In the graphite machining industry, machine tools often face significant challenges from graphite dust and metal chips. These fine particles can infiltrate machine components, causing accelerated wear and tear, reducing precision, and even leading to frequent breakdowns. This not only increases maintenance costs but also severely affects production efficiency and product quality. Amidst these challenges, the DC6060G Dry Vacuum Graphite Machining Center emerges as a reliable solution.

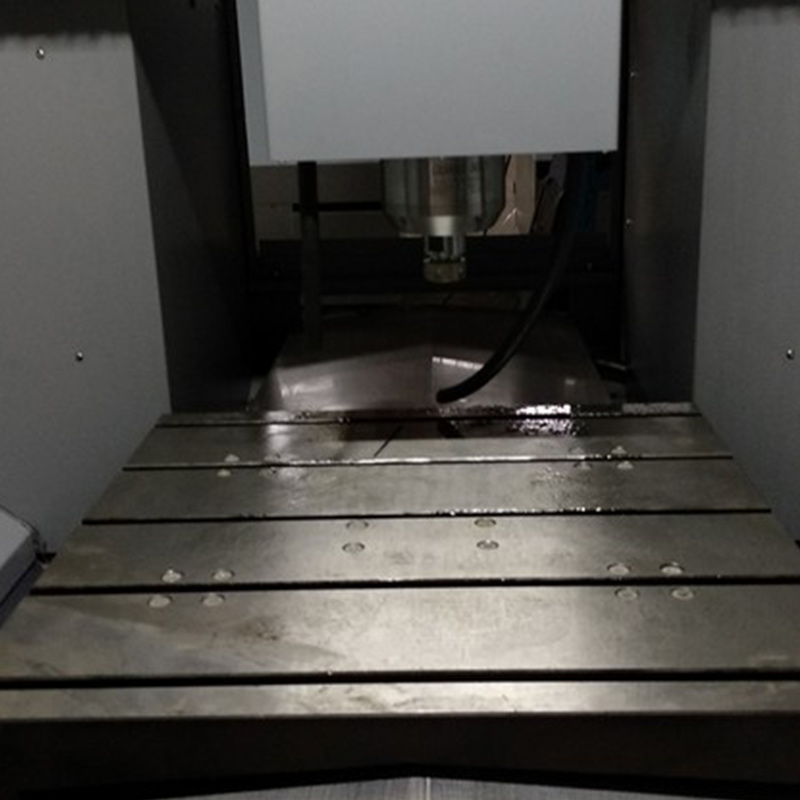

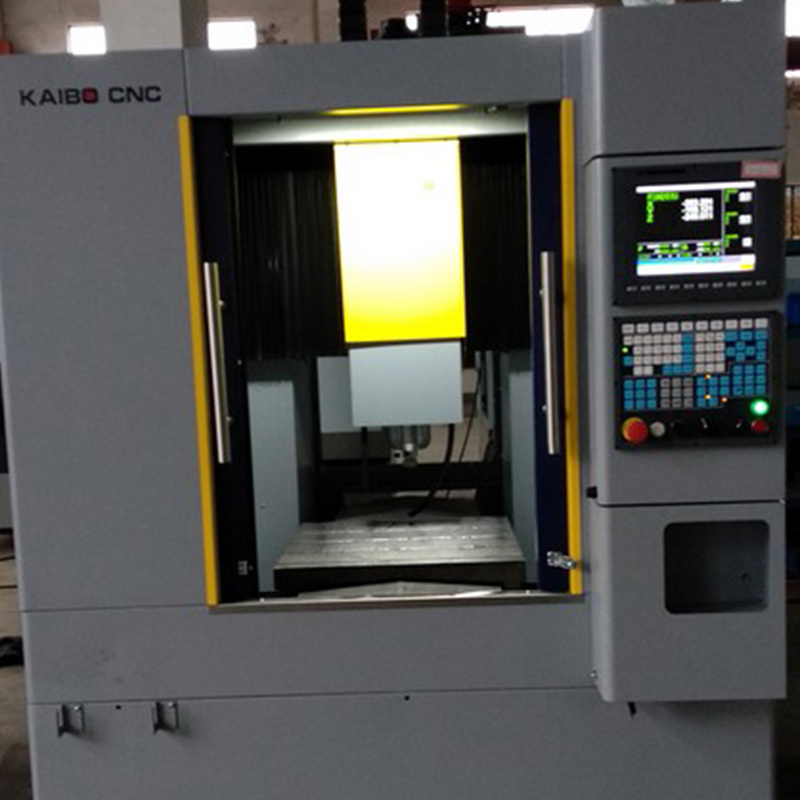

The DC6060G features an all - sealed enclosure design, which can be likened to a well - fortified fortress. It effectively isolates the machining area from the external environment, preventing graphite dust and metal chips from escaping and causing damage to other parts of the machine or the workshop environment.

According to practical data, with the all - sealed enclosure design, the probability of machine malfunctions caused by dust and chip infiltration is reduced by up to 80%. This significant reduction in malfunctions directly translates into increased production efficiency. For example, a graphite machining factory in Germany used to experience an average of 10 machine breakdowns per month before switching to the DC6060G. After using this machine, the number of breakdowns dropped to only 2 per month, allowing them to increase their monthly production volume by 30%.

The dust collection device of the DC6060G is another key feature that enhances its protective performance. The working principle of this device is based on a high - power suction system that quickly captures graphite dust and metal chips generated during the machining process.

It has been shown that the dust collection efficiency of the DC6060G's dust collection device can reach up to 95%. This high - efficiency dust collection ensures that the machining environment remains clean, which is crucial for maintaining the precision of the machining process. A customer feedback from a Japanese company stated that since they started using the DC6060G, the rejection rate of their graphite products has decreased from 5% to 1%, significantly improving their product quality and market competitiveness.

When compared with other competing products in the market, the DC6060G stands out in terms of its protective performance. Most competing products may have partial enclosure designs or less efficient dust collection systems. For instance, some competitors' machines only have an average dust collection efficiency of around 70%, which means a large amount of dust remains in the machining area, posing risks to the machine and product quality.

In addition, the all - sealed enclosure of the DC6060G provides a more comprehensive protection compared to the semi - open enclosures of some competitors. This difference in design results in a much lower probability of machine failures and a higher level of product quality consistency.

Many customers around the world have benefited from using the DC6060G. A graphite component manufacturer in the United States was struggling with high maintenance costs and low product quality due to the poor performance of their previous machines. After adopting the DC6060G, they not only reduced their maintenance costs by 40% but also improved their product quality to meet the strict requirements of high - end customers. This enabled them to expand their market share and increase their annual revenue by 25%.

Don't miss out on the opportunity to enhance your graphite machining operations. The DC6060G offers superior protective performance, increased production efficiency, and improved product quality.

Don't hesitate any longer. Contact us immediately to inquire about product details or apply for a trial. Let the DC6060G safeguard your production!