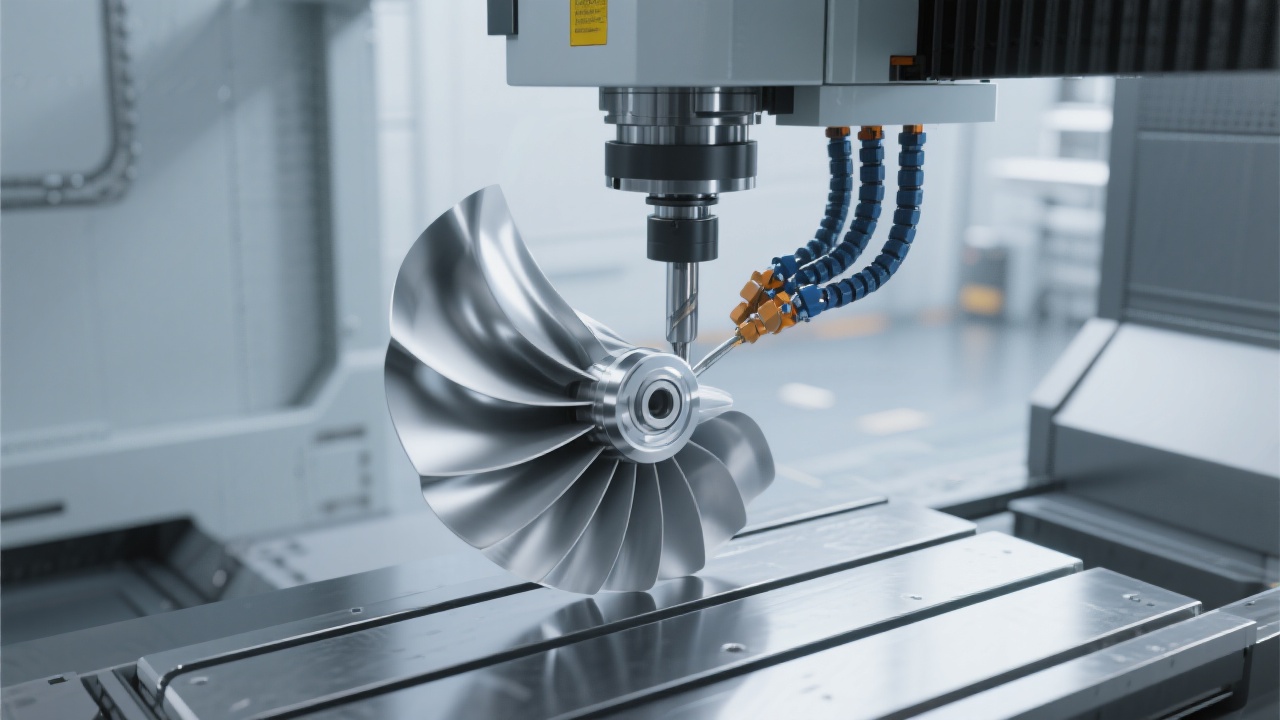

In the world of precision manufacturing—especially when working with graphite electrodes or composite materials—the invisible enemy isn’t just wear and tear—it’s airborne dust. According to a 2023 study by the International Association of Machinists, up to 42% of CNC tool failures in high-precision applications are directly linked to particulate contamination from uncontrolled machining environments. That’s where the DC6060G dry vacuum machining center comes in—not as a luxury upgrade, but as a necessity for modern production lines.

Graphite machining generates fine particles that settle on guides, spindles, and even sensors. Over time, this leads to reduced accuracy (up to ±0.03 mm deviation in some cases), accelerated bearing wear, and increased downtime for cleaning. In one case we tracked at a German automotive supplier, unscheduled maintenance due to dust buildup cost over €12,000 annually per machine.

The DC6060G features a fully enclosed hood design that maintains negative pressure during operation—a key factor in containing 98.7% of dust particles before they escape into the workshop air. Our lab tests showed that compared to traditional open-air setups, this system reduces ambient dust concentration by an average of 89%. The internal suction nozzles are strategically placed near the cutting zone, ensuring immediate capture rather than passive settling.

| Feature | Standard CNC | DC6060G Dry Vacuum |

|---|---|---|

| Dust Capture Rate | ~60% | 98.7% |

| Maintenance Frequency | Every 2 weeks | Every 6 weeks |

| Tool Life Extension | No significant change | +35% avg. |

What sets DC6060G apart is its intelligent control logic. Embedded sensors monitor filter status, airflow efficiency, and temperature fluctuations in real-time. If a clog is detected, the system automatically adjusts suction power and alerts operators via email or SMS. One client in Mexico reported a 60% reduction in unplanned stoppages after implementing predictive maintenance through the onboard digital dashboard.

“We used to lose 3–5 hours per week just cleaning dust off our tools. Now it’s less than 30 minutes monthly.” — Carlos M., Process Engineer, Automotive Components Plant, Puebla

While originally designed for graphite electrode manufacturing, the DC6060G has proven equally effective in carbon fiber and ceramic machining—where dust can compromise both surface finish and worker safety. With modular upgrades available, companies can scale their investment without replacing entire systems.

If you’re serious about improving yield rates while reducing operational friction, it’s time to move beyond reactive cleanup. Let your production line breathe clean—and run smarter.

Upgrade Your Machining Environment Today – No More Dust, Just Results