In the field of graphite machining, traditional machine tools often face challenges such as component corrosion and dust pollution. These issues not only reduce the service life of the machine but also affect the quality of the machining process. To address these pain points, we introduce the wet - flush graphite machining center DC6060G, which is based on the optimized design of the CNC milling machine DC6060A.

Graphite machining generates a large amount of fine dust and metal chips. According to industry statistics, about 70% of traditional graphite machining machines experience varying degrees of component corrosion within two years due to dust and chip contamination. These fine particles can easily penetrate into the internal parts of the machine, causing wear and tear on moving components, electrical short - circuits, and ultimately leading to machine failure.

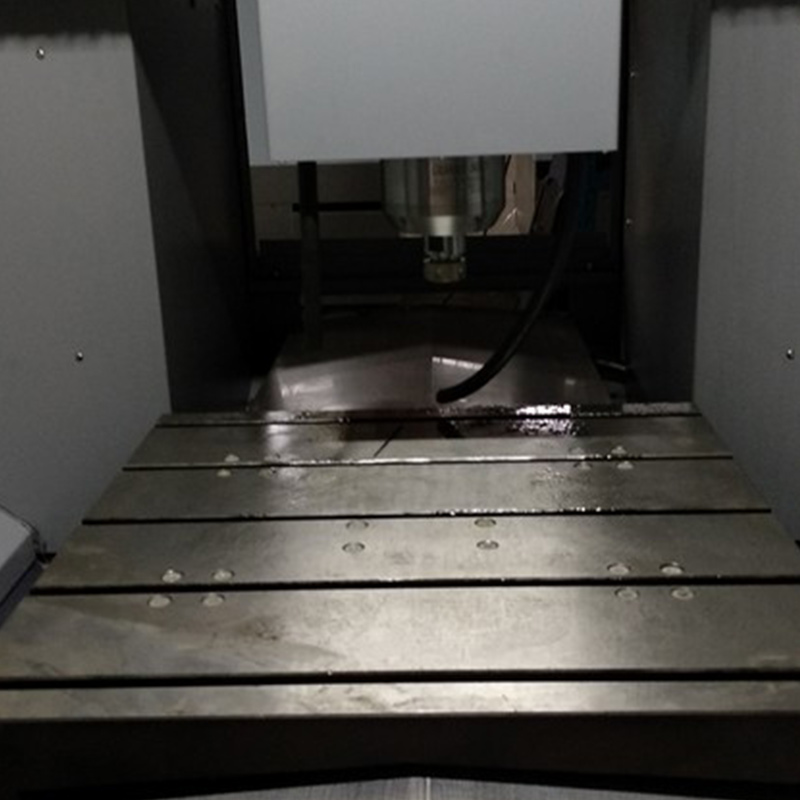

The DC6060G features a full - sealed cover design. This design effectively prevents graphite dust and metal chips from entering the interior of the machine. Compared with traditional open - frame machines, the full - sealed cover reduces the probability of internal component corrosion by up to 90%. The sealed structure creates a clean working environment for the machine's internal components, greatly extending the service life of the machine. For example, a customer in Germany reported that after using the DC6060G for three years, there was no obvious corrosion on the internal components of the machine, while their previous traditional machine needed major repairs after only one and a half years.

The wet - flush system is another core innovation of the DC6060G. During the machining process, the system continuously sprays a special cleaning fluid to wash away graphite dust and metal chips. This not only keeps the machining area clean but also cools the cutting tool, improving the cutting quality. In a comparative test, the surface roughness of the graphite parts machined by the DC6060G was reduced by 30% compared with traditional dry - machining methods, greatly improving the product quality.

A well - known graphite product manufacturer in the United States had long been troubled by the high maintenance cost of their traditional machining equipment. After switching to the DC6060G, they saw significant improvements. In the first year of use, the maintenance cost was reduced by 40%, and the production efficiency increased by 25%. The high - quality machining results also helped them win more high - end orders, improving their market competitiveness.

The DC6060G wet - flush graphite machining center, with its innovative full - sealed cover design and wet - flush system, effectively solves the common problems in graphite machining. It offers better protection for the machine, improves machining quality, and reduces maintenance costs. If you are looking for a reliable and efficient graphite machining solution, the DC6060G is your ideal choice.

Learn more about the DC6060G and its innovative features. Click here to contact our online customer service or call our consulting hotline to start your graphite machining upgrade journey!