In the high - precision graphite machining industry, dust pollution has always been a significant challenge. This article delves into two primary dust control solutions: dry dust collection and wet flushing, aiming to provide a comprehensive comparison for industry professionals and decision - makers.

Dry dust collection systems operate by using filters to capture dust particles generated during the graphite machining process. These filters can be made of various materials, such as fabric or paper, and they work by allowing air to pass through while trapping dust. According to industry statistics, dry dust collection systems can achieve a dust removal efficiency of up to 90% in general graphite machining environments.

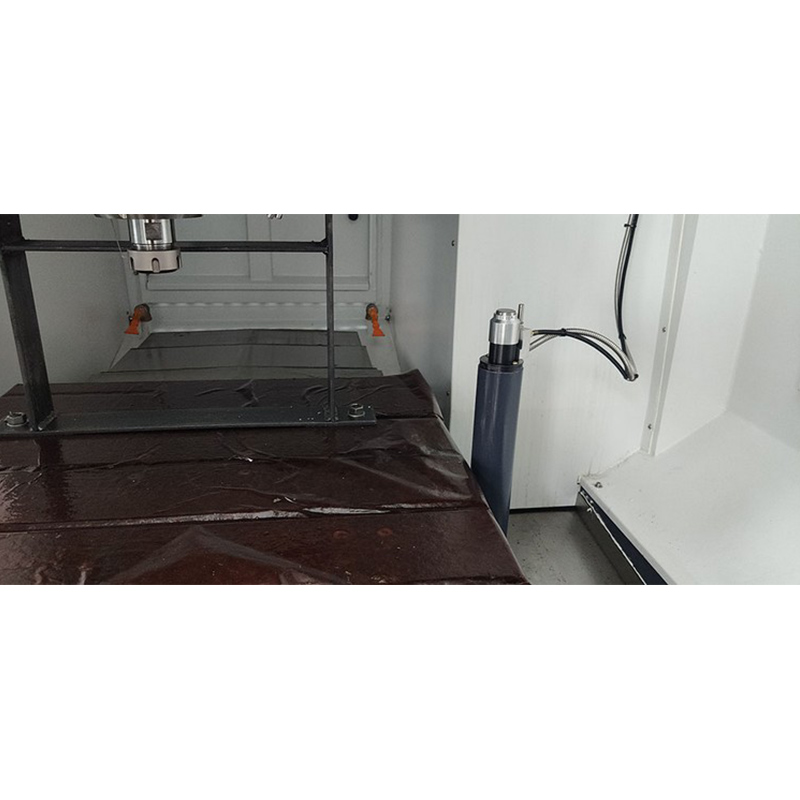

On the other hand, wet flushing systems rely on water to suppress and collect dust. The core components of a wet flushing system include a spray design, water pressure adjustment, and a filtration and recovery mechanism. The spray design is crucial as it determines how evenly the water is distributed to capture dust. By adjusting the water pressure, the system can effectively control the range and intensity of the water spray. The filtration and recovery mechanism is responsible for separating dust from the water and recycling the water for reuse, which not only reduces water consumption but also minimizes environmental impact.

When comparing dry dust collection and wet flushing, each method has its own set of advantages and disadvantages. Dry dust collection systems are relatively simple in structure and easy to install. They do not require a large amount of water, which is beneficial in areas with water shortages. However, dry dust collection systems may have limitations in capturing fine dust particles, especially in high - precision graphite machining where the dust particles are extremely small. In addition, the filters in dry dust collection systems need to be replaced regularly, which increases the operating cost.

Wet flushing systems, on the other hand, have several significant advantages in high - precision graphite machining. Firstly, they can effectively capture fine dust particles, ensuring a cleaner working environment. Secondly, wet flushing systems can reduce the risk of dust explosion, which is a major safety concern in graphite machining. For example, in a high - precision CNC machining environment, the use of wet flushing systems can reduce the dust concentration in the air by up to 95%, significantly improving the safety of the workplace. However, wet flushing systems require a more complex infrastructure, including water supply, drainage, and filtration systems, and they also need regular maintenance to prevent clogging and other issues.

To better understand the effectiveness of wet flushing systems, let's look at some real - world application cases. In a high - precision graphite machining factory, a wet flushing system was integrated into a CNC machine. The spray design of the wet flushing system was optimized to ensure that the water could cover the entire machining area. By adjusting the water pressure, the system was able to effectively capture dust without causing excessive splashing. The filtration and recovery mechanism of the system was also well - designed, which could separate more than 90% of the dust from the water, allowing the water to be recycled. As a result, the dust concentration in the workshop was significantly reduced, and the quality of the machined graphite products was improved.

To ensure the long - term stable operation of wet flushing systems, regular maintenance and troubleshooting are essential. For maintenance, it is necessary to check the water pipes regularly to ensure that there are no leaks or blockages. The filters in the filtration and recovery mechanism also need to be cleaned or replaced regularly to maintain their filtering efficiency. When it comes to troubleshooting, common issues such as low water pressure or abnormal water spray can usually be resolved by checking the water pump, valves, and nozzles. By following these maintenance and troubleshooting methods, the reliability and safety of the wet flushing system can be significantly improved.

If you are looking for a reliable dust control solution for high - precision graphite machining, our advanced wet flushing systems can provide you with the best performance and efficiency. Click here to learn more about our wet flushing systems and how they can transform your graphite machining process!