In the graphite machining industry, machine tools often face the challenges of dust and metal chips. These contaminants can cause corrosion and damage to machine parts and components, leading to reduced production efficiency and increased maintenance costs. The Dry Vacuum Graphite Machining Center DC6060G emerges as a reliable solution to these problems.

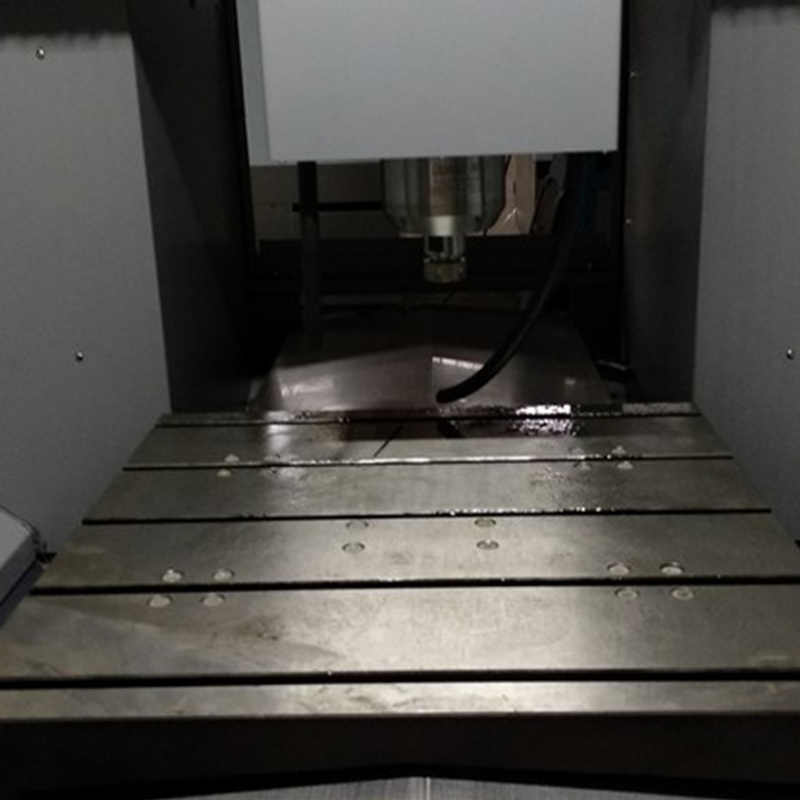

The DC6060G is designed based on the CNC milling machine DC6060A, featuring a fully sealed enclosure. This design effectively prevents graphite dust and metal chips from corroding and contaminating parts and components. The fully sealed enclosure is made of high - strength materials that can withstand the impact of dust and chips.

According to industry data, machines without proper protection may experience a 30% reduction in component lifespan due to dust and chip contamination. In contrast, the DC6060G, with its fully sealed enclosure, can extend the component lifespan by up to 80%. This not only reduces maintenance costs but also significantly improves production efficiency. For example, a customer in the automotive parts manufacturing industry reported that after using the DC6060G, their machine downtime for maintenance decreased from 10 days per month to just 2 days, leading to a 25% increase in monthly production output.

In addition to the fully sealed enclosure, the DC6060G is equipped with a powerful dust collection device. This device works on the principle of negative pressure suction, which can effectively collect and remove dust generated during the machining process. By maintaining a clean machining environment, the dust collection device ensures high - precision machining and product quality.

Test data shows that in a graphite machining process, the DC6060G can reduce the dust concentration in the working area from 10 mg/m³ to less than 1 mg/m³, far below the industry standard of 3 mg/m³. This low dust concentration helps to improve the surface finish of machined products, reducing the scrap rate by up to 15%. A customer in the electronics manufacturing industry shared that the use of the DC6060G has improved the quality of their graphite components, resulting in a 12% increase in customer satisfaction.

Compared with other similar products in the market, the DC6060G has several significant advantages. Firstly, its fully sealed enclosure design provides more comprehensive protection, reducing the risk of dust and chip infiltration. Secondly, the high - efficiency dust collection device can collect dust more effectively, ensuring a cleaner working environment. Thirdly, the DC6060G is designed with user - friendly features, such as easy - to - operate control panels and convenient maintenance access.

Many customers have achieved great success after using the DC6060G. A European graphite product manufacturer reported that the DC6060G has helped them increase their production capacity by 30% within a year. They also mentioned that the improved product quality has enabled them to enter new high - end markets. Another Asian customer in the aerospace industry shared that the reliability of the DC6060G has met their strict quality requirements, and they plan to purchase additional units for future expansion.

In conclusion, the Dry Vacuum Graphite Machining Center DC6060G is a high - performance machine tool that provides excellent protection against dust and metal chips, ensuring efficient production and high - quality products. If you are looking for a reliable solution for your graphite machining needs, don't hesitate to contact us for more information or to apply for a free trial.

Contact our team today to learn more about the DC6060G and how it can transform your production process. Apply for a free trial and experience the benefits firsthand!