As global demand for high-performance graphite components continues to rise, manufacturers face increasing pressure to maintain both production efficiency and product quality. One of the most persistent challenges in the graphite machining industry is dust pollution, which not only affects the working environment but also compromises precision and safety. The DC6060G wet-flushing graphite machining center has emerged as a game-changer, offering a comprehensive solution that addresses these critical issues.

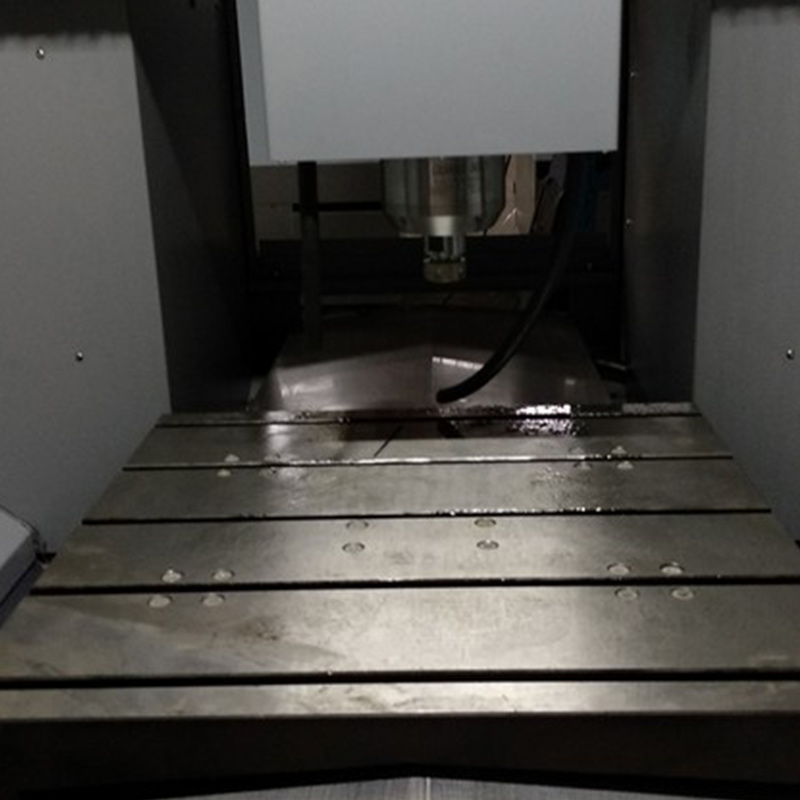

The DC6060G is an advanced evolution of the DC6060A CNC milling machine, incorporating structural improvements to better suit the specific needs of graphite processing. With enhanced rigidity and stability, the machine delivers superior cutting performance while maintaining long-term reliability. This upgrade ensures that users can achieve higher productivity without sacrificing precision or durability.

A key innovation of the DC6060G is its full-sealed enclosure system, which effectively isolates the machining area from the surrounding environment. Unlike traditional machines that allow fine graphite particles to escape into the air, this design significantly reduces airborne dust levels. In one customer site, after implementing the DC6060G, the facility reported a 75% reduction in dust accumulation within the workshop, leading to improved workplace safety and reduced maintenance costs.

The wet-flushing system is another core feature of the DC6060G, designed to remove chips and debris during the machining process. By continuously flushing the cutting area with a controlled water flow, the system prevents chip buildup, ensuring smooth operation and reducing tool wear. This results in longer tool life and faster cycle times. According to internal testing, the wet-flushing function improves machining efficiency by up to 30%, making it a valuable asset for high-volume production environments.

One of the early adopters of the DC6060G is a leading manufacturer specializing in graphite components for the semiconductor industry. Prior to the upgrade, the company struggled with frequent machine downtime due to dust-related malfunctions and inconsistent part quality. After replacing their old equipment with the DC6060G, they experienced a marked improvement in both operational efficiency and product consistency. The company reported a 40% increase in monthly output and a significant drop in rework rates, directly contributing to cost savings and customer satisfaction.

| Metric | Before DC6060G | After DC6060G |

|---|---|---|

| Dust Accumulation | High | Low |

| Tool Life | Shorter | Extended |

| Production Output | Lower | Higher |

The DC6060G wet-flushing graphite machining center stands out in the market for its innovative design, efficient dust control, and proven performance in real-world applications. By addressing common pain points such as dust pollution and tool wear, it offers a robust solution that enhances both production efficiency and product quality. For manufacturers seeking to stay competitive in the evolving graphite machining industry, the DC6060G represents a smart investment.

If you are looking for a reliable and high-performing graphite machining solution, we invite you to learn more about the DC6060G. Our team is ready to provide detailed information and support to help you make an informed decision.

Discover More About DC6060G