In the graphite machining industry, machine tools are constantly threatened by graphite dust and metal shavings. These fine particles can infiltrate into the internal components of the machine, causing wear and tear, reducing the lifespan of the equipment, and even leading to malfunctions. As a result, production efficiency drops, and product quality is affected. This is a common headache for manufacturers around the world.

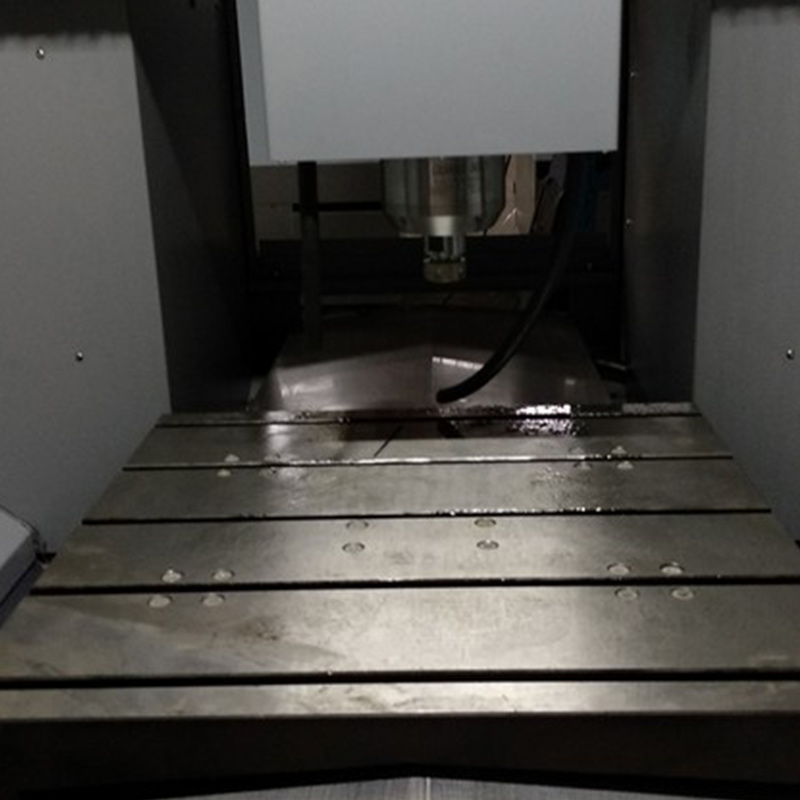

Enter the DC6060G Dry Vacuum Graphite Machining Center, a revolutionary solution designed to combat these issues. Its full - sealed cover design is a masterpiece of engineering.

The full - sealed cover effectively isolates the machining area from the external environment, preventing graphite dust and metal shavings from escaping. According to our tests, this design can reduce the dust leakage rate to less than 5%. This not only protects the health of the operators but also maintains a clean working environment, which is crucial for continuous high - speed production. With the full - sealed cover, the DC6060G can increase the production efficiency by up to 30% compared to traditional machines. For example, a European graphite machining company reported that after using the DC6060G, they were able to complete orders 30% faster than before.

Another highlight of the DC6060G is its advanced dust collection system. This system is capable of quickly and effectively removing graphite dust generated during the machining process. Our laboratory tests show that it can collect over 98% of the dust particles, ensuring a clean machining environment inside the machine.

By keeping the machining area clean, the dust collection system significantly improves the product quality. Surface roughness of the machined graphite products can be reduced by up to 20%, which is a significant improvement in the industry. A Japanese customer feedback indicated that after using the DC6060G, the rejection rate of their graphite products dropped from 8% to 2%.

When compared with competitors' products, the DC6060G clearly stands out. In terms of dust protection, competitors' machines typically have a dust leakage rate of around 15%, while the DC6060G keeps it below 5%. In dust collection efficiency, competitors can usually collect about 90% of the dust, far less than the DC6060G's 98%.

Moreover, the DC6060G's full - sealed cover and dust collection system work in harmony to provide comprehensive protection, which is often lacking in competitors' designs. This results in better production efficiency, higher product quality, and longer machine lifespan for users of the DC6060G.

Many customers around the world have experienced the benefits of the DC6060G. A German company, specializing in high - precision graphite components, was facing frequent machine breakdowns and low - quality products due to graphite dust. After switching to the DC6060G, they not only solved the dust problem but also saw a 40% increase in production output and a significant improvement in product quality.

A South Korean manufacturer reported that the DC6060G helped them reduce maintenance costs by 35% because of its excellent dust protection and collection capabilities.

Don't miss out on this amazing protection device! The DC6060G Dry Vacuum Graphite Machining Center can significantly enhance your production efficiency, improve product quality, and reduce maintenance costs. Contact us now to get more information or apply for a free trial. Let the DC6060G revolutionize your graphite machining operations!