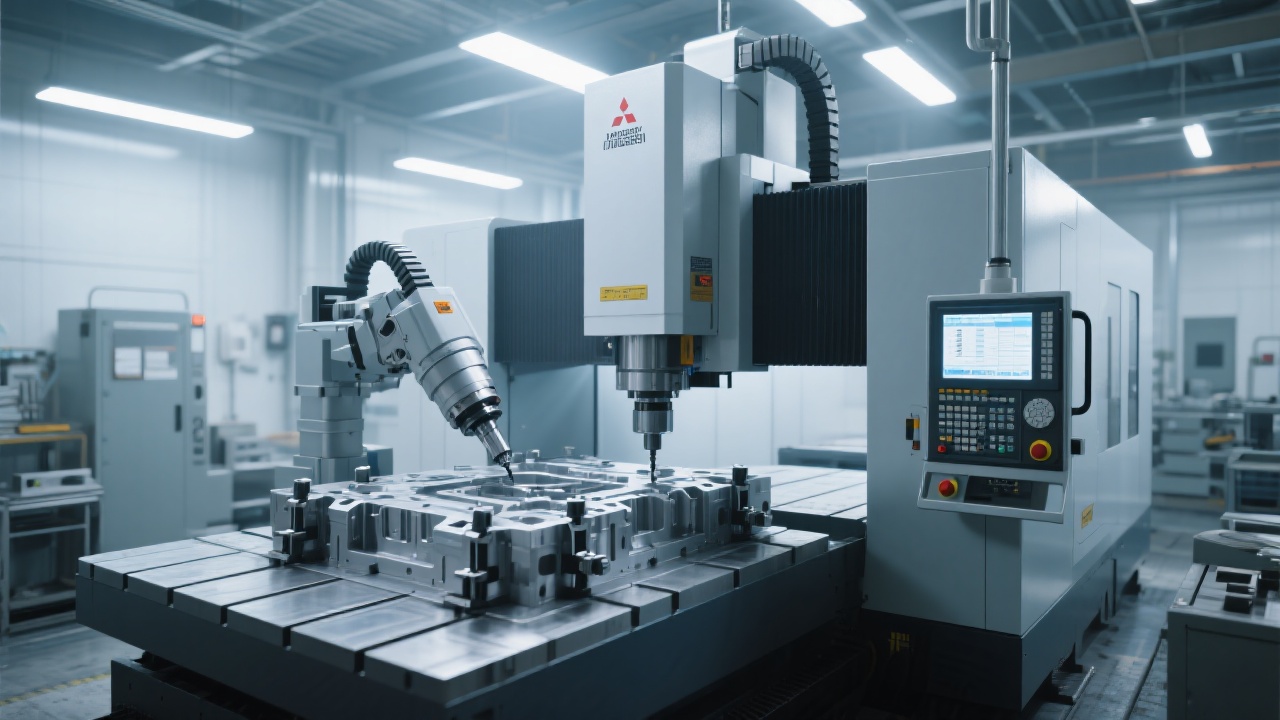

In the graphite machining industry, dust-related corrosion and machining instability remain persistent pain points that frustrate manufacturers worldwide. The DC6060G Dry Vacuum Graphite Machining Center emerges as a game-changing solution by integrating a fully sealed enclosure and an advanced dust extraction system, effectively mitigating these challenges. Its design specifically addresses the harsh dust environments typical in graphite processing, enhancing machine longevity and machining accuracy.

Graphite’s fine dust particles are notorious for penetrating critical machine components, causing accelerated wear, electrical failures, and compromised precision. Conventional machining centers struggle to maintain stable performance under continuous dust exposure, often leading to increased downtime and maintenance costs. Statistics from top-tier manufacturers indicate that unchecked dust accumulation can reduce machine uptime by up to 25% annually and increase maintenance expenditure by 18%.

Addressing these issues has become a paramount concern, especially for sectors demanding high precision like lithium battery electrode production and semiconductor mold manufacturing. The DC6060G is purpose-built to confront these challenges with a design philosophy focused on dust isolation and vacuum-assisted extraction.

At the heart of the DC6060G lies a full-sealed canopy engineered from corrosion-resistant aerospace-grade aluminum alloys, ensuring robust protection against airborne abrasive particles. This enclosure features integrated sealing gaskets rated to IP66, which collectively prevent dust ingress while allowing easy access for maintenance.

Complementing this is an optimized vacuum dust extraction system with a multi-stage filtration mechanism. Using high-capacity turbo blowers, the system maintains a negative pressure inside the machining chamber, capturing nearly 98% of airborne dust particles during operation. This not only preserves component integrity but also upholds a clean working environment, reducing secondary contamination risks.

| Key Technical Parameters | Specification |

|---|---|

| Working Area (mm) | 600 x 600 x 150 |

| Vacuum Pressure (Pa) | -7500 to -8500 (adjustable) |

| Dust Collection Efficiency | Up to 98% |

| Machine Repeatability (μm) | ±2 |

The DC6060G has been successfully deployed in production lines for lithium battery anode electrodes, where dust contamination directly impacts cell performance and yield. One leading Asian battery manufacturer reported a 35% reduction in electrode surface defects after integrating the DC6060G, attributing this to the machine’s dust containment and precision stability.

Similarly, in the semiconductor sector, where mold accuracy is critical to chip performance, the DC6060G’s ability to sustain ±2 μm repeatability under continuous operation helped a European tooling company reduce mold rework by 28%, translating into shorter time-to-market.

Interestingly, these gains also reflect in cost savings: customers report up to 20% lower annual maintenance costs due to reduced abrasive wear on mechanical components, and machine uptime improvements exceeding 12%. Such operational advantages mark the DC6060G as a distinct competitive edge in demanding graphite machining environments.

Proper upkeep is crucial for sustaining performance. The DC6060G’s modular dust collection filters are user-replaceable within 15 minutes, and the vacuum system includes an automated self-cleaning cycle to minimize downtime. Recommended monthly inspections focus on seal integrity and filter efficiency, safeguarding the full sealing principle.

The manufacturer also provides a comprehensive FAQ covering typical concerns—like vacuum parameter adjustments and troubleshooting dust extraction anomalies—coupled with remote diagnostic support that reduces service response time by 40%. Such after-sale support ensures users experience consistent reliability.

Would you like to elevate your graphite machining operations with the DC6060G and experience precision and reliability like never before? Discover how industry leaders gain competitive advantage here »