In the graphite processing industry, dust pollution has long been a major concern for manufacturers. Fine graphite particles and metal shavings not only pose health risks to workers but also damage equipment and reduce overall production efficiency. Traditional machining solutions often fail to provide an effective and sustainable way to address these issues. However, with the introduction of the DC6060G Wet Cleaning Graphite Machining Center, one factory successfully overcame these challenges and significantly improved their operational performance.

Graphite is widely used in industries such as electronics, aerospace, and automotive manufacturing due to its excellent thermal and electrical conductivity. However, during the machining process, fine dust particles are generated continuously. According to a 2023 industry report, approximately 70% of graphite processing plants experience severe dust-related problems that affect both worker safety and machine longevity.

In addition, metal shavings from cutting tools can mix with graphite dust, causing corrosion and wear on sensitive components. This leads to frequent maintenance, higher downtime, and increased operational costs. For many factories, this issue was a constant struggle—until they discovered the DC6060G.

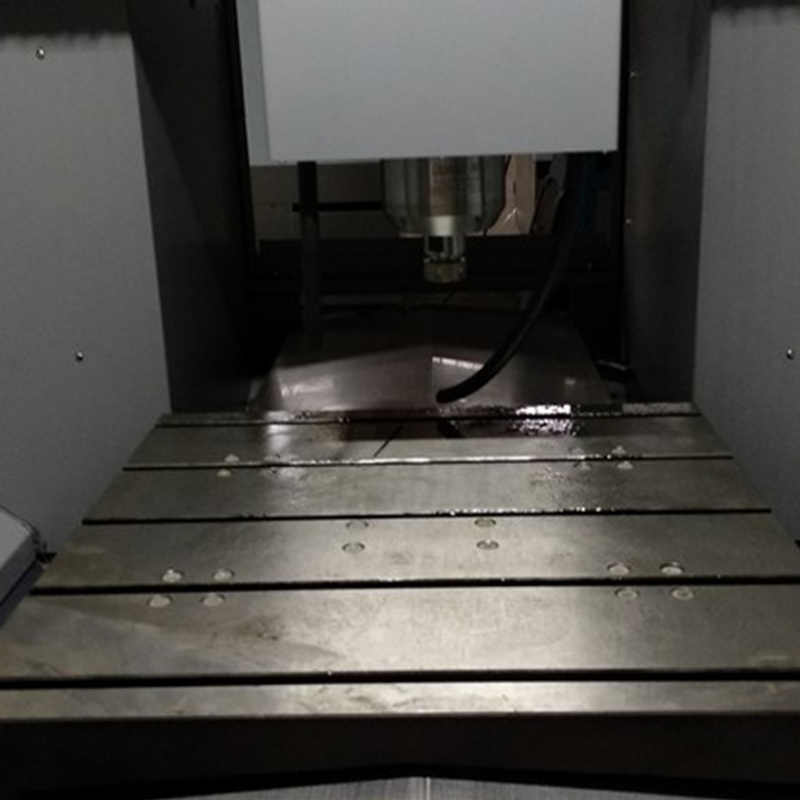

The DC6060G is an advanced upgrade of the DC6060A CNC milling machine, specifically designed for graphite processing. It integrates two key innovations: the full-sealed enclosure and the wet cleaning system. These features work together to prevent dust and debris from escaping into the workspace and to protect the machine from corrosion.

The full-sealed enclosure acts as a protective barrier, containing all dust and shavings within the machining area. Meanwhile, the wet cleaning system uses a controlled water spray to capture and remove fine particles in real-time. This combination ensures a cleaner, safer, and more efficient working environment.

A leading graphite processing factory in China faced persistent dust and corrosion issues with their existing machinery. After switching to the DC6060G, they reported significant improvements. Here’s what they experienced:

| Metric | Before DC6060G | After DC6060G |

|---|---|---|

| Dust Levels | High (visible in air) | Significantly Reduced |

| Machine Maintenance Frequency | Every 2 weeks | Every 6 months |

| Production Efficiency | Low due to downtime | Improved by 30% |

“Since we implemented the DC6060G, our workshop environment has become much cleaner, and our machines last longer,” said the factory manager. “We’ve seen a measurable increase in productivity and a reduction in maintenance costs.”

Compared to traditional graphite processing equipment, the DC6060G offers several competitive advantages:

If you're looking for a reliable and innovative solution to combat dust and corrosion in your graphite processing operations, the DC6060G is the ideal choice. With proven results and a strong track record, it delivers real value to manufacturers across various industries.

Don’t miss out on the opportunity to improve your workshop conditions and boost productivity. Discover how DC6060G can transform your graphite processing today!