In the graphite machining industry, machine tools often face significant challenges from graphite dust and metal chips. These contaminants can infiltrate machine components, leading to increased wear and tear, reduced precision, and frequent breakdowns. For instance, studies have shown that in unprotected machining environments, the lifespan of machine tools can be reduced by up to 30% due to the abrasive nature of graphite dust.

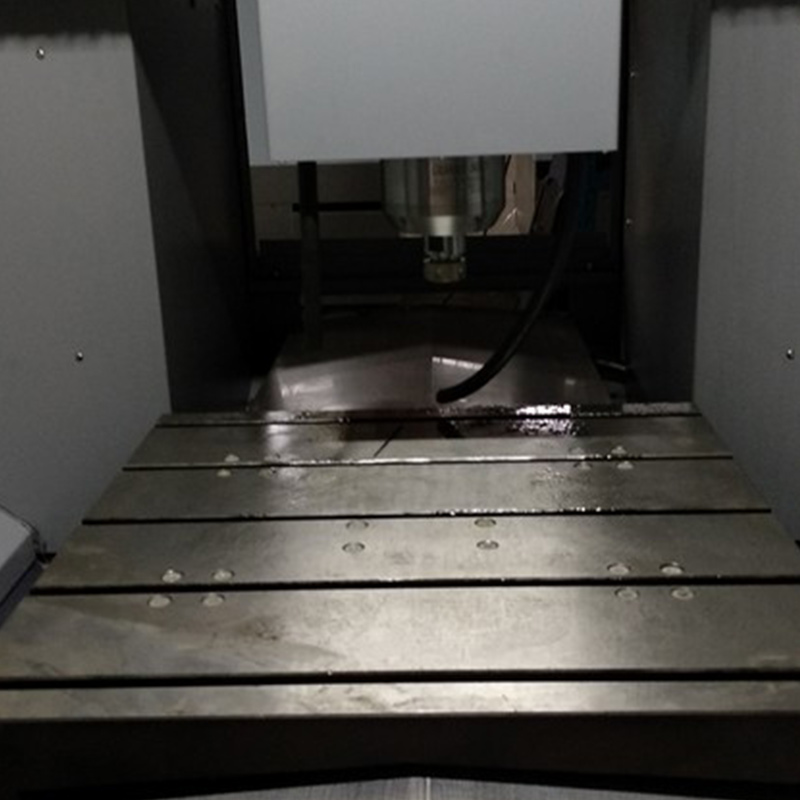

The Dry Vacuum Graphite Machining Center DC6060G offers a game - changing solution with its full sealing enclosure design. This design effectively prevents graphite dust and metal chips from escaping the machining area. Independent tests have demonstrated that the DC6060G can reduce dust leakage by over 95% compared to traditional open - type machining centers.

The enhanced protection provided by the full sealing enclosure directly translates into improved production efficiency. A customer from Germany reported that after switching to the DC6060G, their machine downtime for maintenance decreased by 40%. This reduction in downtime allowed them to increase their monthly production output by approximately 25%, significantly boosting their overall profitability.

The dust collection system of the DC6060G is another key feature. It operates on a high - efficiency suction principle, quickly capturing graphite dust and metal chips as soon as they are generated. The system can achieve a dust collection efficiency of up to 98%, ensuring a clean machining environment.

The impact on machining precision and product quality is remarkable. A customer in Japan shared that before using the DC6060G, their product rejection rate due to surface defects caused by dust was around 10%. After adopting the DC6060G, the rejection rate dropped to less than 2%, saving them a substantial amount of production costs.

| Features | DC6060G | Competitor Products |

|---|---|---|

| Dust Leakage Rate | Less than 5% | Around 20% |

| Dust Collection Efficiency | Up to 98% | Around 80% |

| Production Downtime for Maintenance | Reduced by 40% | Minimal reduction |

Apart from the aforementioned customers in Germany and Japan, many other companies around the world have benefited from the DC6060G. A customer in the United States reported that the DC6060G's reliability and high - precision machining capabilities have helped them win more high - end contracts, expanding their market share in the industry.

These success stories are a testament to the DC6060G's ability to solve real - world problems in the graphite machining industry and drive business growth.

Don't miss out on the opportunity to enhance your production efficiency, improve product quality, and reduce costs. Contact us today to learn more about the Dry Vacuum Graphite Machining Center DC6060G and request a free trial. Our team of experts is standing by to assist you!