In the graphite processing industry, manufacturers often face numerous challenges. Graphite dust pollution is one of the most prominent issues. It can corrode machine components, reduce the service life of the equipment, and even affect the health of operators. These pain points have long troubled industry players, urging them to seek more advanced and reliable equipment.

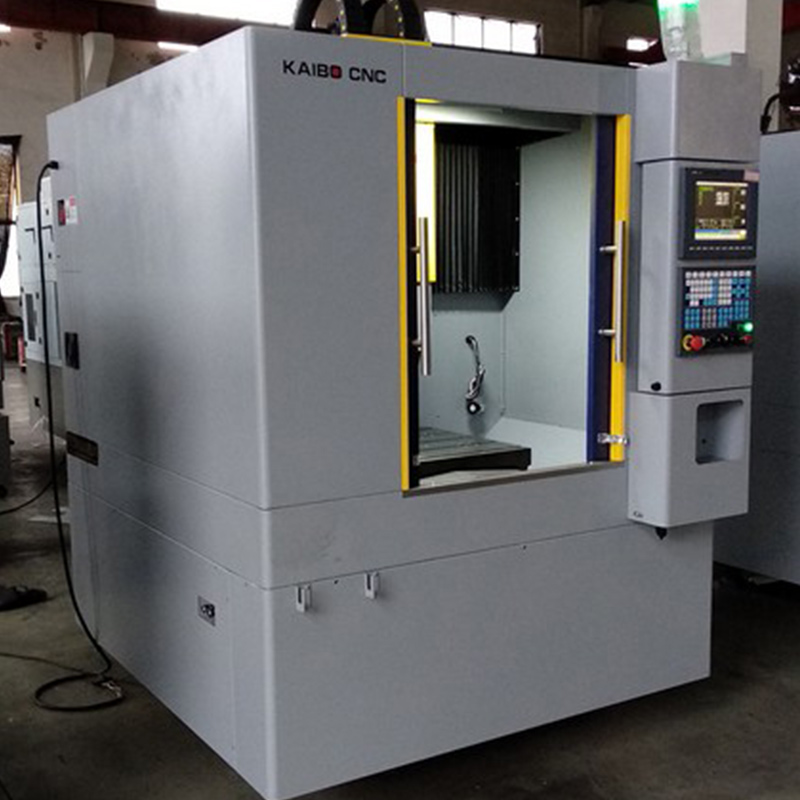

This is where the Dry Vacuum Graphite Machining Center DC6060G comes into play. The DC6060G is designed based on the CNC milling machine DC6060A. The R & D team behind it has deeply considered the problems existing in the graphite processing field. They aimed to develop a machine that can effectively solve the problems of dust pollution and corrosion while improving processing efficiency and quality.

One of the most significant advantages of the DC6060G is its full-sealed enclosure design inside the machine. Compared with ordinary CNC milling machines, this design can effectively prevent corrosive substances and graphite dust from entering the machine's interior. In an ordinary CNC milling machine, without proper protection, graphite dust can easily accumulate on key components such as the spindle and guide rails. According to relevant data, in a graphite processing environment, the dust deposition rate on the components of ordinary CNC milling machines can reach about 30% within a month, which seriously affects the performance and accuracy of the machine. In contrast, the full-sealed enclosure design of the DC6060G reduces the dust deposition rate to less than 5%, greatly extending the service life of the machine.

Another core advantage is its dust suction device. During the graphite processing, a large amount of dust will be generated. The dust suction device of the DC6060G can quickly and effectively remove these graphite dust. Tests have shown that the dust removal efficiency of the DC6060G can reach 95%, while the dust removal efficiency of ordinary CNC milling machines is only about 60%. This means that in the processing process, the DC6060G can maintain a cleaner processing environment, reduce the impact of dust on the processing quality, and improve the surface finish of the graphite products.

Let's take a graphite processing factory as an example. Before using the DC6060G, they used ordinary CNC milling machines. The machines often had problems such as reduced accuracy and component failures due to dust pollution. They had to replace some key components every six months, which not only increased the cost but also affected the production schedule. After replacing with the DC6060G, the situation has been greatly improved. The service life of the machine has been extended to more than two years, and the processing quality has also been significantly improved. The rejection rate of graphite products has dropped from 8% to less than 2%.

In conclusion, the DC6060G has significantly improved in performance and protection compared with ordinary CNC milling machines, and it can better meet the needs of graphite processing. If you are also troubled by the problems in graphite processing, the DC6060G is definitely a worthy choice. Welcome to further consult us to learn more about this excellent product!