Graphite machining presents unique technical challenges that impact production efficiency and product quality. Issues such as pervasive graphite dust infiltration, abrasive metal particles, and contamination threaten the longevity of machine components and compromise workpiece precision. These operational difficulties often lead to increased downtime, maintenance costs, and inconsistent output quality, creating barriers for manufacturers looking to maintain competitive advantage in industries like aerospace, electronics, and automotive.

The DC6060G wet graphite machining center inherits and elevates design principles from the proven DC6060A CNC milling platform, combining decades of engineering excellence with modernization tailored specifically for graphite processing. This integration ensures a balance between rugged mechanical reliability and precision control, delivering a platform optimized for both high throughput and fine detail work.

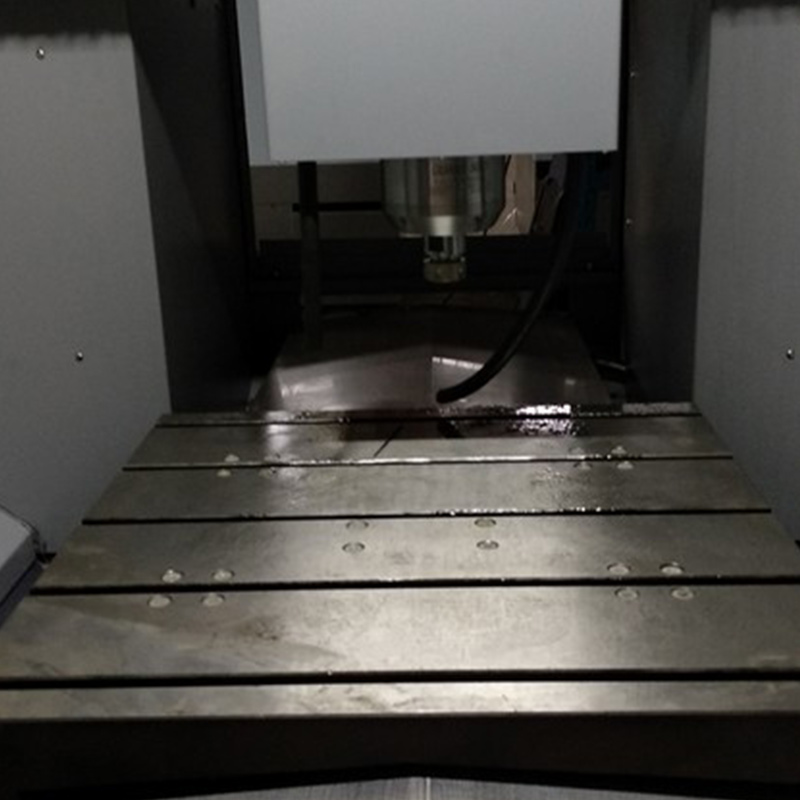

A major innovation of the DC6060G lies in its full-sealed enclosure design. Unlike traditional graphite machining centers that suffer from dust ingress and corrosive wear on sensitive components, the DC6060G’s advanced enclosure hermetically protects critical mechanical and electronic parts from graphite dust and metallic debris. Independent laboratory comparisons indicate that machines without sealed structures experience component wear rates up to 35% higher within 12 months of graphite processing operations.

The fully sealed design ensures that dust and contaminants are contained within designated areas and do not circulate freely, greatly reducing cleaning frequency and maintenance costs. This results in improved uptime reliability and consistent machine accuracy.

Complementing the sealing innovation, the DC6060G features an advanced wet flushing system engineered to actively remove graphite dust and metallic chips during machining. High-pressure fluid jets are strategically positioned to flush debris from critical cutting zones without interfering with machine operation.

Field data demonstrates that this wet flushing reduces particulate accumulation by more than 50% compared to dry systems, contributing to enhanced tool life, reduced thermal distortion, and higher surface finish quality. The continual debris removal also fosters a cleaner shop floor environment, mitigating operator health risks related to graphite dust inhalation.

One leading aerospace component manufacturer implemented the DC6060G to address their chronic graphite dust contamination and inconsistent part tolerances. After integrating the DC6060G into their production line, they reported:

| Performance Metric | Before DC6060G | After DC6060G |

|---|---|---|

| Downtime due to Dust-Related Maintenance | 12 hours/month | 4 hours/month |

| Part Dimensional Accuracy | ±12 microns | ±5 microns |

| Tool Life (Graphite Cutting) | 150 hours | 270 hours |

The DC6060G wet graphite machining center offers a proven solution to the toughest graphite machining challenges through:

Interested in enhancing your graphite machining efficiency and reliability?

Contact Our Sales Team Today

What is your biggest challenge with graphite machining? Reply to our contact team or join our upcoming webinar for an in-depth Q&A session!