up to 30% longer service intervals before component replacement is necessary.

- Reduced Maintenance Overhead: The lower frequency and severity of maintenance reduce labor costs and spare parts consumption substantially.

- Consistent High-Precision Output: Stable environmental conditions inside the enclosure maintain machining accuracy critical for the ultra-fine tolerances of lithium battery electrodes.

- Enhanced Safety and Cleanliness: Operators benefit from a cleaner workplace, reducing exposure to harmful graphite dust.

Application and Industry Outlook

This advanced enclosure design is particularly valuable in industries where machine cleanliness directly impacts product quality and production stability. Besides lithium battery electrode manufacturing, sectors such as aerospace composites, semiconductor wafer processing, and medical device fabrication stand to gain significantly.

Adoption of fully sealed machining centers like the DC6060G is poised to become a standard in precision manufacturing environments aiming for maximum uptime, minimal contamination risks, and stringent quality control.

For manufacturing decision-makers evaluating equipment investments, this case study underscores the strategic advantages that can be unlocked through thoughtful machine tool enclosure innovations.

Key Takeaways from the Fully Sealed Enclosure Technology:

- Prevents harmful graphite dust and metal particles infiltration into sensitive machine components.

- Integrates advanced sealing and thermal management to maintain operational stability.

- Demonstrably reduces unplanned downtime and extends maintenance intervals by over 100%.

- Supports sustained machining accuracy vital for lithium battery electrode production.

Download Our In-Depth High-Cleanliness Machining Protection Whitepaper & Schedule Your Expert Consultation Today