In the highly specialized industry of graphite machining, precision and equipment durability are paramount. Graphite’s unique properties, such as its brittleness and tendency to generate fine dust particles, pose significant challenges to conventional milling machines. Contamination from graphite dust and metal debris often accelerates corrosion and degrades machine accuracy, leading to frequent maintenance and production downtime.

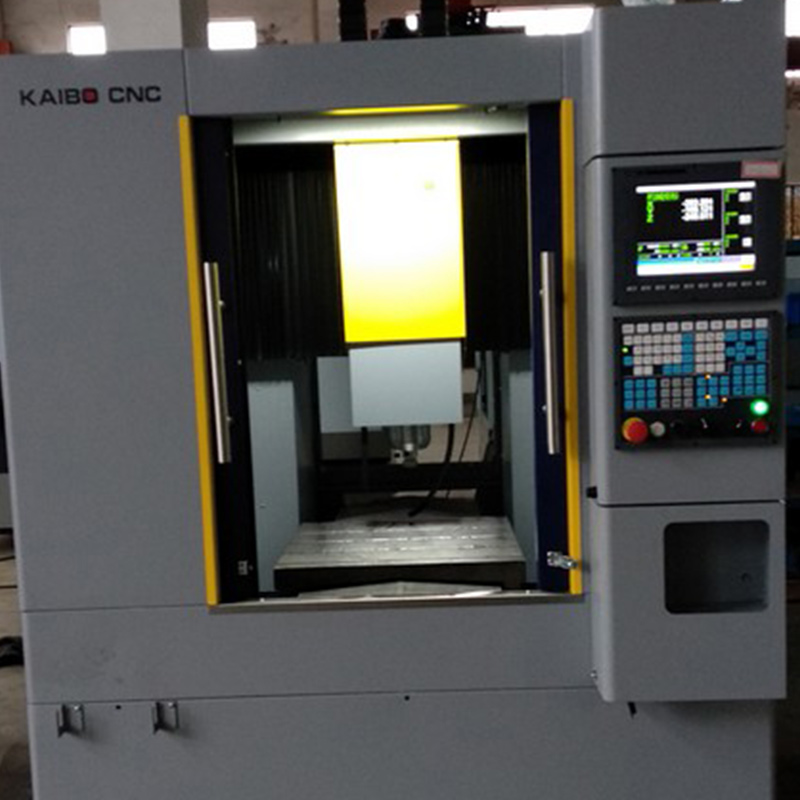

The DC6060G CNC milling machine, developed from the trusted DC6060A model, introduces transformative innovations specifically tailored for graphite processing. Incorporating a fully sealed enclosure and a state-of-the-art wet flushing system, the DC6060G effectively mitigates dust infiltration and corrosion risks, resulting in superior machining precision and longer operational lifespan.

Graphite machining often brings these major concerns for manufacturers:

Recognizing these pain points, the DC6060G was engineered to deliver a targeted solution without compromising ease of use or versatility.

Building on the proven CNC milling foundation of the DC6060A, the DC6060G integrates:

| Feature | DC6060A | DC6060G |

|---|---|---|

| Sealed Enclosure | No | Yes |

| Wet Flushing System | No | Yes |

| Machining Tolerance | ±0.02mm | ±0.01mm |

| Average Maintenance Interval | 6 months | 12 months |

Several graphite processing companies have adopted the DC6060G with remarkable results:

“Since upgrading to the DC6060G, we’ve noticed a 30% increase in machining precision and a 50% reduction in unplanned downtime caused by dust contamination. The wet flushing system keeps the workspace clean, and the sealed enclosure means less corrosion. This machine has improved both our quality and output significantly.”

– Operations Manager, Graphite Components Ltd.

Another leading firm reported:

“The productivity boost was immediate. Not only did we cut tool replacement costs by over 40%, but machine longevity has extended well beyond our previous expectations.”

– Production Director, CarbonTech Manufacturing

The DC6060G stands out by perfectly addressing graphite machining challenges through robust design and intelligent technology integration. Its key advantages include:

Are you ready to transform your graphite machining process with cutting-edge technology? Experience the comprehensive benefits of the DC6060G CNC milling machine and stay ahead in an increasingly competitive market.

Request a Detailed Consultation or Demo

What specific machining challenges are you encountering in your graphite production line? Feel free to reach out and discover how the DC6060G can be tailored to your unique needs.