Graphite machining is a crucial process in various industries, including electronics, aerospace, and automotive. However, it comes with significant challenges, especially the issue of dust pollution. Traditional machining centers often struggle to effectively control graphite dust, which not only poses health risks to operators but also shortens the lifespan of the equipment due to dust accumulation. In fact, studies show that nearly 70% of equipment failures in graphite machining are related to dust problems. This is where the DC6060G dry vacuum graphite machining center steps in to revolutionize the industry.

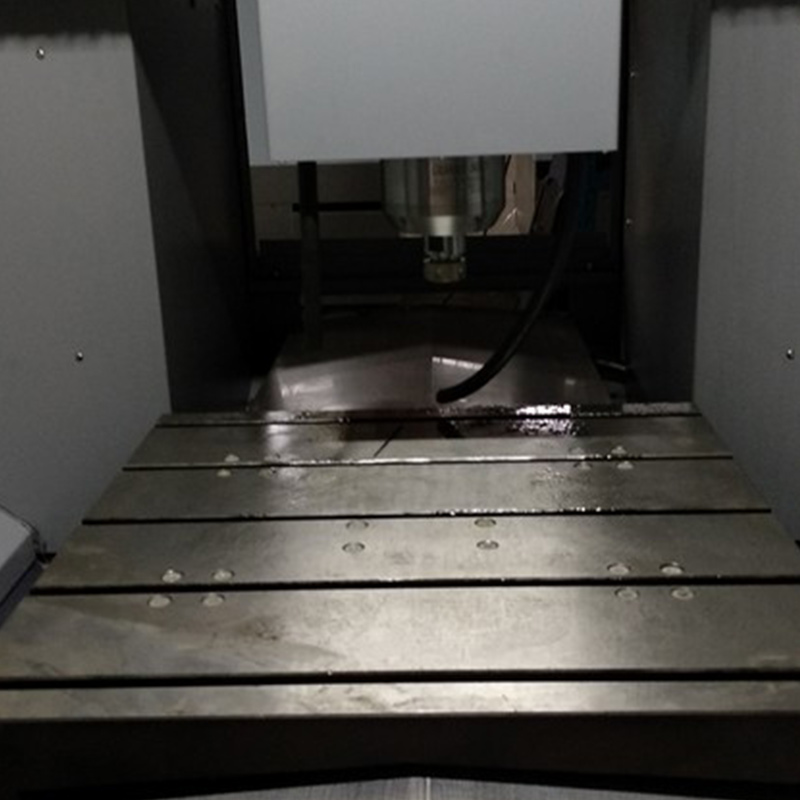

The DC6060G features a fully enclosed cover design, which is a game - changer in graphite machining. In contrast, ordinary machining centers usually have an open or semi - open structure, allowing graphite dust to spread freely. The fully enclosed cover of the DC6060G effectively prevents dust from escaping into the working environment. It creates a sealed space where the machining process takes place, protecting operators from inhaling harmful dust particles. According to our research, this design can reduce the dust concentration in the working area by up to 90%, providing a much safer and cleaner working environment.

Another outstanding feature of the DC6060G is its advanced dust collection device. While ordinary machining centers may have basic dust collection systems, they often fail to capture fine graphite dust effectively. The DC6060G's dust collection device is equipped with high - efficiency filters and a powerful suction system. It can quickly and thoroughly collect graphite dust generated during the machining process. Tests have shown that it can collect over 95% of the dust, ensuring that the internal components of the machine are not damaged by dust accumulation. This not only extends the service life of the equipment but also reduces maintenance costs by up to 30%.

Many customers have already experienced the benefits of the DC6060G. For example, a European graphite machining company was facing high equipment failure rates and poor working conditions due to dust pollution. After switching to the DC6060G, they noticed a significant improvement. The dust concentration in their workshop decreased significantly, and the equipment failure rate dropped by 40%. As a result, their production efficiency increased by 25%, and they were able to save a large amount of money on maintenance and medical costs.

Another Asian customer was struggling with strict environmental regulations. The DC6060G helped them meet these regulations easily. With its excellent dust control performance, they avoided hefty fines and improved their corporate image in the market.

In conclusion, the DC6060G dry vacuum graphite machining center offers unique advantages in solving the dust pollution problem in graphite machining compared to ordinary machining centers. Its fully enclosed cover design and powerful dust collection device not only protect the health of operators but also improve the efficiency and lifespan of the equipment. If you are still struggling with graphite dust pollution in your machining process, it's time to make a change.

Don't miss out on the opportunity to enhance your graphite machining operations. Contact us today to learn more about the DC6060G and how it can transform your business!

Get in Touch