In the graphite machining industry, ordinary CNC milling machines often face persistent challenges due to contamination from graphite dust and metal chips. These issues not only lead to frequent breakdowns but also pose risks to the health of operators. Enter the Dry Vacuum Graphite Machining Center DC6060G, a remarkable upgrade based on the CNC milling machine DC6060A. Let's delve into its details.

The R & D team recognized the limitations of ordinary CNC milling machines. The presence of graphite dust and metal chips could easily corrode machine parts and electronic components, shortening the machine's lifespan and increasing maintenance costs. Their goal was to develop a machine that could effectively address these problems while maintaining high - precision machining capabilities. Based on the DC6060A, they introduced a series of improvements to create the DC6060G.

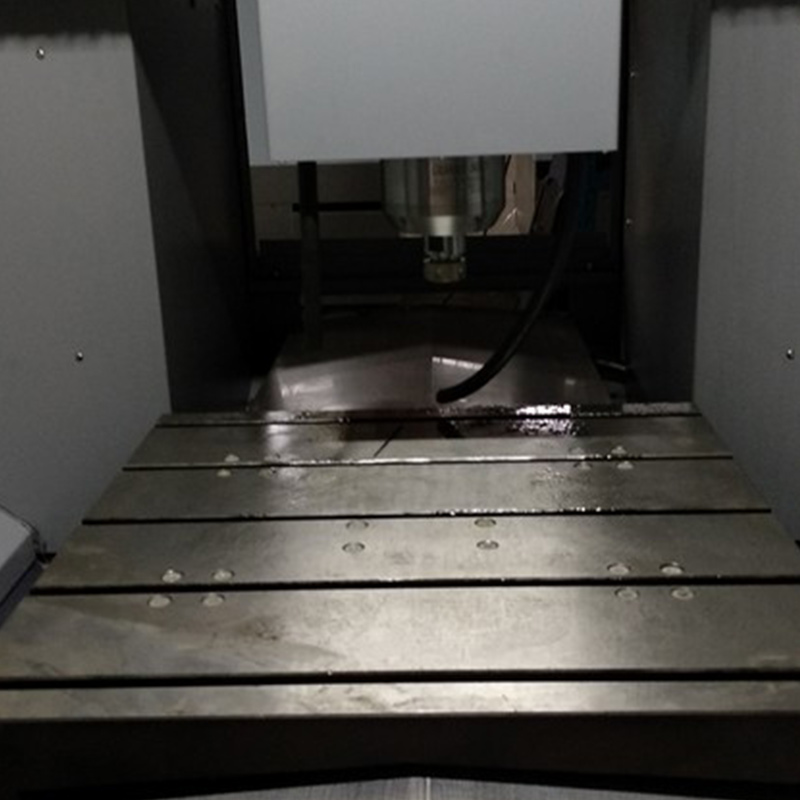

The DC6060G features a fully sealed enclosure design inside the machine. This design serves as a protective barrier, preventing graphite dust and metal chips from entering the internal components. Unlike ordinary CNC milling machines, where the internal parts are directly exposed to the contaminated environment, the sealed enclosure of the DC6060G significantly reduces the risk of corrosion and damage. For example, in a traditional CNC milling machine, the failure rate of electronic components due to dust and chip contamination can reach up to 30% within a year. In contrast, the DC6060G has reduced this failure rate to less than 5%.

The DC6060G is equipped with a powerful dust collection device. This device works by creating a vacuum that sucks in graphite dust generated during the machining process. It can collect up to 98% of the graphite dust, leaving the working environment clean and safe for operators. In a workshop using an ordinary CNC milling machine, the dust concentration in the air can reach 10 mg/m³, which is far above the safe standard. However, with the DC6060G, the dust concentration can be reduced to less than 1 mg/m³, greatly improving the working conditions.

After using the DC6060G, many customers have reported significant improvements. For instance, a graphite machining factory in Germany reduced its machine maintenance costs by 40% after replacing its old CNC milling machines with the DC6060G. Another customer in Japan saw a 35% increase in production efficiency due to fewer machine breakdowns. These real - world examples demonstrate the reliability and performance of the DC6060G.

Missing out on the Dry Vacuum Graphite Machining Center DC6060G means missing a chance to upgrade your graphite machining operations. With its advanced design, high - efficiency dust collection, and proven performance, it is a game - changer in the industry. If you want to learn more about this amazing product, please contact our sales team at [Contact Email] or call us at [Contact Phone Number]. Don't hesitate to take the first step towards a more efficient and reliable graphite machining process!