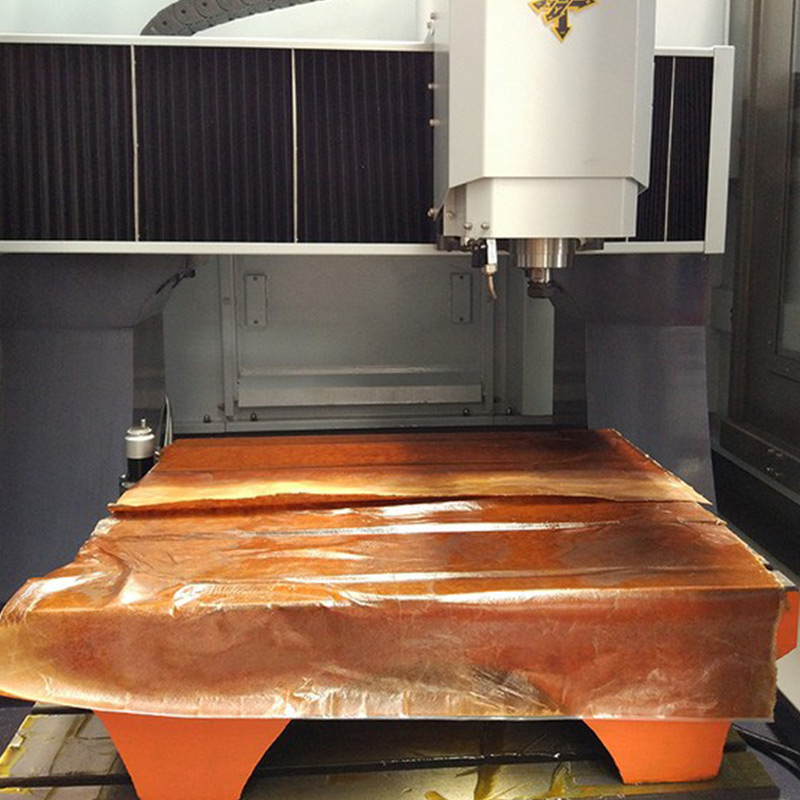

In the high-precision realm of graphite machining, the infiltration of dust particles and metal debris into machine tools is a persistent challenge, often leading to repeated failures and soaring maintenance costs. Especially for wet-wash graphite machining centers like the DC6060G, robust protective measures are crucial to maintain operational stability and manufacturing quality.

Graphite processing environments inherently produce fine dust and metallic residues that easily penetrate poorly sealed machine tool interfaces. This contamination causes electronic component corrosion, accelerates precision degradation, and inevitably increases machine downtime. Furthermore, traditional sealing techniques often fail to provide sustained protection amid dynamically moving parts and fluctuating thermal conditions.

The DC6060G's design team approached the sealing challenge with a comprehensive methodology incorporating:

This tri-fold approach synergistically functions as a "breathing system" for the machine tool—allowing controlled airflow for temperature regulation while barring contaminants, akin to a respiratory defense mechanism in a biological system.

Industry-specific trials, particularly within lithium battery electrode manufacturers, have substantiated the efficacy of this sealing technology. Key performance metrics include:

| Metric | Baseline (Traditional Sealing) | With Full-Seal Design |

|---|---|---|

| Mean Time Between Failures (MTBF) | 1,000 hours | 1,300+ hours (30%↑) |

| Maintenance Frequency | Every 500 hours | Every 750+ hours (33%↑ interval) |

| Operational Stability (Precision Deviation) | ±0.015 mm | ±0.008 mm (~47% Improvement) |

"Since integrating the improved full-sealing solution, our wet-wash graphite centers have experienced significantly fewer unscheduled downtimes, directly impacting our production efficiency and reducing maintenance overhead." – Senior Engineer, Leading Lithium Battery Manufacturer

Beyond graphite processing, this advanced protective architecture presents transformative potential for sectors demanding extreme precision and contamination control—such as:

The well-calibrated balance between sealing robustness and thermal airflow ensures these sectors can achieve longer equipment lifespans and greater process repeatability, with tangible ROI from reduced downtime and servicing.

Discover how your precision manufacturing can benefit from advanced machine tool protection — Download Our Free Whitepaper on High-Cleanliness Machining Center Protection or Schedule a Technical Consultation Today.