In the graphite processing industry, dust and metal chips pollution have long been a headache for manufacturers. These pollutants not only pose a threat to the health of workers but also significantly reduce the service life of processing equipment. However, the Dry Vacuum Graphite Machining Center DC6060G emerges as a game - changer, offering a perfect solution to these problems.

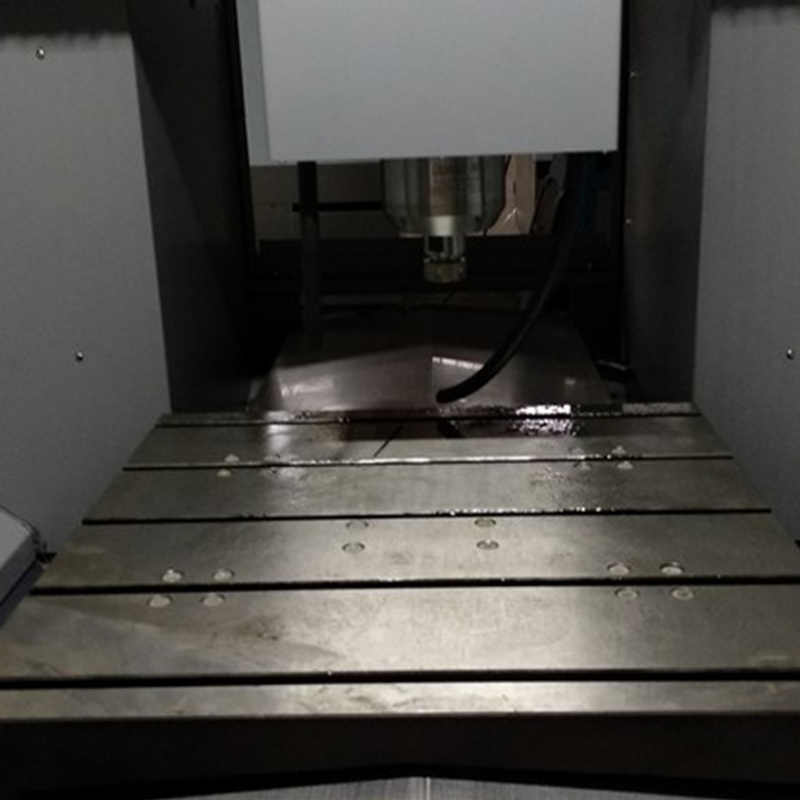

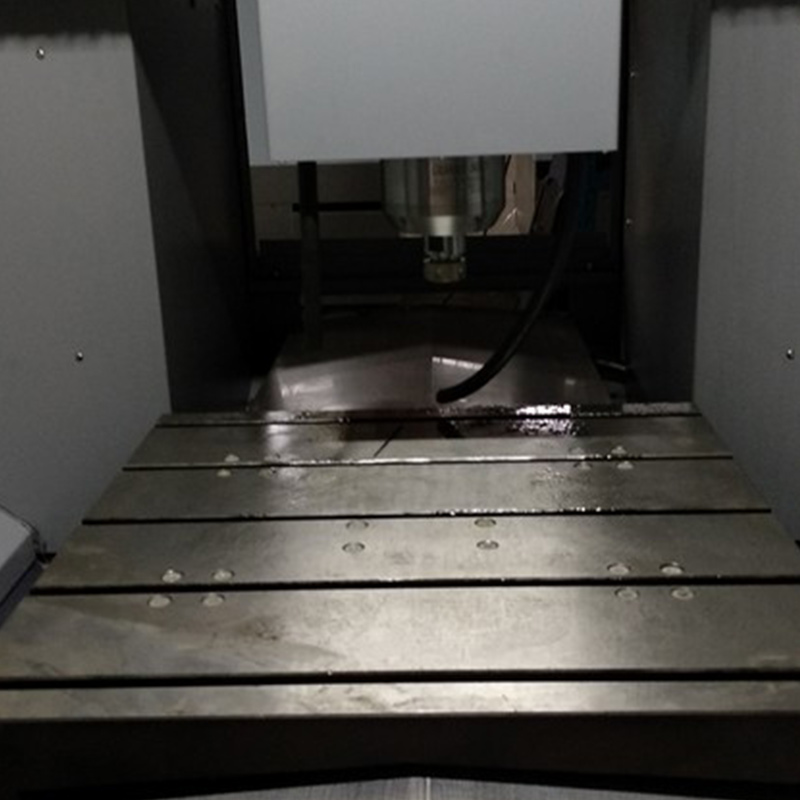

The DC6060G is designed based on the CNC milling machine DC6060A. One of its most remarkable features is the full - sealed cover design. This design effectively isolates the machining area from the external environment, preventing graphite dust and metal chips from spreading. In contrast, ordinary machining centers often lack such a comprehensive sealing structure, leading to an average dust leakage rate of up to 30%. This means that a large amount of dust will be released into the workshop environment, causing potential harm to workers and equipment.

Another highlight of the DC6060G is its powerful dust suction device. With a high - efficiency dust collection system, it can collect and remove up to 95% of graphite dust during the processing. This not only keeps the machining area clean but also reduces the need for frequent equipment maintenance. In comparison, ordinary machining centers usually have a dust collection efficiency of only about 60%, which means a large amount of dust will accumulate on the equipment surface and inside the machine, affecting its performance and service life.

Let's take a look at some real - world customer cases to understand the effectiveness of the DC6060G. A graphite processing factory in Germany used to suffer from serious dust pollution problems. After using the DC6060G, the dust concentration in the workshop decreased by 80%, and the equipment failure rate dropped by 40%. The factory not only improved the working environment for its employees but also significantly increased production efficiency.

In addition, a Japanese graphite product manufacturer also reported positive results. After replacing the old machining center with the DC6060G, the quality of their products improved significantly. The rejection rate of graphite products decreased from 15% to 5%, which directly increased their market competitiveness.

We encourage you to share your thoughts and experiences in graphite processing. Have you ever encountered dust pollution problems in your factory? How do you think the DC6060G can help you solve these problems? Leave your comments below and join the discussion!

If you are tired of dealing with graphite dust pollution in your processing operations, the Dry Vacuum Graphite Machining Center DC6060G is your ideal choice. It can effectively solve your dust pollution problems and improve your production efficiency. Contact us now to learn more about this amazing product and take the first step towards a cleaner and more efficient graphite processing environment!