Graphite processing has long been plagued by challenges such as dust and metal shavings pollution. These issues not only affect the working environment but also pose serious health risks to operators and damage sensitive equipment. The DC6060G Dry-Vacuum Graphite Machining Center is a revolutionary solution designed to address these pain points head-on, offering an advanced, clean, and efficient way to process graphite materials.

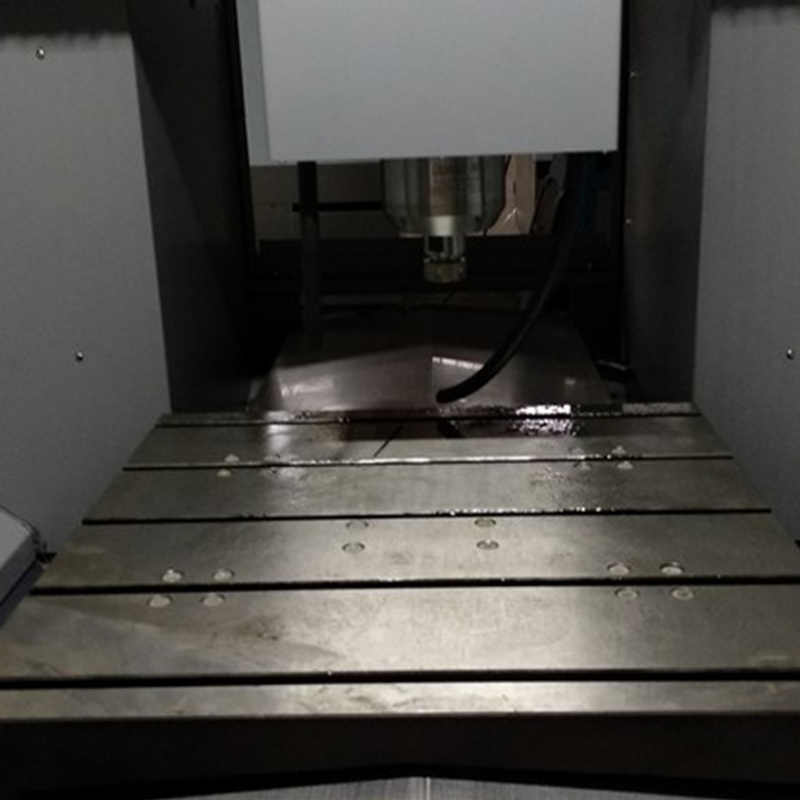

The DC6060G features a fully enclosed hood design, which creates a sealed environment during machining operations. This ensures that all dust and debris generated are contained within the machine, preventing them from spreading into the surrounding area. Compared to traditional machining centers, where dust often escapes and contaminates the workshop, the DC6060G significantly improves air quality and reduces the need for frequent cleaning and maintenance.

In addition to its fully enclosed structure, the DC6060G is equipped with a powerful vacuum dust collection system. This system continuously captures and removes fine particles, ensuring that even the smallest graphite dust is effectively managed. According to internal testing data, the vacuum system can capture over 98% of airborne particles, making it one of the most effective solutions on the market.

To illustrate the effectiveness of the DC6060G, let's look at a real-world case study. A leading manufacturer in the aerospace industry was struggling with excessive dust and metal shavings in their production facility. After switching to the DC6060G, they reported a 75% reduction in dust levels and a significant improvement in worker safety and equipment longevity. Their maintenance costs dropped by nearly 40%, and overall productivity increased due to fewer interruptions caused by cleaning and repairs.

Another customer, a high-tech electronics company, shared similar feedback. They had previously used conventional machining centers, but the constant accumulation of graphite dust led to frequent machine downtime and quality issues. Since implementing the DC6060G, they have experienced consistent performance, reduced waste, and improved product quality. Their team now operates in a cleaner, safer environment, which has boosted morale and efficiency.

What sets the DC6060G apart is its ability to deliver both precision and cleanliness in one machine. Unlike other systems that require additional dust collection units or complex ventilation setups, the DC6060G integrates all necessary functions into a single, compact unit. This not only saves space but also simplifies operation and reduces the overall cost of ownership.

For companies looking to enhance their graphite processing capabilities while maintaining a safe and sustainable work environment, the DC6060G offers a compelling solution. Its advanced design, proven performance, and user-friendly features make it an ideal choice for manufacturers across various industries.

Ready to experience the future of graphite machining? Join our community of satisfied customers and take the first step toward a cleaner, more efficient production process. Request a Free Consultation Today and discover how the DC6060G can transform your workflow.