Graphite machining is a critical process in industries such as semiconductor manufacturing, aerospace, and battery production. However, it often faces a serious challenge—dust pollution. Traditional machining centers release large amounts of fine graphite dust and metal shavings into the air, posing risks to both equipment and workers' health. This issue has long been a pain point for manufacturers around the world.

During the machining process, graphite particles are generated due to cutting, grinding, and drilling. These particles are extremely fine, with some measuring less than 10 microns. When not properly controlled, they can spread throughout the workshop, leading to poor air quality, increased maintenance costs, and even safety hazards.

According to a recent industry report, over 70% of graphite machining facilities experience significant dust issues, with 40% reporting health-related complaints from workers. In addition, uncontrolled dust can damage sensitive equipment and reduce product quality, resulting in costly downtime and rework.

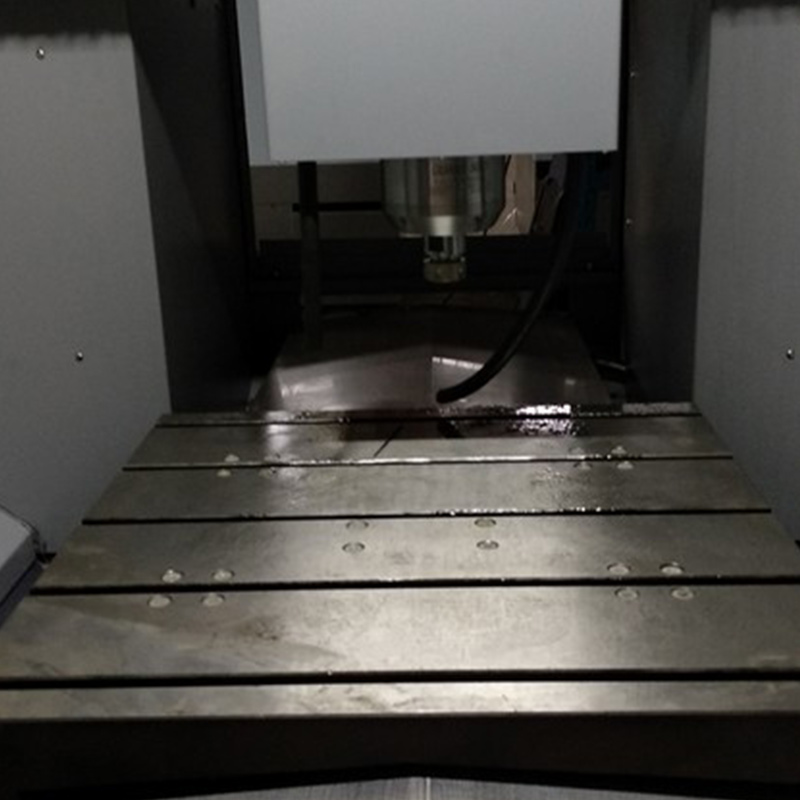

Designed specifically to address these challenges, the DC6060G dry vacuum graphite machining center features a fully sealed enclosure and an advanced dust extraction system. This innovative design ensures that dust and debris are captured at the source, preventing them from entering the workspace.

Compared to traditional machining centers, the DC6060G offers several key advantages:

| Feature | DC6060G | Traditional Machine |

|---|---|---|

| Dust Control System | Integrated vacuum system with high-efficiency filters | Basic exhaust fan only |

| Enclosure Design | Fully sealed structure to prevent dust leakage | Open or semi-enclosed design |

| Work Environment | Clean and safe for operators | High risk of exposure to airborne particles |

The DC6060G’s fully sealed enclosure acts as a barrier between the machining area and the rest of the workshop. Combined with its powerful vacuum system, it captures up to 99.9% of dust particles, ensuring a clean and safe working environment.

A major manufacturer in the lithium battery industry faced severe dust issues with their existing graphite machining setup. After switching to the DC6060G, they reported a 95% reduction in airborne dust levels within the first month. Additionally, the company noted a 30% decrease in maintenance costs and a significant improvement in worker satisfaction.

“Since we installed the DC6060G, our workshop has become much cleaner and safer. Our employees no longer suffer from respiratory issues, and our production efficiency has improved,” said a plant manager from the company.

This case demonstrates the effectiveness of the DC6060G in real-world conditions. With its advanced design and proven performance, it is becoming a preferred choice for manufacturers looking to improve their dust control capabilities.

The DC6060G is not just a machine—it's a comprehensive solution to the problem of graphite machining dust. It delivers:

If you're facing dust pollution challenges in your graphite machining operations, the DC6060G is the right choice. Don’t let dust compromise your business. Take the next step toward a cleaner, safer, and more efficient production environment.

Join thousands of satisfied customers who have already upgraded to the DC6060G. Discover how this advanced machining center can help you solve dust pollution and boost your production efficiency.

Get Started Today